Have you ever thought about What is the Efficiency of a Standard Oil Water Separator? or how well your facility handles wastewater? In today’s world, it’s key to know how well an oil water separator (OWS) works. This piece will explore the efficiency of these devices, which are vital for cleaning wastewater.

These devices help remove oil, grease, and other harmful substances from water. Meeting environmental rules depends on how well they work. You’ll learn about the importance of keeping hydrocarbon levels below 10 PPM and how new tech is improving efficiency.

Key Takeaways

- The standard efficiency of an oil water separator is critical for meeting regulatory compliance.

- The influent oil concentration for testing often starts at 1,000 ppm.

- U.S. EPA regulations set a discharge limit of less than 10 ppm for hydrocarbons.

- Advanced technologies can achieve separation efficiencies as low as 5 PPM.

- Non-compliance with discharge standards can lead to fines for facility operators.

- Performance standards for separators have been outlined and standardized November 2022.

Understanding Oil Water Separators

An oil water separator is a key tool that removes oil from water. It works by using the difference in specific gravity. Lighter oil floats to the top, while heavier stuff settles at the bottom.

This method helps get rid of hydrocarbons in water. It makes sure we follow environmental rules.

Definition and Function

An oil water separator treats wastewater with oil in it. It’s used in many places like oil and gas, marine, and manufacturing. It’s important for keeping our waterways clean.

By separating oil from water, it helps protect our environment. It also makes sure we follow the law about managing wastewater.

Application Areas

Oil water separators are used in many places. This includes vehicle service stations and industrial sites with oily wastewater. They help keep these places in line with environmental rules.

It’s important for these systems to handle flow rates well. This prevents them from getting too full and not working right.

Common Types

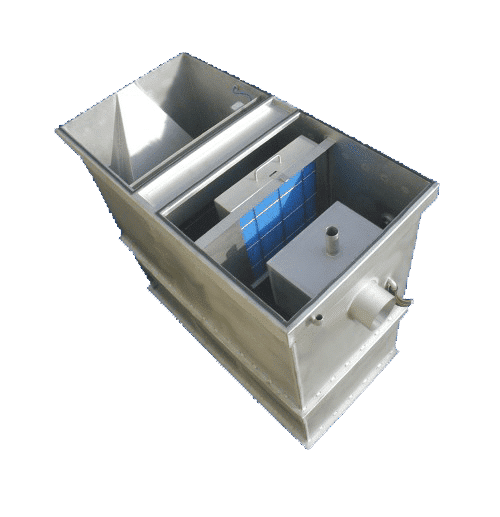

There are different types of oil water separators. These include gravity, enhanced coalescing, and centrifugal models. Each one is good for different needs.

Gravity separators use gravity to separate oil and water. Enhanced coalescing separators can remove more contaminants. You can learn more about these at this resource.

The Role of Separation Efficiency

Separation efficiency is key for oil water separators. It helps industries manage wastewater well. High efficiency means harmful oils and contaminants are removed, lowering environmental risks.

Understanding its importance helps industries follow rules and save money.

Importance in Industry

The role of separation efficiency is huge in industry. Oil water separators can remove 90% to 95% of oil droplets over 100 microns. In places like refineries, API separators can take out up to 85% of oil in wastewater.

This is critical for keeping operations safe and protecting the environment.

Environmental Compliance

Using high-efficiency separation tech is key for following environmental rules. Good oil separation cuts down on oily discharges’ harm. This meets EPA standards.

Getting wastewater oil levels below 15 mg/L helps avoid fines and penalties.

Economic Benefits

Oil water separators bring big economic wins for industries. They cut down on fines and let companies reuse oil, making money. Plus, they save on costs by handling wastewater efficiently.

North American Hydrocarbon Discharge Limits

In North America, rules for hydrocarbon discharges into water are strict. These rules help keep water quality good and control how vessels and industries work. It’s key for businesses to follow these rules.

Standards and Regulations

The U.S. Environmental Protection Agency (EPA) sets rules for oil discharge limits. These rules cover about 85,000 vessels under the Vessel Incidental Discharge Act (VIDA). Companies must follow the 2013 National Pollutant Discharge Elimination System (NPDES) Vessel General Permit (VGP) rules.

This includes ships, passenger vessels, and bulk carriers. They must keep oil discharges under 10 PPM to meet standards.

The 10 PPM Benchmark

The 10 PPM benchmark is a key goal for many companies. Meeting this standard helps protect the environment and follow local laws. Industries like petrochemicals and autos are affected by this goal.

Using better oil water separators can help meet this goal. This makes it easier for companies to follow the rules.

Consequences of Non-Compliance

Not meeting oil discharge limits can cause big problems. Companies might face legal issues, fines, and damage to their reputation. These costs can be more than the benefits of not following the rules.

So, investing in better separation technologies is important. It helps companies stay efficient and protect the environment.

Freytech Inc. and Separation Technology

Freytech Inc. leads in oil water separation, providing top-notch solutions that meet strict standards. They focus on both environmental care and making operations more efficient. This makes Freytech a key player in the industry.

Introduction to Freytech Inc.

Freytech Inc. is a leader in oil water separator technology. Their systems can separate oil as low as 5 PPM. They even handle trace amounts of emulsified oil at 0.1 PPM. This high precision makes Freytech a top choice for those who value environmental standards and sustainability.

Enhanced Coalescing Technology

Freytech uses advanced coalescing technology for better oil separation. This method ensures the separated oil is 99.7% pure. The technology works well with various wastewater types, including industrial ones.

Comparison with Standard Separators

Comparing Freytech’s separators to standard ones shows a big difference. Standard separators usually get around 10 PPM. Freytech’s systems, on the other hand, offer better separation and use reusable media. This not only boosts efficiency but also cuts down on costs. Freytech is a key partner for industries looking to reduce their environmental impact.

Achieving 5 PPM Separation Efficiency

To reach a 5 PPM efficiency, advanced separation methods are key. Freytech’s separators use top-notch coalescing media and designs. These improve the separation process, making it possible to meet strict discharge standards.

Advanced Techniques

Advanced methods in Freytech’s systems are critical for low oil levels. Coalescing plate separators boost efficiency with their special design. Keeping the right temperature also helps by making oil less viscous and more dense.

Maintenance Considerations

Keeping oil water separators in top shape is vital. Regular checks and upkeep of coalescing media are necessary. Freytech’s design makes maintenance easy, ensuring effective separation and meeting regulations.

Performance Demonstrations

Performance tests show how well these separators work. They can remove oil from water to 5 PPM or less. These tests prove Freytech’s systems can handle different conditions, making them reliable for real-world use.

Separating Emulsified Oil

Emulsified oil is hard to separate from water because it mixes well with it. Old methods don’t work well, leading to poor results. This is a big problem in places where following rules is very important.

Challenges with Emulsified Oil

Getting rid of emulsified oils is tough because the tiny droplets are hard to separate. Regular oil-water separators can only get 30% to 50% of the oil out. To meet stricter rules, new and better ways to separate oil from water are needed.

How Freytech Achieves 0.1 PPM

Freytech uses advanced technology to deal with emulsified oils. They can separate oil down to 0.1 PPM. Their special separators make the process much better, getting over 99% of free-phase oils out.

Examples of Separators in Action

Real-world examples show how well Freytech’s technology works. Many industries have used Freytech’s separators and seen great results. These stories show how new technology is making a big difference in how we handle oil and water.

Types of Hydrocarbons Handled

Knowing what hydrocarbons oil water separators handle is key for keeping our environment clean. Freytech’s tech tackles the different kinds of hydrocarbons. Here are the main types these separators manage well.

Motor Oil and Diesel

Freytech’s oil water separators are great at separating motor oil and diesel fuel. These are common in places like car shops and car washes. They make sure these oils don’t mix with water, keeping our environment safe.

Gasoline and Jet Fuel

They also handle gasoline and jet fuels well. These need special care because of their unique makeup. By treating them right, we avoid harming our environment and follow the rules.

Refined Hydrocarbon Variants

Freytech’s systems can handle many types of refined hydrocarbons. They show how well these separators work on different oils. Thanks to advanced tech, they meet the needs of many industries.

Reusability of Coalescing Media

Using reusable coalescing media in oil water separators is changing how we treat wastewater. This new method makes processes more sustainable and saves money.

Benefits of Reusability

One big plus is less waste and lower costs for replacements. Freytech’s reusable media lasts longer, cutting down on downtime and upkeep. It boosts efficiency and meets environmental rules.

Maintenance Practices

Keeping reusable media in top shape is key. Cleaning them every few months keeps them working well. Regular checks help spot problems early, keeping the system running smoothly.

Longevity and Cost Efficiency

Reusable media’s long life adds to the cost savings of oil water separators. Businesses save money over time with this durable tech. Choosing Freytech’s separators is a wise move for dependable wastewater treatment.

If you want to improve your wastewater treatment, contact Freytech. They offer solutions to meet industry standards. Reach out to Freytech Inc. at +1 (305) 372-1104 for personalized advice.

Utilizing the Patented Oil Skimmer

The patented oil skimmer by Freytech makes oil recovery better when used with oil water separators. This new tech is made for quick and effective oil removal from wastewater.

Operation of the Oil Skimmer

The oil skimmer works with advanced tech to get more oil. It has a continuous flow to remove oil from water. It uses special media to catch over 99.9% of oil droplets 20 microns or bigger.

This means even tiny oil particles are caught. This is key for getting oil that’s very clean.

Drainage Process and Efficiency

The drainage process of this oil skimmer is fast. Oil is quickly moved to a separate container. This keeps the process running smoothly without long stops.

The design of the oil skimmer helps remove oil constantly. This keeps facilities running well and boosts efficiency in oil recovery.

Purity of Separated Oil

The oil skimmer by Freytech makes oil very clean. It can be up to 99.7% pure. This shows how well Freytech’s tech works.

It makes it possible to reuse the oil. This helps industries be more sustainable.

Recycling Efficiently Skimmed Used Oil

Recycling used oil is key for both the economy and the environment. By skimming treated oil, businesses can turn waste into a valuable product. This process supports a circular economy, encouraging companies to be sustainable and profitable.

Economic Value of Skimmed Oil

The value of recycled oil is big. Companies that manage their oil waste well save money and can sell the recycled oil. This makes it worth investing in better oil/water separators.

Recycling Process Overview

The recycling of skimmed oil uses advanced methods to clean and refine it. This process changes the game for businesses in oil separation. It ensures the oil is of high quality, ready for the market or other uses.

Environmental Impact

Recycling used oil is good for the planet. It stops oil from ending up in landfills and keeps water sources clean. This follows environmental rules and builds trust with the public.

For more on oil separation and recycling, check out this link. It has info on the latest technologies and methods.

Case Studies and Success Stories

Freytech keeps finding new ways to help different industries. Their oil water separators have shown great results in many case studies. These stories show how Freytech improves wastewater treatment and meets regulations.

Industries Benefiting from Freytech

Many sectors, like automotive and petrochemical, have seen big changes in their wastewater management. Thanks to Freytech, they can now handle wastewater better. This shows how Freytech’s solutions lead to cleaner processes and less environmental harm.

Real-World Implementations

Places around the world have started using Freytech’s oil separation systems. They follow the rules better and save money. These examples prove Freytech’s success and its strong reputation in the industry.

Testimonials and Results

Customers always talk about how well Freytech’s oil water separators work. They share numbers that show big improvements in how well they separate oil and meet rules. This proves that investing in Freytech’s tech is a smart choice for keeping water clean.

Conclusion

Oil water separators play a key role in industrial settings. They help meet environmental rules and save money. Technologies like coalescing separators and hydrocyclones can remove oil levels below 10 ppm. This boosts efficiency.

In conclusion, advanced separation tech is essential for modern wastewater management. It shows how important these systems are.

Future Developments in Oil Water Separation

The future of oil water separation looks bright. New technologies aim to improve efficiency and reduce harm to the environment. We can expect better filtration and automated upkeep.

This focus on eco-friendly solutions is vital. It shows the need to keep up with these advancements.

Contact Freytech Inc. for More Information

If you want to improve your wastewater treatment, contact Freytech. They offer solutions to meet industry standards. Reach out to Freytech Inc. at +1 (305) 372-1104 for personalized advice.