Ever wondered What is an Oil Skimmer and How Does it Work? or how we clean our water after an oil spill? The answer is an oil skimmer. It’s a key tool that uses oil recovery tech to pull oil off water surfaces. This is crucial for keeping our environment safe.

Oil skimmers work because oil is less dense than water. This makes it float and easy to pick up. But what makes them so good, and which ones are best for different situations? Let’s explore the world of oil skimmers and see how they help keep our waterways clean.

Key Takeaways

- Oil skimmers use specific gravity and surface tension for efficient oil removal from water.

- There are various types of skimmers, including belt, tube, and disk designs, each tailored for specific applications.

- Choosing the right skimmer type is crucial for effective oil recovery and cost efficiency.

- Skimmers can operate effectively in a range of industrial applications to ensure environmental compliance.

- Enhanced accessories and advanced technology optimize the performance of oil skimmers significantly.

- Industrial oil skimming is a cost-effective initial step to separate oil before resorting to more complex treatments.

What is an Oil Skimmer and How Does it Work? Introduction to Oil Skimmers

Oil skimmers are machines that pull oil out of water. They help clean up oil spills and separate oil from water. These devices use different technologies to reduce oil in water, keeping our waterways clean and following the law.

In places like CNC shops, oil skimmers keep coolant systems clean. They remove extra oil, making coolants last longer in machines.

Definition and Purpose

An oil skimmer is a simple device that picks up oil floating on water. It does more than just clean; it helps industries work better by removing oil. Many liquids, like coolants and cutting fluids, benefit from oil skimmers.

Using oil skimmers can save money by cutting down on maintenance and coolant replacements. This is especially true in machining and cutting fluid environments.

Importance in Environmental Protection

Oil skimmers are key to protecting our planet. They remove oil quickly, preventing big environmental problems. This helps industries follow strict environmental rules, avoiding fines and showing they care about the planet.

Having oil skimmers shows a company’s dedication to the environment. They are crucial for any business that wants to reduce its impact on nature.

How Oil Skimmers Function

Oil skimmers work by using the difference in weight and surface tension between oil and water. They have moving parts like belts or tubes. This helps them grab floating oil while letting water flow back into the water body.

Basic Principles of Operation

Oil skimmers rely on oil being less dense than water. This makes it easier to remove oil. The difference in surface tension also helps in this process. Different models can handle different amounts of oil, from 10 to 200 gallons per hour.

Types of Oil Skimmers

There are many types of oil skimmers for different needs. Belt skimmers use a belt to move oil to a collection area. Tube skimmers are great for messy places. Weir Oil Skimmers use a barrier to collect oil. Oleophilic Oil Skimmers attract oil, while Non-Oleophilic ones work in certain situations.

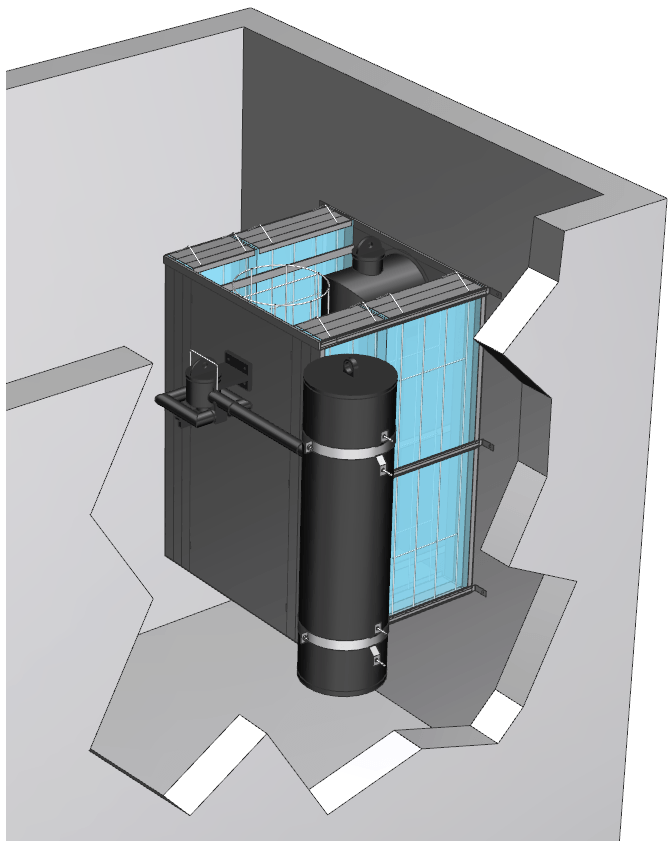

Enhanced Coalescing Technology by Freytech Inc.

Freytech Inc. has led the way in enhanced coalescing technology. This innovation helps oil droplets merge into bigger ones. This makes the oil separation process smoother.

Oil and water separation operations get better, especially when dealing with with emulsified oils.

What Is Enhanced Coalescing?

Enhanced coalescing technology is a big step forward in oil separation. Freytech’s separators can separate oils with high precision. Our standard separators provide below 5 PPM oil outlet concentrations when dealing with free oil. We can even remove mechanically or chemically emulsified oil providing 0.1 PPM oil outlet concentrations.

This is key for industries dealing with trace hydrocarbons. It helps them meet strict regulations.

Benefits of Freytech’s Technology

Freytech’s enhanced coalescing systems offer many benefits. They come with an optional automatic oil skimmer. This skimmer can collect oil with 99.7% purity, making it ready for resale and cutting disposal costs.

Using Freytech’s equipment means less environmental harm and lower maintenance costs. The design is sustainable and the coalescing media is reusable. This technology boosts efficiency and helps protect the environment.

Compliance with Hydrocarbon Discharge Limits

In North America, keeping hydrocarbon discharges under 10 parts per million (PPM) is crucial. This rule is for industries that handle oil and water. Companies need good oil spill cleanup solutions to follow these rules.

Freytech Inc. offers top-notch oil skimming technologies. They meet and often beat the standards, getting as low as 5 PPM. For emulsified oils, they can get down to 0.1 PPM.

Understanding North American Regulations

North American rules are set to keep water clean by limiting hydrocarbon spills. Following these rules is key to protecting our environment and health. Places like waste treatment and manufacturing must use effective cleanup methods.

By sticking to these rules, companies can lessen their environmental harm. They can also keep their operations running smoothly.

Freytech’s Separation Efficiency

Freytech is all about leading in oil separation. Their tech fits different industrial needs, working well even in tough situations. This helps industries lower hydrocarbon levels, making them more compliant with discharge limits.

As we focus more on being green, Freytech’s oil skimming tech is vital. It helps companies stay within the law and help the environment.

Contact Freytech Inc. for More Information

Freytech Inc. is here to help with your oil recovery needs. Our team is ready to give you all the details about our oil skimming solutions. If you have questions or need help, call us at +1 (305) 372-1104. We’re here to make sure you get the right equipment for your work.

Get in Touch at +1 (305) 372-1104

Reaching out to Freytech means tapping into a wealth of knowledge about oil skimmers. Contact us for a consultation or to learn how our oil water separators can improve your operations. We focus on high separation efficiency and reducing hydrocarbon discharge.

Additional Resources on Oil Skimmers

Freytech Inc. has a lot of resources for you, like technical documents and case studies. These resources show how our equipment works well in industrial settings. By choosing our separators, you boost your efficiency and follow sustainable and regulatory standards.

For more on Freytech’s oil skimming solutions, call them at +1 (305) 372-1104. Or check out their resources, like technical guides and case studies.