Ever thought about How to Install a Below Ground OWS? or how a below ground oil-water separator helps our environment? It’s key for meeting strict hydrocarbon discharge rules. This guide will show you how to install one and why it’s important for keeping our environment clean.

Following a proper underground OWS installation guide is crucial. It helps keep operations running smoothly and follows the law. You’ll learn about important details like tank size and how to keep it from leaking. We’ll also cover the need for leak detection systems to spot even the smallest leaks.

Key Takeaways

- Understanding the vital role of below ground oil-water separators in environmental protection.

- Learning how to install a below ground OWS to meet legal compliance requirements.

- Familiarizing yourself with installation specifications and tank capacities.

- The significance of maintenance protocols for ensuring OWS efficiency.

- Insight into the complexities of leak detection and monitoring systems.

Understanding Below Ground Oil-Water Separators

Below ground oil-water separators are key in managing wastewater with oils. These tanks are hidden underground. They use oil’s natural buoyancy to separate it from water, based on gravity.

They have many uses, helping industries deal with oil in their waste.

What is an Oil-Water Separator?

An oil-water separator removes oils from wastewater. It targets harmful contaminants like cooking oils and industrial lubricants. These systems use gravity to remove a lot of oil and sludge.

Keeping oil content under 10 parts per million is crucial. It meets environmental standards and regulations.

Importance of OWS in Environmental Protection

Oil spills can harm ecosystems and threaten plants and animals. Rules like North American hydrocarbon discharge limits show the need for oil-water separators. These systems prevent oil from polluting waterways.

They protect ecosystems and public health, playing a big role in environmental protection.

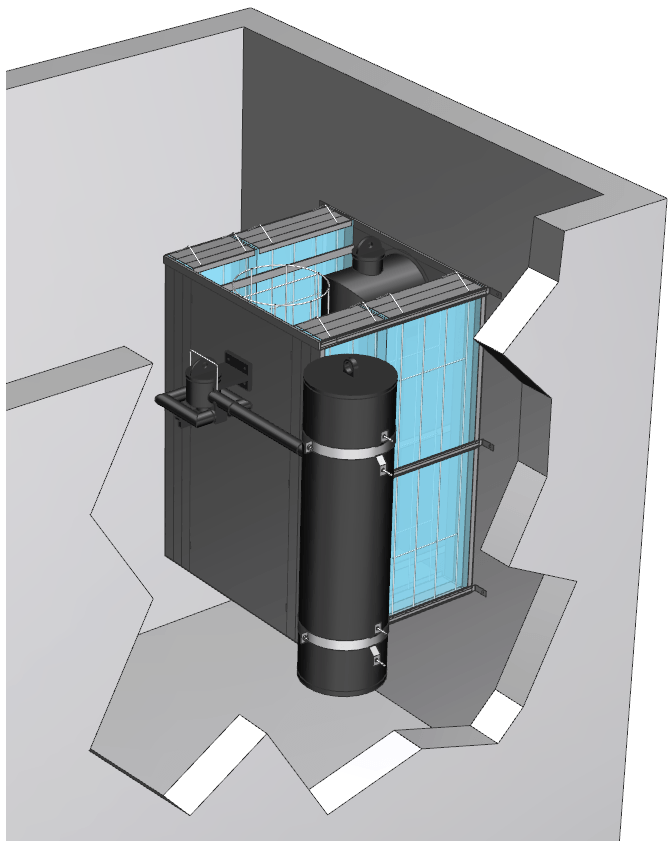

Benefits of Freytech Below Ground OWS

Freytech’s Below Ground OWS offers big advantages for both businesses and the environment. It uses advanced engineering to work better, especially with its special coalescing technology. This tech helps separate oil and water more effectively.

Enhanced Coalescing Technology

Freytech’s coalescing tech is top-notch for catching many pollutants like motor oil, diesel, and jet fuel. It’s so good that it can find hydrocarbons down to 0.1 parts per million. This means cleaner water and better environmental health.

Improved Separation Efficiency

Using Freytech’s below ground OWS can really cut down on harmful discharges. People have seen hydrocarbon discharges drop by up to 95%. It meets strict standards, keeping water sources clean and safe.

Compliance with North American Hydrocarbon Discharge Limits

Knowing about hydrocarbon discharge limits is key for businesses wanting to follow environmental rules. North America has strict PPM standards. The maximum allowed discharge is 10 parts per million (PPM). This protects water sources from industrial harm.

Companies need to follow these rules to lessen their environmental footprint. This ensures they meet legal requirements.

Understanding PPM Standards

PPM standards set the max hydrocarbon levels in water discharge. Knowing these limits helps companies use the right tech to follow rules. Freytech Inc. has a cutting-edge oil-water separator (OWS) tech.

This tech can cut hydrocarbon levels down to 5 PPM. It goes beyond the required limits, showing a strong commitment to the environment.

Advantages of 5 PPM vs 10 PPM

Going for a 5 PPM discharge has big pluses over the 10 PPM standard. A 5 PPM goal means better environmental protection. It lowers the chance of water pollution.

Using Freytech’s OWS tech also boosts work efficiency and can save money. These benefits show a company’s dedication to green practices.

Installation Requirements for Below Ground OWS

Knowing what’s needed for a below ground oil-water separator (OWS) is key. A good start is a detailed site assessment for underground OWS. This checks soil, drainage, and nearby structures that could affect the setup. Getting it right ensures a system that lasts and works well.

Site Assessment and Preparation

Doing a thorough site check for underground OWS is essential. It looks at the soil and its strength to hold the separator. It also checks groundwater and drainage to make sure it works right. Not paying attention to these can cause problems later.

So, careful planning at the start saves time and money later.

Permitting and Regulations

Getting the right permits is crucial for oil-water separator systems. Local laws often need notices and approvals before you start. Rules like NFPA and OSHA guide how to dig and keep things safe.

The Resource Conservation and Recovery Act also requires telling authorities about certain tanks. Following these rules protects the installation, the environment, and people’s safety.

Step-by-Step Installation Process

Installing a Below Ground Oil-Water Separator (OWS) needs careful attention and following best practices. The process includes several key steps. These are excavating for underground OWS, installing the system, and connecting it to drainage systems.

Excavation and Site Setup

Start by assessing the site to find the best spot for the OWS. Follow the manual’s excavation guidelines to make sure the site is right. The backfill material must be strong enough to support the OWS.

It’s crucial to fill the OWS with clean water before using it. This ensures it works well from the start. Make sure the excavation is deep enough for all parts and for good drainage.

Installing the OWS System

After digging, it’s time to put in the OWS system. Stick to the manufacturer’s instructions for top performance and safety. Make sure all parts, like oil skimmers and sensors, are in the right place.

Connect any alarms for easy monitoring. Do a test run before finishing to catch any problems. Also, think about how detergents or solvents might affect the OWS’s performance.

Connecting to Drainage Systems

The last step is linking the OWS to drainage systems. Follow the rules for piping and venting to avoid problems later. Keep a record of all steps and checklists to make sure everything is done right.

Having the OWS User’s Manual handy is important. This way, you can follow the right steps and avoid future problems.

Maintenance and Monitoring Best Practices

Keeping underground OWS in top shape is key for good performance and following environmental rules. Regular checks help spot problems early, making oil-water separators last longer and work better.

Regular Inspection Schedules

Below Ground OWS units need checks every 180 days. This helps catch sludge buildup early, which can slow down the system. Cleaning the coalescer plates regularly keeps things running smoothly.

Tools like high oil level alarms and oil stop valves help avoid overflows. They make sure the system stays within legal limits.

Troubleshooting Common Issues

When fixing oil-water separator systems, knowing common problems is crucial. This includes equipment failures or poor separation. Making sure the separators are in the right place and well-maintained boosts performance and follows environmental laws.

Fixing problems fast can save money and make operations more reliable.

Contact Freytech Inc. for Expert Assistance

Getting help from experts is key for underground oil-water separators. Freytech Inc. offers nine models to fit different needs. They make sure you meet environmental standards.

Schedule a Consultation

Freytech’s team is ready to help you. They can guide you through choosing the right model. Whether it’s the EcoSorp or EcoLine B, they’ll help you find the best fit. Contact them to see how their technology can help your environmental goals.

Reach Us at +1 (305) 372-1104

Need help right away? Call Freytech Inc. at +1 (305) 372-1104. We’re committed to your success and the environment. Let us help you with oil and water separation, making your business better and greener.