Have you thought about How to Install an Above Ground Oil Water Separator? or how important it is to install an above ground oil water separator right? These separators are key for businesses that make wastewater. They make sure harmful hydrocarbons are taken out before water goes back into nature. Knowing how to set up an oil water separator is critical, as there are strict rules about hydrocarbon discharge.

This article will explain why proper installation is so important. It will also give you a step-by-step guide to help you set up your oil water separator.

If you want to learn more about the technical side of oil water separators, check out this link.

Key Takeaways

- Understanding how oil water separators work is key to following discharge rules.

- Installing them correctly makes them work better at removing hydrocarbons.

- Knowing the rules helps businesses meet their environmental duties.

- Picking the right model is important for flow rates and oil holding capacity.

- Keeping them maintained is vital for their long-term performance.

- Using the latest technology can make oil recovery systems even more efficient.

Understanding Oil Water Separators

Oil water separators are key in managing water contaminated with oil. They are made to separate oil and grease from water, meeting environmental rules. Knowing how they work means understanding their purpose, parts, and how they operate.

What is an Oil Water Separator?

An oil water separator is a tool for treating rainwater and wastewater. It separates and holds light liquids with a density less than 0.95 g/cm³. As rules get stricter, having a good oil water separation process is more important than ever.

There are different types like gravity, coalescing, and centrifugal separators. They make sure water is clean before it’s released.

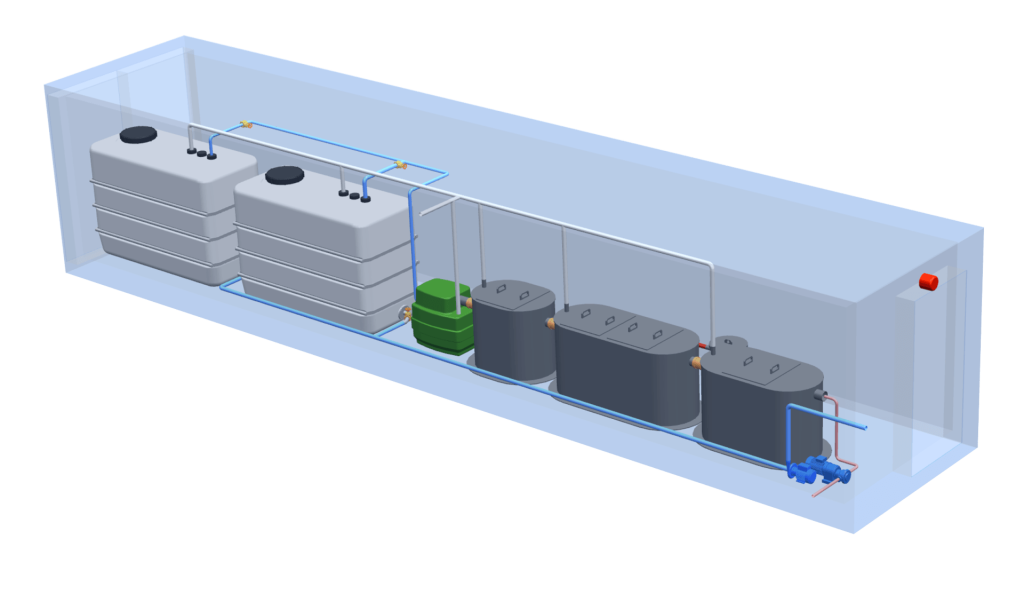

Key Components of an Oil Water Separator

The parts of an oil water separator system are vital for its work. It has a chamber for settling liquids, coalescing media for oil droplets, and outlets for clean water. Each part is important for efficient separation and meeting standards.

How It Works: The Separation Process

The separation process relies on gravity and buoyancy. Oils and lighter hydrocarbons float on top because they’re less dense than water. This lets us collect the oil, and the water below can be safely released.

Modern models, like the Freytech Enhanced Coalescing Oil Water Separator, can separate oils as low as 0.1 PPM. This shows how technology helps protect our environment.

Importance of Compliance with Hydrocarbon Discharge Limits

Following hydrocarbon discharge limits is key for businesses in North America. These rules protect the environment by controlling hydrocarbon releases into water. Companies that don’t follow these rules face legal trouble and harm the environment. Knowing these standards is vital for keeping operations safe and eco-friendly.

Overview of North American Discharge Standards

North American discharge standards say treated water must have less than 10 PPM of hydrocarbons. This rule helps cut down pollution and encourages industries to follow the rules. Freytech oil water separators meet these standards, achieving separation below 5 PPM even with high influent concentrations.

Using these separators helps businesses lessen their environmental footprint.

Freytech’s Commitment to 5 PPM Separation Efficiency

Freytech Inc. is dedicated to protecting the environment with its advanced technology. Its oil water separators handle hydrocarbons with specific gravity from 0.82 to 0.88. They remove contaminants efficiently, with some models reaching 0.1 PPM separation.

This performance goes beyond North American standards. It also helps meet the US EPA’s Clean Water Act, improving stormwater management and ecological safety.

Selecting the Right Location for Installation

Choosing the right spot for an oil water separator is key for good performance and following environmental rules. Several important factors come into play when picking a location. Being close to where the oil comes from is important for the separator’s success. Also, knowing local laws about where you can install is a must.

It’s also vital to think about how the installation might affect the environment. For example, being too close to water bodies can lead to pollution. So, it’s important to pick a spot that won’t harm the environment.

Factors to Consider When Choosing a Site

When picking a site for an oil water separator, think about the area’s layout and height. Make sure the spot allows for good drainage to avoid water buildup. Heavy rain or flooding can mess up the separator’s work and cause more upkeep problems.

Also, think about how easy it will be to get to the separator for upkeep. A spot that’s easy to get to is better for keeping the system running smoothly. A well-chosen spot helps the system work well for a long time.

Accessibility for Maintenance and Servicing

Being able to get to the oil water separator for upkeep is very important. Regular checks and upkeep stop problems before they start, saving money on repairs. If the unit is hard to get to, upkeep might get skipped, leading to bigger problems.

When picking a spot, make sure there’s enough room around the separator. This makes upkeep easier and helps avoid problems with waste and system performance.

Preparing the Installation Area

Getting the installation area ready is key for a successful oil water separator setup. This involves several important steps. You need to pick the right tools and materials, and prepare the site properly.

Required Tools and Materials

First, collect all the tools you’ll need for the installation. You’ll need shovels, levelers, wrenches, and screwdrivers. Also, get valves, pipes, and coalescing media packs for a complete setup. A checklist can help make sure you have everything you need.

Site Preparation Steps

Start by clearing the area of any debris or plants. Make sure the ground is level for a stable base. Setting up a good drainage system is also important to manage water and prevent flooding.

By following these steps, you can avoid future maintenance problems. This will help your oil water separator work better.

Step-by-Step Installation Process

Installing an oil water separator is key for its best performance and meeting environmental rules. It involves three main steps: setting up the separator, linking the pipes, and making sure it’s stable. Here’s a detailed guide on how to do these steps right.

Installing the Separator Unit

First, put the separator in the spot you’ve picked, making sure it’s ready. Make sure it’s on a firm base. For big units like the TS5000 SS, which is 1200mm L x 730mm W x 990mm H and can handle 5000 L/hr, you might need a crane.

Check it’s aligned right. This is vital for a good setup.

Connecting Inlet and Outlet Pipes

After setting up the unit, connect the pipes. Use the right fittings to avoid leaks. Follow the maker’s instructions, as different models need different steps.

Make sure the pipes are straight and not stressed. This keeps everything working smoothly.

Leveling and Securing the Unit

The last step is to level and secure the unit. Use a level to ensure it’s flat. Adjust it if needed to get it right.

Then, lock it down to stop it moving. This makes the separator reliable and keeps it working well.

Utilizing Enhanced Coalescing Technology

Freytech is dedicated to top-notch oil-water separation. It uses advanced coalescing technology. This tech boosts media efficiency by attracting and merging small oil droplets.

This is key to meet North American hydrocarbon discharge limits. It allows for separation down to 5 PPM levels. Even trace amounts of 0.1 PPM for emulsified oils are achievable. Such high standards are essential for industries under strict regulations.

How Freytech’s Coalescing Media Works

Freytech’s separators use special media for better separation. This media attracts oil droplets, helping to remove oil from water. As droplets merge, they rise to the surface for easy extraction.

This patented technology ensures reliable and consistent performance. It minimizes disruptions and risks related to compliance.

Benefits of Reusable Coalescing Media

Freytech’s system stands out for its reusable coalescing media. This media can be cleaned and reused, extending its life and cutting costs. It reduces waste and the need for frequent replacements.

By keeping media efficiency high, users save on costs and maintenance. This makes it a cost-effective choice for oil-water separation.

Adding Optional Features for Improved Efficiency

Adding optional features to an oil water separator can make it work better. Freytech’s patented oil skimmer is a great example. It helps separate oil from water efficiently, reaching up to 99.7% purity. This is key to making the oil water separator more effective.

The Patented Oil Skimmer: An Overview

The patented oil skimmer uses advanced technology for industrial use. It works well with control systems like pumps and sensors. This setup makes it easy to monitor and manage oil collection.

Using this technology boosts collection rates and cuts down on manual work. For more on how to improve these processes, check out this resource.

Benefits of Automatic Oil Drainage

Automatic oil drainage has many benefits. It saves on labor costs by needing less manual work. The system is designed to be easy to use, with digital displays for real-time monitoring.

This makes it easy to fix any issues quickly. It also makes the oil water separator more reliable.

Maintenance Practices for Long-Lasting Performance

Keeping your oil water separator in good shape is key to its long-term success. Regular checks can spot issues like sludge buildup and worn-out parts early. This helps meet strict discharge standards, like MARPOL Annex I, which sets a limit of 15 parts per million (ppm) for bilge water.

Regular Inspection and Cleaning Tips

When you inspect, watch for wear and tear on parts, focusing on the coalescing media. It’s important to clean out any sludge or contaminants that might be there. This keeps the media working well to separate oil from water.

Also, check the discharge levels. If they’re too high, you’ll need to fix the problem right away.

How to Properly Wash Coalescing Media

Cleaning the coalescing media needs a careful method to keep it working right. Use warm water or a gentle detergent to get rid of oil and dirt. Stay away from strong chemicals that could damage the media.

Rinse it well to make sure no cleaning solution is left behind. This helps the media work better next time. Following these steps can really boost how well the oil is separated and avoid expensive downtime.

Understanding the Financial Benefits of Oil Recycling

Investing in oil recycling systems offers big economic benefits that many businesses miss. Practices like oil skimming help save money and meet environmental standards. These are key for today’s industries.

Cost Savings with Efficient Oil Skimming

Oil skimmers are key for handling oil spills and recovery. They recover a lot of oil, saving money in emergencies. They also clean up surface contaminants, helping industries like maritime and manufacturing.

Using skimmers long-term can save money, even after the initial cost. It also helps avoid fines and damage from bad disposal. This is good for both the wallet and the planet.

Recycling Used Oil: Environmental and Economic Benefits

Recycling used oil has big environmental wins. Restaurants can cut disposal costs by up to 40% by recycling cooking oil. Each gallon of recycled oil can make almost a gallon of biodiesel.

This cuts greenhouse gas emissions by up to 50% compared to regular diesel. Following proper disposal rules can also save about 10% on waste management costs. It makes businesses more attractive to customers.

Well-kept grease traps catch most fats, oils, and grease. This lowers plumbing repair costs and boosts efficiency.

Contact Freytech Inc. for Support and Installation Services

Need help with oil water separator installation or ongoing support? You can easily contact Freytech Inc.. Our team is ready to help you with your oil-water separation needs. Call us at +1 (305) 372-1104 for quick and professional help.

How to Reach Us

Looking to install a new oil water separator or need help with your current systems? Freytech offers Freytech support services for your industry. Our team can answer your questions and provide the right info to meet environmental rules and improve performance.

Why Choose Freytech for Your Oil Water Separator Needs?

Choosing Freytech means choosing quality, cutting-edge tech, and great customer service. Our EBD technology has won awards, making us a top choice for oil-water separation. We’re ready to help you solve problems and protect the environment.