Is your business getting the most out of its oil recovery strategy? Or are valuable resources slipping away? With stricter environmental rules, knowing the Benefits of Adding an Oil Skimmer to an Oil Water Separator is key. It boosts efficiency, cuts down on contamination, and lowers costs.

Technologies like high-temperature oil skimmers work well in many industries. This includes steel making and food processing. It’s a big change for your business, both financially and for the environment.

Key Takeaways

- Oil skimmers enhance operational efficiency and production rates in parts washers.

- Regular oil removal extends the lifespan of parts washers, minimizing wear and tear.

- Implementing oil skimmers decreases maintenance and disposal costs by reducing the need for cleaning agents.

- Improved workplace safety is achieved by lowering risks associated with hazardous fluid handling.

- Aid in achieving compliance with environmental regulations and reduce the carbon footprint.

- High-temperature oil skimmers, like Zebra Skimmers, efficiently operate in various fluid temperatures.

Understanding Oil Water Separators and Their Function

Oil water separators are special devices that separate oil from water. They are key for keeping water clean in many industries. They help remove harmful substances from wastewater, making water safer.

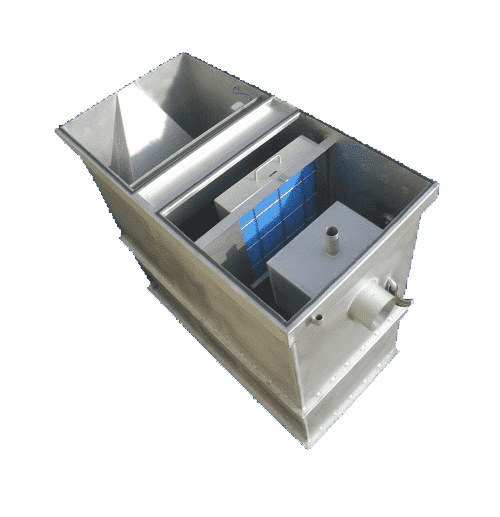

What is an Oil Water Separator?

An oil water separator is a tool used to clean wastewater by removing oils. It’s very important in places where oil can get into water, like factories. It helps keep water clean and avoids fines from environmental rules.

How Do Oil Water Separators Work?

These separators work by using gravity and coalescence. Oil droplets in the water rise to the top because they’re less dense. This makes it easy to collect and remove the oil.

Key Components of Oil Water Separators

Important parts of these separators include oleophilic media. It helps oil droplets stick together, making them easier to remove. They also have coalescing plates or filters for better separation. Keeping them well-maintained helps them work for over 20 years.

The Importance of Compliance with Hydrocarbon Discharge Limits

Following hydrocarbon discharge rules is key for industries handling oily water, like those in North Carolina. Here, strict rules are in place. Federal laws say discharges can’t have more than 10 parts per million (PPM) of hydrocarbons. This shows how important oil water separators are for meeting these rules.

Overview of North American Regulations

In North America, many rules control how industrial wastewater is treated. Places like car washes and industrial sites must use oil water separators. These systems stop big pollution problems by keeping soil and water clean.

Used motor oil can pollute a huge amount of fresh water. So, following environmental rules is very important.

The Role of Oil Water Separators in Compliance

Oil water separators are vital for industries to follow these strict limits. Thanks to technology from Freytech Inc., they can cut down hydrocarbons like motor oil and gasoline to 0.1 PPM. This meets federal rules and shows the benefits of oil water separators.

They can keep hydrocarbons at 5 PPM, helping businesses go beyond legal standards. This means less oil pollution and safer environments.

Enhancing Separation Efficiency with Oil Skimmers

Oil skimmers are key in making oil water separators work better. They remove floating oil, making the separation process smoother. This leads to cleaner water, meeting strict purity standards.

Companies that use these systems see big improvements. They can get rid of more oil in their water, staying within legal limits.

How Oil Skimmers Improve Performance

Oil skimmers make the start of treatment better, making systems last longer and work better. There are different types like belt, disk, and tube skimmers. Each one fits different needs, helping to get oil out efficiently.

Belt skimmers work well in hot places, and tube skimmers handle shallow sumps with changing water levels. They keep the water clean and safe.

Achieving Lower PPM with Enhanced Technology

New tech, like the Z17 Coalescer, helps remove oil all the time, even when the main pump is off. This makes the system even better at separating oil and water.

Skimmers also lower fire risks by getting rid of oil buildup. This stops problems in coolant lines, keeping things cool and lubricated. It saves money and meets environmental rules, showing how vital oil skimmers are today.

Advantages of Using Freytech Enhanced Coalescing OWS

Freytech Enhanced Coalescing Oil Water Separators have many benefits. Their design and technology are innovative. They use special coalescing media that grabs oil droplets, making them rise quickly to the top.

Unique Coalescing Media and Its Benefits

The coalescing media in Freytech separators is made to remove oil well. This means oil levels can drop to as low as 0.1 PPM. This meets or beats environmental rules, helping many industries stay compliant.

Reusability and Maintenance of Coalescing Media

The coalescing media can be washed and reused. This cuts down on maintenance costs. It also means less downtime and longer equipment life, boosting efficiency.

This approach to maintenance is good for the environment too. It helps businesses be more eco-friendly, making Freytech separators a smart choice.

Environmental Impact of Efficient Oil Separation

Efficient oil separation is key to environmental sustainability in many industries. Companies using oil skimmers see big benefits for the planet. These devices improve fluid quality and cut down on oil pollution.

Reducing Pollution with Better Oil Water Separation

Oil skimmers work well with traditional oil water separators to clean discharge. This stops polluted fluids from getting into waterways. It helps industries reduce their environmental impact.

Removing oils from coolants and processing fluids boosts production quality. It also protects our ecosystems.

The Importance of Recycling Used Oil

Recycling used oil is vital for reducing waste and supporting a circular economy. Facilities with tramp oil skimmers manage and recycle process fluids well. This includes sectors like chemical processing and automotive manufacturing.

Cleaned oils can be reused, reducing waste and improving safety. Recycling is a big part of ecological responsibility. It’s key for industries to stay compliant and work more efficiently.

The Economics of Implementing an Oil Skimmer

Using an oil skimmer can save industries a lot of money. It makes removing oil from wastewater cheaper and more efficient. This helps companies save on disposal costs and use less expensive cleaning products.

Cost Savings on Used Oil Disposal

Getting rid of used oil can cost a lot for businesses. Oil skimmers help by removing excess oil, which means less waste to dispose of. This leads to big savings in waste management costs.

Companies can use the money saved to do other important things. They can also keep up with environmental rules without breaking the bank.

Oil as a Valuable Recyclable Resource

Oil that’s recovered is not just a byproduct; it’s a valuable resource. Businesses can make money by selling it. This turns a waste product into a source of income.

By adding oil skimmers to their operations, companies can save money and help the environment. They show they care about sustainability.

Overall Benefits of Including an Oil Skimmer

Adding an oil skimmer to your operations brings many benefits. It makes your work more efficient and helps you follow environmental rules. These systems offer automatic and mechanical ways to remove oil, cutting down on manual work.

Thanks to new technology, these systems do more than old methods. They improve how things work a lot.

Automatic and Mechanical Oil Drainage

Today’s oil skimmers come with features like automatic shut-off timers. This makes them work better and safer. It also cuts down on waste by about 30%.

Using oil skimmers also means less damage to important fluids. This leads to less downtime and lower maintenance costs. In fact, breakdowns can drop by up to 30% when fluids are clean.

Achieving High Purity Levels (99.7% Pure Oil)

Oil skimmers can make oil very clean, up to 99.7% pure. This is great for keeping products high quality and meeting strict environmental rules. Clean fluids can also make products better by about 20%, making customers happier.

Also, using oil skimmers can cut down on hazardous waste by over 40%. This can save companies from big fines, which can be around $10,000 per violation. Overall, oil skimmers make operations more sustainable and efficient.

Case Studies of Successful Implementation

Many industries have seen big wins by adding oil skimmers to their work. They’ve boosted efficiency and helped the environment. Places like petrochemicals, shipping, wastewater treatment, and manufacturing have all benefited. They’ve tackled pollution and made oil recovery better.

Industries Benefiting from Oil Skimmers

The petrochemical and manufacturing fields have seen big gains. Oil recovery rates have jumped by up to 30% thanks to oil skimmers. Wastewater treatment plants have also cut costs by using oil skimmers and better separation tech.

Real-World Examples of Enhanced Efficiency

A shipping company had big oil spill problems, leading to high costs and downtime. They fixed this with a new system that included oil skimmers. This made oil much cleaner, from ISO 24/22/18 to ISO 16/14/11.

They also didn’t have to stop work for long. This shows how oil skimmers can make things better and protect the planet.

Getting Started with Freytech Solutions

Choosing the right oil water separator is key to getting the most from Freytech solutions. Several factors, like the type of oil and the volume of wastewater, play a role. Freytech offers customizable packages for various industrial needs, ensuring top performance in different settings.

How to Choose the Right Oil Water Separator

It’s important to understand the benefits of oil water separators. Companies need to consider their specific situation, such as the type of wastewater and discharge limits. Freytech’s separators can remove oil to less than 5 PPM, meeting North American standards.

They offer both below ground and above ground options. These can handle up to 1000 Imperial gallons of wastewater per minute. This makes them a great choice for removing oil cost-effectively.

Customizing Freytech Products for Your Needs

Freytech offers expert advice to tailor oil water separators to fit your needs. Their advanced technology can remove oil to less than 0.1 PPM. This meets EPA Clean Water Act standards.

Regular maintenance and inspections keep these systems reliable and long-lasting. This shows the value of using Freytech solutions in managing wastewater.

Contact Freytech for More Information

Freytech Inc. offers services and products to boost oil recovery and oil water separation. They use advanced tech to provide an effective oil removal system. If you’re interested in their oil skimmer benefits, reach out to their team.

Freytech Inc. Services and Products

Freytech is all about innovative solutions for better separation and meeting discharge rules. Their oil water separators can separate oil below 5 PPM, beating the North American limit of 10 PPM. This helps industries meet tough environmental standards while getting top-notch oil removal systems.

How to Reach Us: Phone and Support Information

Call +1 (305) 372-1104 for questions about Freytech’s products or to see how they can fit your needs. The team is eager to help. For more on their oil extraction solutions, check out Freytech’s website. Start your journey to better oil skimmer benefits today.

Conclusion: Invest in a Clean Future

As companies focus more on the environment, getting a good oil removal system is key. Using the latest tech like oil skimmers and separators makes oil separation better. This helps follow rules and supports a greener future.

The Long-Term Benefits of Effective Oil Water Separation

Knowing the good of oil water separation helps businesses run better and cleaner. It cuts down pollution and saves money on oil disposal. Plus, it helps recycle oil, showing a move towards using resources wisely.

With more people wanting seafood, keeping water clean is vital. It helps marine life and supports many industries.

Making an Informed Choice for Your Business

Choosing the right oil separation tech is smart for both your business and the planet. Getting the right oil water separator or skimmer means investing in a cleaner future. It shows you’re serious about running your business in a way that’s good for the environment.