Ever wondered How to Choose the Right Oil Skimmer? or why some places save a lot on coolant while others spend too much? It’s often because of their oil skimmer choice. Oil skimmers are key in coolant systems, helping with efficiency and following environmental rules. We’ll show you how to pick the best oil skimmer. You’ll get tips and guides to help you make a smart choice.

Key Takeaways

- Oil skimmers can extend coolant life by up to 50%, leading to significant cost reductions.

- Implementing effective oil skimming can lower maintenance labor needs by up to 20%.

- Higher productivity is achievable when coolant quality is consistently managed.

- Careful selection of oil skimmers ensures compliance with environmental regulations, avoiding hefty fines.

- Understanding the specific needs of your facility is essential for maximizing oil removal efficiency.

Understanding Oil Skimmers and Their Purpose

Oil skimmers are key to keeping water systems clean. They remove oil, grease, and other pollutants. This helps industries run smoothly and meet environmental rules. Knowing how they work and their benefits is important.

What is an Oil Skimmer?

An oil skimmer is a device that pulls oil off water surfaces. It’s vital for handling oil spills and keeping coolant systems and waste treatment clean. There are different types, like belt, disc, and sponge skimmers, for various settings.

Benefits of Using Oil Skimmers

Oil skimmers do more than just remove oil. They also cut down on health risks from bacteria in oil. This makes workplaces safer. They also make coolants work better, saving money and extending machine life.

Using skimmers automatically means less manual cleaning. This cuts down on downtime, saving money and keeping operations running smoothly.

Common Applications of Oil Skimmers

Oil skimmers are used in many fields, like manufacturing, food processing, and petrochemicals. They help remove oil from cooling systems, saving money and improving product quality. Their effectiveness keeps systems running well, leading to a cleaner environment and meeting rules.

Types of Oil Skimmers Available

It’s important to know the different types of oil skimmers for managing oil in various settings. The market has mechanical, vacuum, and absorption oil skimmers. Each type is designed for specific needs and efficiencies.

Mechanical Oil Skimmers

Mechanical oil skimmers are great for separating oil from water and coolant. They use skimming disks or belts to collect floating oil. These skimmers are good at removing emulsified oils, making them a top choice for regular oil contamination.

But, their performance can change based on how the fluid levels move. It’s key that the skimming disk stays under water to work best.

Vacuum Oil Skimmers

Vacuum oil skimmers pull oil from under the water’s surface. They work well in places where oil is hard to remove because of surface tension. Vacuum skimmers are fast at removing oil from large tanks.

When setting up these units, it’s important to think about the tube path and mounting points. Their flexibility makes them great for managing metalworking fluids.

Absorption Oil Skimmers

Absorption oil skimmers soak up oil right away. They’re best for places with low oil levels, as they handle small amounts well. Absorption skimmers might not remove as much oil as others, but they’re essential in controlling oil where it’s not much.

Choosing the right absorption skimmer depends on the fluid’s condition and the specific situation. It’s all about finding the right fit for your needs.

Key Factors in Selecting an Oil Skimmer

Choosing the right oil skimmer is important. You need to know what your operation needs for the best results. Look at the type and quality of oil, the environment, and water flow.

Oil Type and Quality

It’s key to know what kind of oil you’re dealing with. Whether it’s light oils like machine coolant or thick oils like bunker fuel, the right skimmer matters. Skimmers for thick oils need to be stronger to handle more oil and help manage waste better.

Application Environment

The place where you’ll use the oil skimmer is also important. Industrial settings can be tough, with changing temperatures and oil levels. Skimmers made of stainless steel can handle high heat, making them good for tough jobs. Make sure the skimmer fits with your system to avoid problems and improve efficiency.

Water Flow Characteristics

Water flow is key for an oil skimmer’s performance. Look at flow rates and patterns to see what you need. Skimmers for high-flow areas can remove a lot of oil, which is important for big places. Choosing the right skimmer ensures oil is caught and removed, reducing contamination risks.

Evaluating Separation Efficiency

Separation efficiency is key when checking how well an oil skimmer works. It’s measured in parts per million (PPM), showing how much oil is left in the water. Low PPM values are important, as they meet North American standards of 10 PPM.

Technologies like enhanced coalescing can even lower PPM levels. They can reach as low as 0.1 PPM. This makes the water cleaner and helps follow environmental rules.

Understanding PPM and Its Importance

PPM is very important for oil skimmer ratings. A lower PPM means the skimmer is doing a great job. It shows how well it removes oil from water.

For industries using oil skimmers, keeping an eye on PPM is vital. It helps them stay in line with environmental rules. Knowing PPM levels helps make better choices when picking or upgrading equipment.

Features of Enhanced Coalescing Technology

Enhanced coalescing technology brings many benefits. It helps separate oil droplets better, making them easier to remove. Features like adjustable skimming depths and real-time monitoring systems help keep efficiency high.

Using oil skimmers with this technology can greatly improve oil removal. This can also cut down on maintenance and disposal costs.

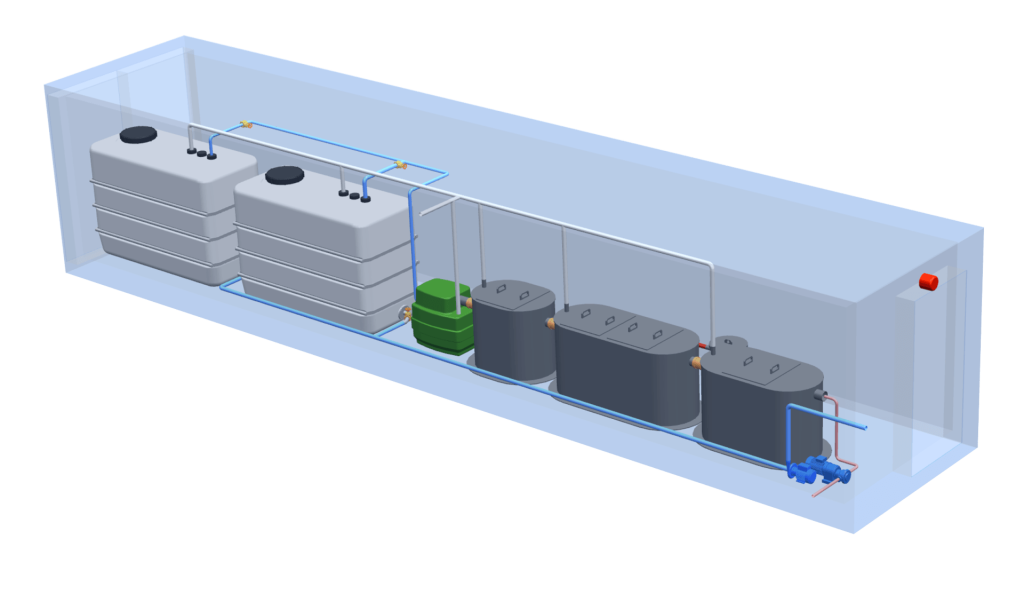

Freytech Inc. Oil Skimmer Solutions

Freytech Inc. leads in advanced oil skimming technology. They offer solutions for efficient oil recovery and waste management. Their systems use enhanced coalescing technology for better separation.

Freytech oil skimmers ensure a cleaner discharge. They achieve a separation efficiency of 5 PPM. This meets North American hydrocarbon discharge limits.

Overview of Freytech’s Technology

Freytech’s oil skimmers use advanced technology for oil-water separation. They can handle flow rates from 25 to over 640 gallons per minute (GPM). This makes them suitable for various industrial needs.

Their oil-water separators work reliably. They achieve levels below 5 PPM for free non-emulsified oils. They also manage hydrocarbons with specific gravity between 0.82 and 0.88.

Advantages of Freytech’s Enhanced Coalescing OWS

Freytech technology offers high performance and low maintenance. The systems separate trace amounts of emulsified oil. They achieve remarkable clarity, with 99.7% pure skimmed oil free of water.

This efficiency means no need for costly septic truck services. It reduces operational costs and environmental liabilities.

Reusability and Maintenance of Freytech’s Coalescing Media

Freytech’s coalescing media is reusable. It can be easily cleaned and sprayed washed. This promotes sustainability and offers long-term cost savings.

This focus on reusability makes Freytech a leader in environmentally responsible oil skimmer solutions.

Regulatory Compliance and Standards

It’s key for businesses to know the rules about oil discharge. They must follow strict environmental laws. This includes the North American hydrocarbon limits, which are 10 PPM for discharges. Following these rules protects the environment and keeps companies out of trouble.

Understanding North American Hydrocarbon Discharge Limits

The North American hydrocarbon discharge limits are a key rule for industries. They make sure oil is removed from water safely and effectively. Oil skimmers are important here. They help remove oil layers, keeping facilities in line with safety and environmental standards.

Importance of Separation Efficiency in Compliance

For companies to follow the rules, oil skimmers must work well. High separation efficiency helps meet or beat the North American hydrocarbon limits. This way, companies can avoid oil contamination risks. It also helps them follow environmental laws better.

Oil skimmers are a cost-effective way to manage waste. They help companies stay in line with rules and work efficiently.

Cost-Effectiveness of Oil Skimmers

Oil skimmers are key in today’s industries. They help save money by efficiently removing oil. This prevents oil buildup, which can harm equipment and shorten coolant life.

Savings through Efficient Oil Recovery

Oil skimmers can save a lot of money. For example, belt skimmers are great for small to medium-sized sumps. They are an affordable way to remove oil.

Disk and tube skimmers are perfect for small spaces. They collect oil well without taking up too much room. In places with lots of oil, you need skimmers that can handle it.

Environmental Impact and Sustainability

Oil skimmers also help the environment. They remove oil without using harmful chemicals. This reduces pollution and saves money on fines.

Using oil skimmers saves on waste disposal costs. It also helps recycle more. Companies that use them show they care about the planet. This is very important today.

Installation Requirements for Oil Skimmers

When planning to install an oil skimmer, knowing the specific needs is key. Each skimmer type has its own space and power needs. You must also consider the physical environment and tank access for efficient operation and maintenance.

Space Considerations

Space needs vary with the skimmer design. Belt skimmers need to be long to stay submerged at low fluid levels. Tube skimmers, on the other hand, are great for small sumps and use less space.

They are perfect for areas with shallow fluid levels. Disk skimmers also need the right spot, as the disk must stay underwater to work well. Choosing the right model means looking at available space, maintenance access, and fluid level changes.

Power and Utility Needs

The power needs of oil skimmers depend on the model. Some, like coalescers, need special power for handling oils and small particles. It’s important to have the right connections for electricity and water.

Adding equipment like coolant mixers and fluid monitors can boost efficiency and avoid downtime. Checking utility needs helps your skimmer run smoothly and last longer.

Maintenance Best Practices for Oil Skimmers

Keeping oil skimmers in good shape is key to their long-term performance. Regular checks and cleanings spot problems early. This not only boosts system efficiency but also meets environmental rules.

Regular Inspection and Cleaning

Regular checks on oil skimmers ensure they work well. Cleaning them often stops debris buildup. This keeps them moving smoothly and effectively.

For example, disk skimmers must stay in the fluid to work right. Regular maintenance stops costly breakdowns in industrial settings. It also makes oil removal more efficient, helping the environment.

Troubleshooting Common Issues

Knowing how to fix oil skimmer problems quickly is important. Issues like blockages or poor oil collection can happen. For example, tube skimmers work best in small sumps and shallow fluid.

Spotting these problems early keeps things running smoothly. It also makes the equipment last longer. Fixing issues fast saves money and keeps operations going without a hitch.

Benefits of Choosing Freytech Inc.

Choosing Freytech Inc. for oil skimming solutions offers many advantages. These benefits improve performance and reliability. Customers see their operations become more efficient and costs lower.

Performance Guarantees

Freytech’s quality is shown through its performance guarantees. These guarantees give customers peace of mind. They know the oil skimmers will work well, lasting longer and needing less maintenance.

These systems also prevent harmful buildup in cooling fluids. This stops corrosion and keeps machines working well. Plus, they help improve productivity and cut down on cleaning time.

Trusted Reputation in the Industry

Freytech’s strong reputation in the industry is a big draw. It’s known for its innovative tech and top-notch customer service. This sets it apart from others.

Its history of helping industries work better, follow environmental rules, and keep workers safe is key. Choosing Freytech means partnering with a trusted name for sustainable and effective oil skimming solutions.

Customer Support and Resources

Freytech Inc. focuses on top-notch customer support to help clients smoothly. You can call Freytech customer support at +1 (305) 372-1104 for personalized help. This line connects you with experts who know a lot about oil skimmers and can give detailed product information.

Contacting Freytech Inc.

It’s easy to get in touch with Freytech Inc. through different ways. You can email them or use online support forms. This makes it simple for customers to ask questions and get help. Freytech’s team is ready to help you understand your oil skimmer options and how to use them.

Additional Resources and Documentation

Freytech also provides a lot of resources for oil skimmers, including detailed documents. These resources cover product details, troubleshooting tips, and how to use them best. You can check out these valuable materials to learn more about oil skimmers. This helps make sure your operations are efficient and follow industry rules.

Final Considerations for Oil Skimmer Selection

Choosing the right oil skimmer can be easier with expert advice. Professionals offer insights that match your needs, oil types, and environmental issues. Their advice helps pick oil skimmers that meet your efficiency and maintenance needs.

Getting Expert Advice

Experts can help you understand key factors like size and oil viscosity. For example, small shops need different equipment than big refineries. They also consider temperature and maintenance needs for a better choice.

Making an Informed Decision

The main aim is to boost efficiency and save money in the long run. It’s a balance between upfront costs and long-term savings. With expert advice, you can make a better choice and keep your systems running smoothly.