Ever thought about What are the Benefits of Using an Oil Water Separator? or how industries separate oil from water while following strict environmental rules? Oil water separators are key to keeping operations green and efficient. They help a lot, from cutting down on fines to making it possible to use oil again in factories. As companies focus more on being eco-friendly, knowing the good of oil water separators is critical for handling wastewater well.

Key Takeaways

- Oil water separators can achieve up to 99% efficiency in separating free-floating oil from water.

- Facilities utilizing these separators can reduce regulatory fines by an estimated 30%.

- Oil reclaimed from separators has the up to 85% reuse in industrial processes.

- Coalescer separators enhance oil recovery rates by improving separation efficiency by up to 50%.

- Modular clarifiers may require 40% less maintenance than traditional systems.

- These devices help industries manage significant oil and grease contamination in wastewater effectively.

Understanding Oil Water Separators

An oil water separator is a vital tool in many industries. It helps meet strict environmental rules. It removes oil from wastewater before it’s released or reused. This is key for companies to follow environmental laws and protect water life.

Definition and Purpose

The main job of an oil water separator is to split oil from water. It uses the difference in their densities. This way, it treats wastewater with oil well.

This treatment is not just for following rules. It also cuts down on the harm oil can do to the environment.

How They Function

Oil water separators work well in handling oily wastewater. They use gravity and coalescing technology. In gravity systems, oil floats up, and clean water comes out below.

Coalescing separators use special media. This helps oil droplets join together, making them easier to remove.

Types of Oil Water Separators

There are different types of oil water separators. Each one is made for certain needs. Gravity-based and coalescing separators are the main types.

Gravity separators use natural differences in density. Coalescing separators are better because they help oil droplets stick together. Choosing the right one is important for following local laws and working well.

Compliance with Environmental Regulations

In North America, following environmental rules is key. Companies must stick to strict hydrocarbon discharge limits. The 10 PPM hydrocarbon limits are a big deal. Not following these rules can cost a lot and limit how a business operates.

North American Hydrocarbon Discharge Limits

The limit for hydrocarbon discharge is 10 PPM. This means companies must have good systems for oily wastewater. If they don’t follow the rules, they could face fines of $25,000 a day. Serious mistakes can make these fines even higher.

Importance of 10 PPM Compliance

Following the 10 PPM rule helps avoid fines and shows a company cares about the environment. Using the right oil-water separator technology can really help. It can cut the chance of oil pollution in water by half, protecting our oceans and lakes.

Benefits of Exceeding Regulatory Standards

Going beyond the 10 PPM limit has many benefits. Companies can save money on wastewater treatment, cutting costs by 20-50%. Plus, being environmentally responsible can make a company look better. This can lead to more customers and a stronger market position.

Enhanced Separation Efficiency

Oil water separators are key for industries to meet environmental standards and protect water quality. Freytech technology uses advanced coalescing methods to boost separation. These systems can achieve a separation efficiency of 5 PPM, meeting strict regulations.

Achieving 5 PPM with Freytech Technology

Freytech’s oil water separators are designed to reach a 5 PPM separation efficiency. This high performance helps avoid costly penalties for non-compliance. Using these separators regularly supports sustainable practices and saves money in the long run.

Emulsified Oil Separation Capabilities

Freytech’s technology excels in removing oils that are hard to treat. Unlike traditional gravity separators, Freytech products can remove oils with over 95% efficiency. This ensures a cleaner effluent stream.

Trace Oil Separation at 0.1 PPM

Freytech separators can separate trace oils at levels as low as 0.1 PPM. This meets and exceeds environmental compliance expectations. The technology also protects water quality, supporting sustainability and operational efficiency.

Versatility in Hydrocarbon Removal

Oil water separators are key in many industries. They remove hydrocarbons from wastewater well. They handle motor oil, gasoline, and jet fuel, keeping the environment safe.

Effective Removal of Motor Oil and Diesel

These separators work great in places with lots of oil, like car repair shops. They remove motor oil well, making sure water is clean and safe.

Treatment of Gasoline and Jet Fuel

Freytech’s advanced separators are made for gasoline and jet fuel. They can handle big flows fast, keeping standards high.

Handling of Refined Hydrocarbons

These systems can handle many types of oil. They help businesses follow environmental rules and keep water clean.

Cost-Effectiveness of Freytech Solutions

Freytech Inc. shows how oil water separators can save money. They use new technologies that help a lot. The reusable coalescing media is a big part of this savings.

Reusable Coalescing Media

Freytech’s solutions use reusable coalescing media. This makes the separators work better and is good for the environment. The media lasts a long time, which means less money spent on replacements.

This leads to less money spent on upkeep. It shows how oil water separators can save money.

Easy Maintenance and Long-Term Use

Maintaining Freytech separators is easy. This means less time and money spent on upkeep. The equipment is built to last, so it works well for a long time.

This means less money spent on fixing things and keeping things running. It’s a big win for industries.

Savings on Disposal Costs

Freytech’s oil water separators save a lot on disposal costs. They keep oil levels low, which means less waste. This means lower fees for getting rid of waste.

This is a big win for companies dealing with oily wastewater. Freytech’s approach is good for the planet and the wallet. It’s a smart choice for today’s industries.

Automatic Oil Skimming Features

Automatic oil skimming features help industries separate oil from water efficiently. Freytech separators use special technology to make oil removal quick and effective. This helps keep operations running smoothly by removing oil contaminants.

Mechanized Oil Separation Process

The mechanized oil separation process helps collect tramp oil on water surfaces. It reduces the impact of oil on coolant systems, making maintenance easier. This leads to less downtime and more productivity for facilities.

Purity of Skimmed Oil at 99.7%

Freytech technology achieves a 99.7% purity in skimmed oil. This high purity makes the oil useful for many applications. It meets industry standards and supports sustainability efforts, reducing waste.

Recycling Opportunities for Used Oil

Recycling used oil is easier with reliable oil skimming systems. Companies can recycle the skimmed oil, reducing environmental risks. This supports environmental regulations and can even generate extra income by turning waste into a resource. Automatic oil skimming helps industries be more sustainable and efficient.

For inquiries or to engage Freytech’s consultation services, clients can contact Freytech Inc. at +1 (305) 372-1104. The support team is ready to help with questions and guide clients toward effective wastewater management solutions.

Environmental Impact and Sustainability

Oil water separators are key in tackling big environmental issues. They help separate harmful hydrocarbons from water, reducing pollution. This leads to a big drop in oil contamination in wastewater, up to 90% in some cases.

This improvement helps meet strict rules and protects water life. It’s a big win for both the environment and businesses.

Reduction of Water Pollution

Oil skimmers make sure water is clean enough for industry standards. They help companies follow rules better, by about 70%. This means water can be much cleaner, with oil levels below 10 parts per million.

Promotion of Resource Recovery

Oil separators also help in using materials again, like recycled oil. Companies using new tech, like BOLLFILTER, see better use of resources. This is good for the planet and helps reduce the need for new oil.

Contribution to a Greener Future

As companies go green, oil separation systems play a big role. They help cut down on harmful emissions and make waste management safer. Using these systems shows a company cares about the planet.

It also helps them look good in the market. For more on oil water separation, check out Freytech.

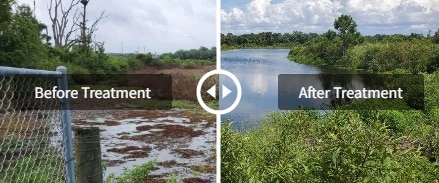

Case Studies and Success Stories

Oil water separators have helped many industries work better and follow environmental rules. Companies in these case studies show how Freytech’s products work well in managing wastewater.

Industries Benefiting from Oil Water Separators

Manufacturing, food processing, and textiles have seen big improvements. For example, manufacturing clients cut their water costs by 40% with custom solutions. Food processing moved towards zero discharge, showing Freytech’s technology is versatile.

Textile factories also used advanced systems to handle tough wastewater. This shows how Freytech’s solutions work for different industries.

Real-Life Applications of Freytech Products

Companies from different fields have used Freytech’s solutions. They saved money on wastewater disposal and avoided fines. They also saved on engine maintenance, showing Freytech’s oil water separators make a big difference.

Measurable Outcomes and Customer Feedback

Customers love Freytech’s technology. They say it’s worth the investment, with returns in 2-5 years. The systems cut down pollutants and improve water quality, showing clear benefits.

These stories prove Freytech’s solutions are effective in managing oil water. They encourage others to use these products.

Getting Started with Freytech Inc.

Freytech Inc. offers tailored solutions for wastewater management. Their Freytech consultation services help clients find the best custom oil water separator solutions. They assist with system selection and implementation strategies to ensure the best results.

Consultation and Custom Solutions

Interested clients can reach out for individual consultations. Freytech develops custom oil water separator solutions with high separation efficiency. Some models can purify fluids down to 0.1 PPM.

Their above-ground separators meet the CAN/ULC-S656 standard. This shows their commitment to quality and environmental compliance.

Contact Information and Support

For inquiries or to engage Freytech’s consultation services, clients can contact Freytech Inc. at +1 (305) 372-1104. The support team is ready to help with questions and guide clients toward effective wastewater management solutions.

Next Steps for Interested Clients

As industries focus on decarbonization, Freytech ensures its products meet strict standards. This includes compliance with the US EPA’s Clean Water Act. Clients looking to improve their environmental performance should explore Freytech’s solutions. They can help manage wastewater challenges while promoting sustainability.