Efficient Oil Water Separation Technology for West Lincoln NE

In West Lincoln NE, industrial sites depend on an effective oil water separator. These are essential to meet environmental rules and avoid expensive waste disposal. Freytech Inc. provides advanced Oil Water Separator West Lincoln NE. They remove hydrocarbons like motor oil and gasoline from water.

Our OWS use enhanced coalescing technology for better separation. This is more effective than traditional interceptors or oil traps. With nine different models, Freytech Inc. delivers both above-ground and below-ground solutions. These are tailored for various industries with individual environmental needs.

Freytech is known for reliable, durable separators. Choosing our solutions means getting top technology and our help to keep operations safe and compliant. We have significant field experience and know how to improve efficiency and protect the environment. Our team is here to help from start to finish, from the first consultation to installation and beyond.

Key Takeaways

- High-Efficiency Separation: Freytech’s Oil Water Separator West Lincoln NE deliver up to 5 PPM and 0.1 PPM for emulsified oils, ensuring clean, compliant discharge.

- Nine Specialized Systems: From above-ground to below-ground and containerized options, each model is built for different operational needs.

- Environmental and Economic Benefits: Our separators lower waste management costs, offer pure, recyclable oil, and help companies stay compliant with environmental standards.

Advantages of Freytech Oil Water Separator West Lincoln NE

Unlike conventional oil traps or interceptors, Freytech’s Oil Water Separator West Lincoln NE provide leading technology. Each separator has reusable coalescing media that needs little upkeep. This means long-term performance without the high cost of extraction services. Our optional automatic oil skimmer makes operations easier by collecting nearly 99.7% pure oil, ready for recycling.

Freytech’s products support companies meet safety and sustainability goals. Oil water separators are essential in reducing the environmental impact of industries that handle hydrocarbons. By choosing innovative separation technology, companies help keep clean waterways and ecosystems. This move is more than just following rules; it reflects a commitment to environmental responsibility.

Some of the key benefits of using Freytech include:

- High separation efficiency: Our systems achieve up to 5 PPM for non-emulsified oils and can reach 0.1 PPM for emulsified oils.

- Cost-effective: Reusable coalescing media and minimal maintenance requirements deliver long-term savings.

- Eco-friendly: Freytech systems provide compliance with stringent environmental standards, lowering environmental impact.

Types of Freytech Oil Water Separator West Lincoln NE

Freytech Inc. provides nine advanced oil water separator models, each tailored for specific industrial needs. Here’s an overview of each separator:

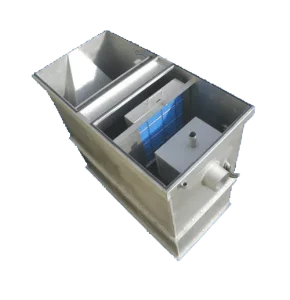

1. EcoLine A

The EcoLine A is an above-ground oil water separator ideal for high-quality separation of non-emulsified light liquids such as gasoline, diesel, and heating oils. This model provides up to 5 PPM separation efficiency and is ideal for fueling stations, garages, and workshops.

2. EcoTop

The EcoTop system is engineered for above-ground use and specializes in managing heavy oils. It delivers high-performance separation for dense hydrocarbons, making it perfect for industrial sites with oil-intensive operations.

3. Containerized Oil Water Separator

For temporary or temporary operations, Freytech’s containerized oil water separators deliver a portable solution. These systems are pre-fitted in standard cargo containers, providing turnkey installations for military bases, remote mining sites, or temporary industrial projects requiring reliable oil water separation.

4. EcoLine B

Our EcoLine B separator is a below-ground system designed for non-emulsified oils and is perfect for high-volume facilities. Known for its resilience, the EcoLine B provides 5 PPM separation efficiency and is designed for operations with significant hydrocarbon management needs.

5. EcoSorp

The EcoSorp model focuses on separating emulsified oils, achieving an impressive 0.1 PPM efficiency. This below-ground separator is essential for industries processing trace hydrocarbons, ensuring compliance with the highest environmental standards.

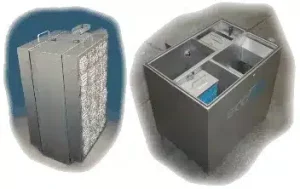

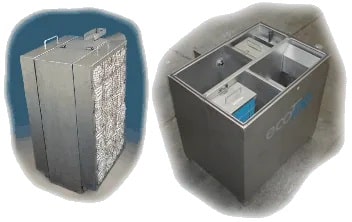

6. High Flow Rate Oil Water Separator

For intensive industrial operations, our High Flow Rate Separator is built with extra-large panel designs to handle significant volumes of oil-contaminated water. This separator delivers consistent performance even under rigorous conditions, making it essential for large-scale facilities.

7. Oil Skimmer

The automatic Oil Skimmer provides an practical solution for removing separated oil. This accessory connects with any Freytech separator, delivering oil with 99.7% purity—ready for resale—while minimizing the costly disposal of oil-contaminated water.

8. EcoStop

The EcoStop oil spill control valve is a important component for spill containment. This valve stops oil from entering wastewater systems, securing the local environment from unintentional spills.

9. EcoGrease

The EcoGrease separator is specifically designed for food-related industries, where it separates grease and oil from wastewater. By preventing grease buildup in plumbing systems, it supports efficient operations and reduces maintenance needs.

How Does An Oil Water Separator Work?

An oil water separator isolates oil from water mixtures. It works because oil is less dense than water. This allows oil droplets to float to the surface.

The contaminated water enters a chamber where it settles. Gravity and coalescing media then extract the oil particles. This process is key to effective separation.

First, a sedimentation chamber filters out larger particles. Then, the water flows across coalescing media. This encourages oil droplets to clump together.

These larger droplets float to the surface. They can then be skimmed or drained off. This provides clean water discharge.

Some OWS, like those from Freytech, include an automatic oil skimmer. This continuously removes oil, maximizing separation. The cleaned water is then discharged, often meeting environmental standards.

This process is efficient and sustainable. It supports industries to manage wastewater responsibly. Each stage is optimized to maximize oil removal, minimizing environmental impact.

Freytech’s Commitment to Innovation and Customer Support

At Freytech, we’re constantly innovating. Our team works hard to keep our technology leading. We provide our clients the best in oil water separation.

We focus on compliance and sustainable waste management. Our quality assurance guarantees our separators meet high standards. This is before they reach our clients.

We also emphasize customer support. Our team assists in selecting, installing, and maintaining our products. We offer ongoing support to maximize our products’ benefits. This makes Freytech more than a vendor; we’re a partner in environmental stewardship.

Why Separate Oil and Water

It’s necessary to separate oil from water for the environment, meeting regulations, and keeping industries running well. Oil mixed with water is common in many fields, like transportation, manufacturing, and food production. If they’re not removed, this mix can contaminate waterways and threaten aquatic life.

Oil in water also contaminates our drinking water and can be hazardous to ecosystems. This is why it’s so essential to keep them apart.

Oil and water mixtures are also governed by government agencies. Places have rules about how much oil can be in water. For example, in North America, it’s usually no more than 10 parts per million. Companies that comply with these standards minimize legal risks and preserve their public image.

Also, separating oil and water enables industries reduce costs and conserve resources. They can resell or reclaim valuable oil they get back. This is good for the planet and can even generate income.

Freytech’s oil water separator West Lincoln NE is industry-leading. They provide water is clean and safe to dispose of. By implementing these solutions, companies prioritize sustainability. This is important for safeguarding ecosystems and meeting rules.

Benefits of Freytech Oil Water Separator West Lincoln NE

Freytech’s Oil Water Separator West Lincoln NE deliver many advantages. They support industries in West Lincoln NE stay compliant with environmental regulations. They also manage hydrocarbon waste economically and efficiently.

Compliance with Environmental Standards

Most regions enforce hydrocarbon discharge limits of 10 PPM or less. Freytech’s separators meet and exceed these standards. They achieve 5 PPM or even 0.1 PPM for emulsified oils, ensuring clean discharge.Reduced Maintenance Costs

Our OWS call for minimal intervention. The reusable coalescing media can be easily spray-washed. This lowers the need for costly disposal and extraction services.Versatile Applications

We have above-ground, below-ground, and containerized options. This flexibility enables companies to choose the ideal separator for their needs.Reusable Skimmed Oil

With our optional automatic oil skimmer, companies can collect oil at 99.7% purity. This pure oil is suitable for resale.Eco-Friendly and Sustainable

Freytech’s separators protect local ecosystems. They help businesses reduce their environmental footprint by separating hydrocarbons from water efficiently.

Conclusion

Freytech Inc.’s Oil Water Separator West Lincoln NE lead the way in oil separation. They provide nine models, advanced tech, and proven designs. This enables companies achieve compliance, save money, and reduce waste.

Whether you run a fuel station, Freytech has you covered. Contact us today to see how Freytech Oil Water Separator West Lincoln NE can boost your operations.

Contact us for more information to learn how Freytech Oil Water Separator West Lincoln NE enhance your operations.

Frequently Asked Questions (FAQs)

1. How do Freytech’s oil water separator West Lincoln NE apart from other brands?

Freytech OWS West Lincoln NE utilize enhanced coalescing technology that ensures superior separation efficiency, achieving 5 PPM and 0.1 PPM for emulsified oil. This supports compliance with stringent environmental standards, saving on waste disposal.

2. How easy are Freytech oil water separators to maintain compared to others?

Yes, Freytech separators are equipped with reusable coalescing media that need simple spray-washing. This effectively reduces operational costs and ensures the system remains over time.

3. Can emulsified oils?

Yes. The EcoSorp separator is specifically engineered to handle emulsified oils with purity levels as high as 0.1 PPM, ensuring clean discharge for complex hydrocarbon mixtures.

4. Is there a portable option for oil water separator West Lincoln NE?

Yes, our Containerized Oil Water Separators are a flexible, all-in-one solution. They’re perfect for remote or temporary setups on West Lincoln NE. These systems come in cargo containers for efficient deployment.

5. Is the separated oil reusable?

Yes. With the Automatic Oil Skimmer, Freytech systems deliver oil at 99.7% purity, making it valuable for reuse and eliminating the costs of waste oil disposal.