Ever thought about How to Choose the Best Oil Water Separator for My Needs? or how a simple piece of equipment can save your business from big problems? Picking the right oil water separator is key for industries with oily wastewater. The wrong choice can cause big issues and cost you a lot.

In this guide, we’ll look at what you need to think about when picking an oil water separator. We’ll cover the types available, flow rates, and environmental rules. Our goal is to help you make a smart choice. We’ll also talk about new tech that can make managing oil better.

For more info on different separators and how they work, check out this resource.

Key Takeaways

- Know what your industry needs in an oil water separator.

- Keep your oil water system in good shape with regular checks.

- Look at how well different separators work to protect the environment.

- Find the right type of oil water separator for your situation.

- Follow the rules to avoid fines and stay compliant.

- See how new tech can improve oil separation.

- Get advice from experts for solutions that fit your needs.

Understanding Oil Water Separators and Their Importance

Oil water separators are key in managing oil pollution in many industries. They remove oil, grease, and hydrocarbons from wastewater. This keeps harmful substances out of our natural water bodies.

What Is an Oil Water Separator?

An oil water separator is a device that separates oil from water. It’s vital in industries that use a lot of water mixed with oil. These systems use gravity, coalescing, or centrifugal techniques to remove contaminants.

Why Are They Necessary?

Oil water separators are needed because of strict environmental laws. These laws protect our water sources. Not following these laws can result in big fines and legal issues for companies.

They also help keep our water clean by removing small oil droplets. Using reliable oil water separators helps avoid environmental harm and keeps companies in line with the law.

Applications of Oil Water Separators

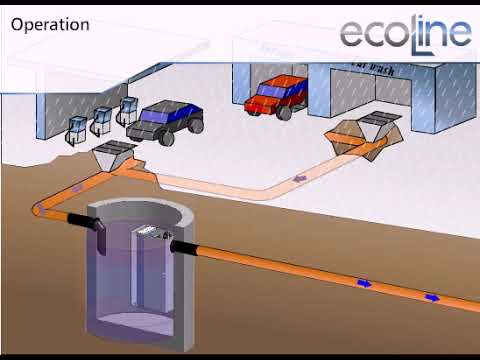

Oil water separators have many uses across different industries. Car washes and auto services use them to clean water before it goes into the city’s system. Industrial wastewater treatment plants also depend on them to manage oily wastewater.

Oil recovery from stormwater runoff is another important use. It helps fight pollution. Each use shows how important oil water separators are for keeping our environment safe.

Key Factors to Consider When Choosing an Oil Water Separator

Choosing the right oil water separator is important. You need to think about several key things to make sure it works well and follows the rules. Knowing how much flow you need is key to avoid problems.

Flow Rate Requirements

Flow rate is about how much liquid the separator can handle. Picking the right size is important to avoid blockages and keep things running smoothly. If it’s too small, it can cause big problems. If it’s too big, it can lead to high costs.

Separation Efficiency Ratings

How well the separator can remove oil is also important. Look for ones that can get oil levels below 10 PPM. These are top choices because they meet high standards. They help keep the environment clean and work well.

Environmental Compliance Requirements

Following environmental rules is a big deal. The right separator must meet local and federal laws. This is important to avoid big fines and protect the environment. A good separator not only follows the law but also helps take care of our planet.

Types of Oil Water Separators

It’s important to know about the different oil water separators to manage contaminants well. Each type has special features for various needs and budgets. Choosing the right one means looking at how well it works, how easy it is to maintain, and its effectiveness in separating oil and water.

Gravity Oil Water Separators

Gravity oil water separators use buoyancy to separate oil from water. They are very common. These units can handle big contaminants but struggle with tiny oil droplets. They work because oil is less dense than water, letting oil float to the top for removal.

This simple method makes gravity separators a budget-friendly choice for many uses.

Coalescing Oil Water Separators

Coalescing separators use special media to merge small oil droplets into bigger ones. This makes them great for meeting strict environmental rules. They are chosen for their high efficiency in reducing oil in wastewater.

Membrane Separators

Membrane separators use filters to achieve high separation efficiency. They can remove contaminants very well. But, they need more upkeep than gravity and coalescing separators.

When comparing oil water separators, consider the complexity of membrane separators. Make sure they meet your application’s needs for the best performance and reliability.

Specific Needs for Hydrocarbon Separation

Choosing the right oil water separator depends on knowing what hydrocarbon separation needs are. Different hydrocarbons like diesel, motor oil, and jet fuel need special separation methods. Freytech’s advanced coalescing separators are great at handling these needs, making sure all kinds of hydrocarbons are dealt with well.

Different Hydrocarbon Types

Hydrocarbons vary a lot, affecting the technology needed. For example, lighter oils might be easier to separate than heavier ones. Picking a separator that works well with different types of hydrocarbons helps a lot in treating wastewater. This can also lower costs for managing waste.

North American Discharge Limits

Following North American discharge limits is key for protecting the environment. The U.S. EPA sets limits, usually below 15 mg/L for oil in treated water. Freytech’s advanced systems can even get levels down to 5 PPM, meeting strict rules.

Importance of Separation Efficiency

How well a separator works is very important. Old gravity-based separators might only get 90% efficient, but new tech can hit over 99%. Choosing a separator with high efficiency is critical for following rules and keeping operations profitable. Knowing this helps industries pick the best separator for their needs.

Advantages of Freytech Enhanced Coalescing OWS

Freytech enhanced coalescing oil water separators are known for their high efficiency. They can discharge at 5 PPM, unlike the 10 PPM of standard units. This means cleaner wastewater, which is key for industries aiming to reduce environmental harm.

5 PPM vs. 10 PPM Discharge Efficiency

Freytech systems can discharge at 5 PPM, a big plus for industries with strict standards. This low oil level helps companies meet environmental rules and improve their green efforts.

Ability to Separate Trace Amounts of Oil

Freytech enhanced coalescing OWS can handle even tiny oil amounts. This skill is vital for managing oil in water well. It leads to cleaner water and keeps the treatment system working well.

Reusable Coalescing Media Benefits

Freytech systems use reusable coalescing media, which saves money. This media is easy to clean and lasts long, making maintenance less often. Its long life adds to the cost savings, making Freytech a top choice.

The Role of Oil Skimmers in Separation Systems

Oil skimmers are key in managing oil on water surfaces. They use mechanical methods to boost the efficiency of oil water separators. By pulling out free-floating oil, they help recover more oil and make recycling easier.

What Is an Oil Skimmer?

An oil skimmer is a machine that removes oil from water’s surface. It uses different technologies for different needs. Modern designs, like tube and disc skimmers, work well in many places.

They can handle rough waters and industrial settings. This makes them very flexible and effective.

Benefits of Including an Oil Skimmer

Oil skimmers do more than just remove oil. They help meet environmental rules by catching petroleum and other contaminants. This makes them useful in many industries.

They improve efficiency and avoid fines for environmental breaches.

Efficiency of Skimming Process

The skimming process’s success depends on the oil type. Good skimmers can remove a lot of oil, but sometimes need to go through it multiple times. In big spill responses, skimmers are vital with booms to get a lot of oil back.

Maintenance Needs for Oil Water Separators

Regular maintenance is key for oil water separators to work well and last long. A set maintenance schedule stops problems and keeps standards high. It’s important to check oil and water levels, look for leaks, and make sure everything works right.

Routine Maintenance Practices

Do routine checks every month to spot wear or damage. Also, change filters every 250-500 hours, based on how much you use it and the environment. Checking it every two weeks helps find issues early and keeps it running longer.

Cleaning and Reusing Coalescing Media

Cleaning the coalescing media is a big part of upkeep. Keeping it clean saves money and keeps the separator working well. The right cleaning methods make it last longer and help the environment by reusing parts.

Troubleshooting Common Issues

Knowing how to fix common problems is important. Regular checks can find issues before they get worse. Fixing problems early keeps the separator running smoothly and meets strict environmental rules.

Cost Considerations

When looking at oil water separators, it’s key to understand the costs. The initial cost versus long-term savings is a big factor. Many overlook the savings from less maintenance and better efficiency.

Initial Investment vs. Long-Term Savings

The cost of an oil water separator varies by brand and model. A high-quality unit might seem pricey at first. But, the savings over time can make it worth it.

Good systems last longer and need less maintenance. This means less money spent on replacements and upkeep. Knowing these benefits helps make better choices.

Cost-Effective Recycling of Separated Oil

Recycling the oil from separators can save money. It turns waste into something valuable. This can even make money for facilities.

By doing this, businesses help the environment and save money. It’s a win-win for both the planet and the wallet.

Comparing Brands and Models

When comparing oil water separators, look at performance, reputation, and warranties. Check out features and specs to find the best match. Some brands offer longer warranties and better service.

Reading reviews and ratings helps understand reliability and effectiveness. This helps make a smart choice. For more info, visit Freytech’s oil water separators.

Regulations and Compliance Guidelines

Understanding regulations for oil water separators is key for businesses. Knowing local and federal laws helps facilities stay legal and manage wastewater well. Not following these rules can cause big fines and harm a company’s image.

Understanding Local and Federal Regulations

Facilities need to stay updated on rules for discharging pollutants. The EPA is now focusing more on things like PFAS. Oil water separators can help meet these standards, avoiding fines of $25,000 to $100,000.

How Freytech Supports Compliance

Freytech Inc. helps make sure oil water separators meet legal needs. They guide companies in setting up systems that treat wastewater well. This way, businesses can lower environmental risks and work more efficiently.

Documentation and Reporting Requirements

Keeping up with documentation and reporting is vital for staying compliant. This means having detailed records of oil water separator maintenance. Working with Freytech helps businesses meet these reporting standards, keeping operations strong and accountable.

Getting Expert Guidance and Support

Choosing the right oil water separator is easier with expert help. Professionals offer insights that fit your specific needs and follow the rules. They also suggest ways to make your system work better and more reliably.

Why It’s Important to Consult Experts

Experts know a lot about different oil water separators and the rules they must follow. They help you pick the best system and explain how to keep it running smoothly. This avoids big problems and makes sure your place is safe for the environment.

Contacting Freytech Inc. for Assistance

If you need help, Freytech is a great place to start. Their team is ready to answer your questions and find solutions just for you. Call +1 (305) 372-1104 to talk about your options and get expert advice.