How can a simple device change oily wastewater management into an efficient, green process? What Are The Advantages of Below Ground Separators? Below ground separators are systems that remove oil from water. They are key in many industries, from making things to washing cars. These systems save space and help meet strict rules, making them vital today.

Companies like Freytech Inc. use new tech to make these separators very effective. They can remove oil as small as 0.1 parts per million. This helps businesses follow the US EPA’s Clean Water Act rules.

Learning about advantages of below ground separators is more than just knowing how they work. It’s about protecting the environment, keeping people safe, and saving money over time. In this article, we’ll look closer at the benefits of underground separators and why they’re important in today’s world.

Key Takeaways

- Below ground separators effectively remove hydrocarbons, achieving separation efficiencies below 5 PPM.

- Freytech Inc. separators can target tiny oil particles, reaching separation levels as low as 0.1 PPM.

- These systems are compliant with North American environmental regulations, including the CAN/ULC-S656 standard.

- Industries such as manufacturing, gas stations, and car washes benefit significantly from these separators.

- Routine maintenance is key for top performance and following rules.

- Below ground separators handle big wastewater, with some for up to 1000 Imperial gallons per minute.

- Regular checks are needed to keep quality high and follow standards.

Introduction to Below Ground Separators

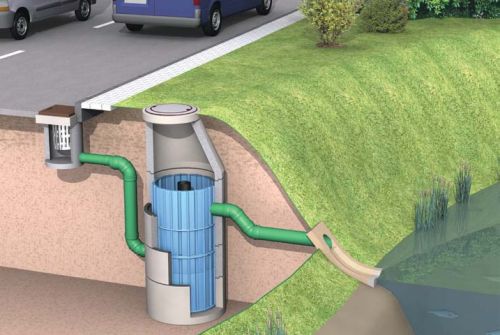

Below ground separators, also known as oil-water separators, are key in the industrial world. They remove oils and hydrocarbons from water. Knowing what they do shows why they’re important in many fields.

Definition and Purpose

These systems use different technologies to separate oil from water. They help meet environmental rules. This is vital for industries that deal with oily wastewater, like mining and car making.

Importance in Oil-Water Separation

Good oil-water separation keeps our environment safe and helps businesses run smoothly. Following environmental laws saves companies from big fines. It also cuts down on costs for water disposal.

Overview of Technologies Used

Below ground separators use various methods, like coalescing and centrifugal systems. Coalescing plate separators are great because they help oil droplets stick together. Centrifugal separators spin oily water fast to catch tiny oil droplets.

These technologies are key to effective separation. They work well in many industries. For more on these technologies, check out oil extraction solutions.

Enhanced Coalescing Technology Explained

Enhanced coalescing technology is a big step forward in oil-water separation. It uses special media to help oil droplets come together. This makes the separation process much more efficient.

Both free oil and emulsified hydrocarbons can be removed effectively. This is a key benefit of using below-grade separators.

How it Works

The process relies on coalescence, where small droplets grow into bigger ones. This makes the separation more efficient. The filters are built in layers to help this happen.

It’s important to place these filters correctly. They should be before sensitive equipment like compressors. This keeps the equipment clean.

Benefits of Enhanced Separation

One big advantage of below ground oil separators is their ability to clean water well. They can get water down to 0.1 PPM, which is much better than old methods. This helps meet strict quality standards.

It also makes gas processing operations last longer and work better. This is key for keeping gas clean and marketable.

Comparison to Traditional Methods

Old methods struggle with emulsified oils, leading to dirty water and more maintenance. Enhanced coalescing technology does much better. It removes both liquid droplets and solid particles.

Thanks to advanced filter media, these systems work more efficiently. They keep equipment clean and running well, avoiding damage from liquids.

Compliance with Hydrocarbon Discharge Limits

Following environmental rules on hydrocarbon discharge is key for North American industries. They must stick to strict standards, like a 10 PPM limit. Freytech Inc. separators are top-notch, reaching 5 PPM separation efficiency. This makes them a solid choice for meeting regulations.

The benefits of buried separators include seamless integration into current setups. They also keep water systems clean and free from pollution.

Understanding North American Standards

North America has strict rules for hydrocarbon discharges into water. These rules require industries to take steps to reduce harmful pollutants. Freytech’s separators help businesses meet these standards with their below ground designs.

Achieving 5 PPM Separation Efficiency

Freytech separators go beyond the 5 PPM efficiency mark. This high performance helps the environment and avoids fines for not following rules. It also supports long-term goals and keeps operations running smoothly.

Meeting Environmental Regulations

It’s vital for businesses to operate within the law. Below ground separators make it easier to follow environmental rules. They need little maintenance and are designed for efficiency.

Using these separators lets companies focus on their main tasks. They avoid the risk of fines, which can be very costly.

Performance Features of Freytech Inc. Separators

Freytech Inc. offers a variety of below ground separators. They are designed to manage different types of hydrocarbons. These systems are made to handle tough wastewater, ensuring top performance in treating oil-water mixtures.

Separation of Various Hydrocarbons

Freytech separators can handle hydrocarbons with specific gravity from 0.82 to 0.88. They separate motor oils, diesel, and gasoline very well. This means they can reduce oil levels in water to less than 5 PPM, even from levels as high as 2000 PPM.

This meets Canadian standards, like the CAN/ULC-S656. It shows they are reliable and follow rules for wastewater management.

Efficiency in Emulsified Oil Removal

Freytech separators are great at removing emulsified oil. This is key for meeting environmental rules. They can get oil levels down to 0.1 PPM, helping facilities meet strict discharge limits.

The technology used focuses on effective treatment. This ensures the water is safe, meeting all regulatory standards.

Reusability of Coalescing Media

The coalescing media in Freytech separators adds to their economic benefits. It can be reused, making maintenance easy. This cuts down on costs and extends the equipment’s life.

This feature highlights the value of subterranean separators. They offer a cost-effective solution that’s also sustainable.

The Role of Optional Patented Oil Skimmer

Freytech Inc. has a new solution with its optional patented oil skimmer. It works by sucking the oil out of the water and into a container. This makes collecting oil easier and more efficient.

Mechanism of Operation

The oil skimmer uses a mechanical process to collect oil. It can handle flows from 1 GPM to 100 GPM, fitting different needs. This makes it a key part of the system.

Advantages of Mechanical Drainage

This method saves money by making oil recovery more efficient. It cuts down on waste disposal costs. The skimmer also helps reduce sludge, which can extend the system’s life.

Purity Achievements in Separated Oil

The oil collected is very clean, with 99.7% free from water. This shows how good subsurface systems are. It means the oil can be recycled, saving money and helping the environment.

Economic Benefits of Using Below Ground Separators

Below ground separators bring big economic wins for businesses. They make operations more efficient, cutting down on costs for treating contaminated water. This means less waste to treat, leading to lower expenses.

Reduced Disposal Costs

The tech in below ground separators cuts down waste volume, saving a lot on disposal costs. They separate oil from water well, reducing hazardous waste. This lets companies save money and use it for other important areas.

Enhanced Recovery of Valuable Commodities

These separators use special techniques to get more oil from existing resources. This boosts revenue and shows the value of using them. Recovering and reusing valuable materials is smart for businesses.

Long-term Savings on Maintenance

Below ground separators also save money over time on upkeep. They need less maintenance than old systems, saving on labor and downtime. This leads to steady efficiency and financial gains, proving their worth.

Environmental Impact and Sustainability

Below ground separators are key to reducing the environmental impact of oil-water separators. They lower pollution in runoff and wastewater. This protects local waterways and helps ecosystems.

These systems prevent harm to aquatic life. This is vital for keeping biodiversity healthy.

Lowering Pollution Levels

Below ground separators keep contaminants out of natural water bodies. They use advanced technology to filter and separate harmful substances. This keeps water quality safe.

Industries can then operate more responsibly. They follow rules to protect our ecological resources.

Contribution to Local Ecosystems

These separators help ecosystems by preventing flooding and soil erosion. They slow down the release of treated water. This allows for sedimentation and pollutant reduction.

Healthier waterways support wildlife and community recreation. This makes ecosystems thrive.

Commitment to Green Technology

Freytech Inc. is dedicated to green technology. It uses sustainable practices in its designs. The company’s focus on high-density polyethylene construction reduces environmental impact.

This also cuts down on maintenance costs over time. By investing in new technology, industries can manage their environmental impact. This helps create a cleaner planet for the future.

Applications of Below Ground Separators

Below ground separators have many uses across different fields. They are great at improving water quality. Their main benefit is in separating oils from water, helping meet environmental rules and bettering water quality.

Industrial Uses

In places like oil depots and factories, these separators are key. They handle wastewater with oils and greases well. This helps in safe disposal and meeting strict rules.

Places using these separators see less legal trouble and follow rules better.

Commercial Deployments

Big shopping malls and parking lots use them to clean stormwater. This stops pollution from getting into rivers and lakes. It also makes people see these places as caring for the planet.

Municipal Water Treatment

Water treatment plants use them a lot. They clean runoff before it gets to nature. This cuts down on harmful stuff in water, keeping people healthy.

It shows how important these separators are for our health and the planet.

Installation and Maintenance Considerations

Getting below ground separators installed and maintained right is key for their best performance. Knowing how to install them properly helps them work well for a long time. The first step is a detailed site check. This helps spot any soil issues or hidden utility lines.

Following local laws is also important for safety and to avoid legal trouble.

Installation Process Overview

Installing underground separators involves a few important steps. First, a site survey is done to see what the ground is like. This includes looking at the soil and the environment. This helps predict any problems that might come up.

Getting the site ready right can avoid many issues and make the installation go smoothly.

Routine Maintenance Best Practices

Keeping underground separators in good shape is important. Regular cleaning stops clogs and keeps them working well. Checking the oil-water separation media is also key. This ensures it’s doing its job right.

Also, watching for solids buildup in the collection chamber is important. Regular checks help keep the separator working at its best.

Troubleshooting Common Issues

Knowing how to fix common problems can save a lot of time. Issues like blockages or not separating oil and water well can happen. Regular inspections help find these problems fast.

Fixing problems right away keeps the system running smoothly. It also makes the separator last longer. Knowing how to install and maintain these systems ensures they work well. This helps the environment and meets our goals.

Case Studies: Successful Implementations

Many industries have seen great success with oil-water separators from Freytech. These examples show how these separators work well in different fields. They improve how things work and help follow environmental rules.

Industries Benefiting from Freytech Separators

The car, manufacturing, and water management sectors have seen big benefits. These separators help keep emissions low and make more use of resources. This is good for the environment and for business.

Testimonials from Satisfied Clients

People who use these separators are very happy with them. They say their waste management gets better and they meet environmental standards. This makes their operations more successful.

Measurable Impact on Operations

Using oil-water separators makes things run smoother and cheaper. Places that use them work better and take care of the environment more. This meets today’s goals for being green.

Innovations in Separator Technology

The world of oil-water separation technology is changing fast. It’s all about making things more efficient and green. New technologies are making separators better and more eco-friendly, meeting the industry’s growing needs.

Future Trends in Oil-Water Separation

New trends are bringing advanced materials and methods to separator tech. With a focus on being green, nanotechnology and membrane filtration are leading the way. They aim to improve how well separators work, helping to meet stricter environmental rules.

Ongoing Research and Development

Research in separator tech is ongoing and strong. Many groups are working hard to find new materials and methods. Their goal is to create separators that not only meet today’s standards but also look ahead to the future.

They’re exploring new coatings and smart sensors to make things better. This work is key to improving how separators work and how they’re maintained.

The Role of Freytech in Advancing Technology

Freytech is leading the charge in these advancements. They’re always looking to improve their products. By investing in research and development, Freytech keeps their separators up to date with what the market needs.

They’re all about making things sustainable and effective. Freytech is playing a big role in shaping the future of oil-water separation technology.

Conclusion: Making the Right Choice

Below ground separators offer big benefits, mainly for industries under strict environmental rules. They improve separation, meet environmental standards, and save money. These systems are key for managing wastewater well.

They help cut down costs and protect local ecosystems from pollution. This is very important.

Recap of Advantages

Below ground separators handle many contaminants well. This means cleaner water for industries. It also helps avoid big fines for not following rules.

Freytech Inc. designs these systems to work better and last longer. This makes them a smart pick for wastewater treatment.

Why Choose Freytech Inc.?

Choosing Freytech Inc. means getting top-notch technology for better efficiency. Our systems are built to last, saving you money on repairs. This keeps your operations running smoothly.

If you have questions or need custom solutions, our team is here to help. We’re ready to assist you with your waste management needs.

Contact Information for Further Inquiries

Want to learn more about below ground separators and how Freytech Inc. can help? Call us at +1 (305) 372-1104. Our team is eager to guide you in choosing the right solution for your facility.