Do you know What Industries Use Above Ground Oil Water Separators? or how important oil water separators are for keeping our environment clean? In today’s world, companies must handle waste well and follow strict rules. Above ground oil water separators help by taking out harmful substances from water. But which industries use them, and why are they becoming more popular? This article explores the many uses of oil water separators, showing their key role in keeping pollution under control and meeting North American standards.

Key Takeaways

- Above ground oil water separators are key for industries like oil refineries, chemical plants, and food processing.

- They help meet tough environmental rules by removing pollutants to less than 10 PPM.

- Many industries need custom solutions for effective pollution management.

- New technologies improve the oil/water separation, making water cleaner.

- It’s important to keep separators in good shape through regular checks.

- These systems make work easier and help avoid big fines for pollution.

- Oil water separators are also critical for managing stormwater runoff, following the US EPA’s Clean Water Act.

Introduction to Oil Water Separators

Oil water separators are key in managing wastewater, mainly in industries with oily water mixtures. They are designed to separate oil from water, helping treat contaminated wastewater. This process is vital for keeping industries in line with regulations and protecting the environment.

Definition and Purpose

Oil water separators are made to treat wastewater and lessen environmental harm. They separate oil and water, removing pollutants safely. This is critical in industries like oil and gas, automotive, and manufacturing for effective wastewater treatment.

Importance of Clean Water Discharge

Clean water discharge is very important. Industries can face big fines for not disposing of contaminated water properly. Oil water separators help meet local regulations, promoting sustainability and protecting the environment. They play a big role in keeping water resources safe and reducing pollution.

Industries That Benefit from Oil Water Separators

Many sectors use oil water separators for effective wastewater treatment. Each industry has its own challenges with oil and water separation. These systems are key for efficiency and following rules.

Oil and Gas Industry

The oil and gas industry is a big user of oil water separators. These systems help manage oily wastewater from extraction and refining. They cut down on waste disposal costs, which can be very high.

Manufacturing Industry

In manufacturing, oil water separators prevent water pollution. They keep oil out of water, protecting equipment and saving money. Companies can save 30% to 50% on maintenance costs.

Transportation Sector

The transportation sector uses oil water separators for vehicle maintenance and washing. It’s important for following EPA rules. Using these systems helps avoid big fines.

Marine and Shipping Industry

In the marine and shipping world, oil water separators are vital. They improve water quality after treatment. This helps meet environmental standards and promotes sustainability.

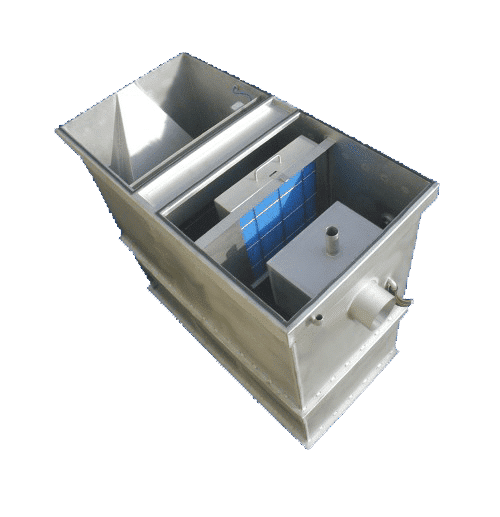

How Above Ground Oil Water Separators Work

Oil water separators are key in many industries. They work by using the difference in density between oil and water. This lets oil float up and water sink, making separation easy.

Basic Principles of Separation

These separators use gravity to sort wastewater. They come in different types for different needs. For example, gravity separators work well for low oil levels.

Places like factories use them to meet environmental rules. Car repair shops also use them to clean oil and grease from water. This keeps the water clean.

Enhanced Coalescing Technology

New technologies make oil water separators better. They help oil droplets combine, making them easier to remove. This is important for places with a lot of pollution.

Coalescing plate and centrifugal separators are great for this. They work well in places like airplane maintenance, where pollution is a big risk. This technology helps keep the environment safe.

In the sea, these separators are vital for cleaning bilge water. They stop pollutants from harming the ocean. Keeping them clean is important for their effectiveness. This shows how important oil water separators are for keeping our water clean and safe.

Compliance with Regulatory Standards

Regulatory standards are key to managing oil water separators well. They make sure industries follow safe water discharge practices. It’s important to follow North American discharge limits to avoid polluting the environment.

These limits say that hydrocarbon levels in treated water should be under 10 Parts per Million (PPM). This shows how vital it is to follow rules for wastewater treatment.

North American Hydrocarbon Discharge Limits

North America has strict rules for hydrocarbon levels in wastewater. Companies need the right technology, like oil water separators, to meet these standards. Not following these rules can lead to big fines and harm a company’s finances and image.

Businesses in oil and gas, manufacturing, and marine sectors are watched closely. They must have strong oil water separator compliance plans in place.

Importance of Meeting 10 PPM Standards

Keeping to the 10 PPM standards is essential for protecting the environment. Companies that meet these standards show they care about waste management. By using good systems, they can greatly reduce hydrocarbon levels in water.

This not only keeps water safe but also avoids legal trouble. Being proactive helps a company’s image as an eco-friendly business. Today, using advanced oil water separators shows a company’s dedication to sustainability and following the law.

Freytech Inc.’s Separation Efficiency

Freytech Inc. is dedicated to top-notch oil water treatment. Their advanced technology can separate oil from water as low as 5 PPM. This helps industries meet and exceed environmental rules.

Achieving 5 PPM with Advanced Technology

Freytech uses the latest techniques for oil and water separation. Their systems can reach a separation efficiency of 5 PPM. This is key for industries with strict rules, ensuring clean discharges for the environment.

The Role of Coalescing Media

Coalescing media plays a big role in Freytech’s success. It helps merge small oil droplets into bigger ones for easier separation. The mixture gets enough time to settle, making the separation process more efficient. This shows Freytech’s leadership in the market.

Managing Emulsified Oil

Emulsified oil is a big challenge in wastewater treatment, mainly for industries with strict rules. It’s key to manage emulsified oil well to follow rules and protect the environment. Freytech uses advanced tech to separate tiny amounts of oil from water.

Separation of Trace Amounts of Oil

Most systems aim to remove free oil, but emulsified oil needs special methods. Freytech’s separators are made to handle this, getting rid of oil down to very low levels. This helps facilities meet rules and lessen harm to the environment.

Efficiency of 0.1 PPM Separation

Freytech leads in oil separation, reaching levels as low as 0.1 PPM. This is vital for plants dealing with oil in water and strict standards. High-efficiency systems help follow rules and support green practices by recycling water.

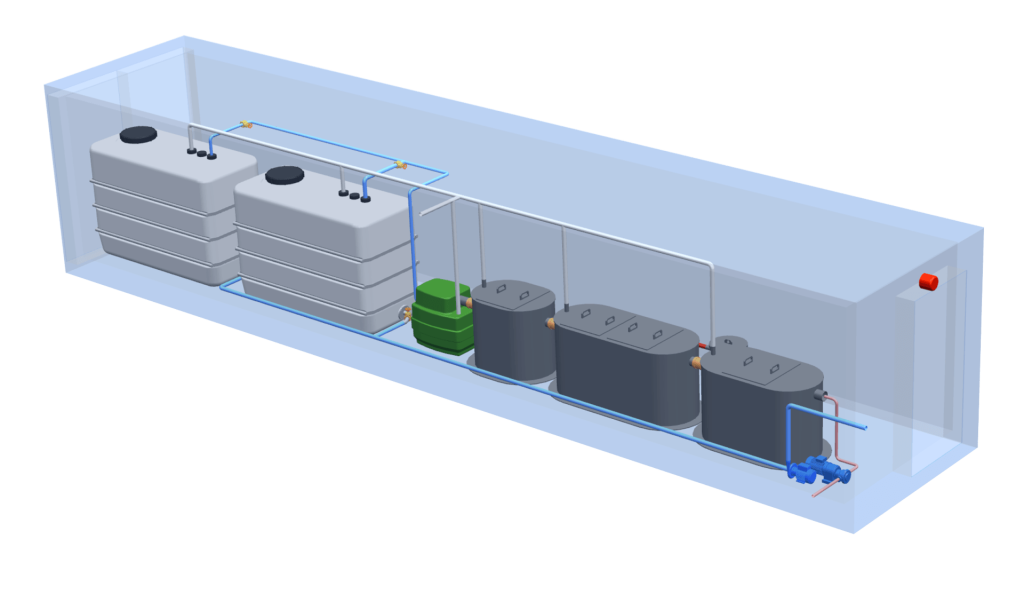

Benefits of Freytech Separator Packages

Freytech separator packages bring big benefits. They make operations more efficient and help the environment. A key feature is the reusable coalescing media. This means longer life and easier upkeep, making them cost-effective.

Reusability of Coalescing Media

Freytech’s separators are designed for easy maintenance. This leads to a longer life and steady performance. Using reusable media, Freytech separators cut down on replacement costs and needs.

Long-term Cost Effectiveness

Freytech systems save money on wastewater management. They achieve high separation efficiencies, saving resources. This lets businesses spend their money wisely. Freytech separators also help meet strict environmental rules without breaking the bank.

Skimming and Recycling Used Oil

Efficient skimming and recycling are key to managing used oil. They help keep our environment clean. Freytech’s patented oil skimmer is a top choice in the industry. It removes oil from water effectively, leaving water almost pure.

Functionality of the Patented Oil Skimmer

The patented oil skimmer is very good at getting used oil back. It uses an automated system to recover oil efficiently. This means less downtime and more work done, saving time and money.

It also makes coolants last longer. This cuts down on the need to replace coolants often. It can save up to 50% on coolant costs.

Recycling as an Eco-Friendly Practice

Recycling used oil is good for the planet. It turns used oil into something useful again. This helps industries be more sustainable.

It also saves money on fines and waste disposal. Companies can follow rules and help the environment. This makes the world a cleaner place for the future.

Case Studies of Industries Using Freytech Solutions

Freytech has made a big difference in many sectors. They offer oil water separators for different industrial needs. These solutions help businesses meet environmental rules and promote green practices. They also make operations more efficient.

Real-World Applications

Many industries have seen the benefits of oil water separators. For example, oil and gas companies use them to handle wastewater. These separators remove hydrocarbons to less than 5 PPM, meeting Clean Water Act standards.

In manufacturing, companies have improved their wastewater management. This leads to cleaner water and less harm to the environment.

Success Stories

There are many success stories from using Freytech solutions. A steel factory saved a lot of money and met North American discharge limits. They used above-ground oil water separators to boost efficiency and follow local rules.

Their use of coalescing technology helped manage oil levels. This reduced the load on treatment equipment.

Conclusion

Above ground oil water separators are key in many fields like marine, automotive, and industrial. They save money, follow environmental rules, and make operations better.

Summary of Benefits

Using these separators can cut down on wastewater treatment costs. Keeping them in good shape is important for the best results. They work well with big oil problems, helping protect the environment.

They help companies meet environmental laws. This is good for both the planet and businesses.

Encouragement to Contact Freytech Inc.

If you need solutions for oil water separators, contact Freytech. They offer advanced tech that meets standards like MARPOL. This protects the environment and helps your business goals.

Get in touch with Freytech to see how they can help your business.

Contact Information

If you’re looking into advanced oil water separator solutions, Freytech Inc. is here to help. They focus on effective wastewater management. This ensures industries meet standards while improving efficiency. To learn more about their technology for your needs, contact the experts at Freytech.

Reach Out to Freytech Inc.

For more details or help, feel free to contact Freytech for oil water solutions. Their team is ready to offer insights specific to your industry. They aim to provide you with the best solutions.

Phone Number: +1 (305) 372-1104

Call Freytech at the given number for direct contact. Their support system is designed to help you choose the right options. They’re ready to answer all your questions about their services and products.