Ever thought What are Above Ground Oil Water Separators Used For? or about how industries keep their wastewater clean of harmful oil and grease? Not doing so can lead to fines over $100,000. Above ground oil water separators are key in this effort, making sure contaminants are removed before water is released. These systems are vital for sectors like automotive, mining, and construction, where water often gets contaminated with hydrocarbons.

Learning how these systems work shows their importance in protecting the environment. It also helps businesses avoid big economic penalties.

Key Takeaways

- Above ground oil water separators are vital for industries confronting oil and grease contamination in wastewater.

- Effective separation helps avoid costly legal penalties associated with environmental regulations.

- Various types of oil water separators cater to specific industry needs.

- Regular maintenance and inspections are key to keeping oil water separators efficient.

- Using these systems can save a lot of money in water disposal costs.

Introduction to Above Ground Oil Water Separators

An oil water separator is a key device for removing oil, grease, and solids from industrial wastewater. It is designed to meet strict environmental rules and support sustainability. These separators work well in many settings, making them vital for managing wastewater.

Definition of Oil Water Separators

The main job of an oil water separator tank is to separate oil from water. It uses buoyancy to help oil globules float to the top for easy removal. A good separator ensures water meets discharge limits set by laws, which is 10 ppm for oily waste.

Operators must make sure their systems can handle different types of oil and emulsions.

Importance of Separation Efficiency

How well a separator works is key to reducing environmental harm and following discharge rules. The better the separator, the more harmful hydrocarbons it can remove from wastewater. Companies like Freytech Inc. have made systems that can get as low as 0.1 ppm, a high standard.

Dealing with tough wastewater, like high-viscosity oils, requires advanced designs for best results. Regular checks with an Oil Content Monitor (OCM) are needed to keep standards up and alert alarms if oil levels get too high.

Applications of Oil Water Separators

Oil water separators are key in many industries that deal with wastewater. They help keep the environment clean and make operations more efficient.

Industrial and Commercial Uses

Many sectors use oil water separators to handle wastewater. Places like steel factories, mines, and food processing plants need them. They also help with washing tanks and heavy equipment.

These systems separate oil from water, making treatment better. Coalescer separators make oil droplets merge, helping to remove them faster.

Environmental Protection

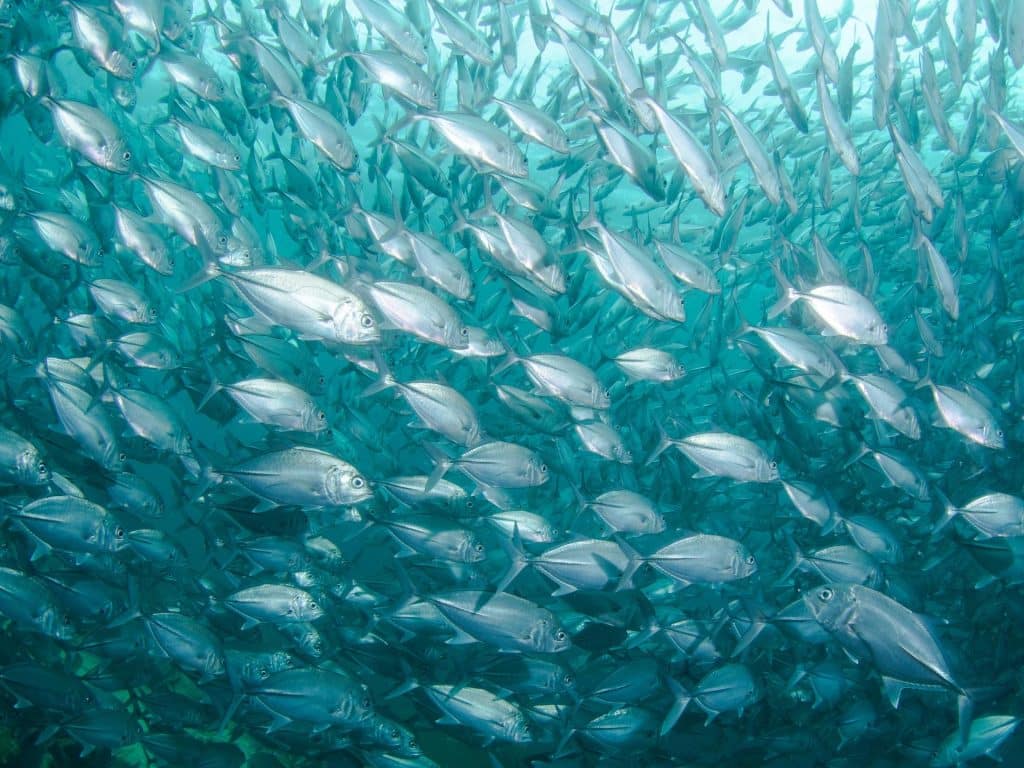

Oil water separators protect the environment by reducing pollutants in water. They manage stormwater runoff and lower hydrocarbon levels. This is good for aquatic life.

Following rules on hydrocarbon discharge means cleaner water is released. Keeping these systems in good shape also saves money and helps the environment.

Understanding Hydrocarbon Discharge Limits

In North America, the rules for wastewater are strict. They set a limit of 10 Parts Per Million (PPM) for hydrocarbons. Companies must follow these rules to avoid big fines and legal troubles. They need systems that can separate hydrocarbons from water very well.

North American Standards

The rules for hydrocarbon discharge are key for the environment and safety. The 10 PPM limit helps keep water clean and safe for people. Companies like Freytech use advanced tech to meet these standards, even going beyond them.

Importance of Compliance

Following the rules for hydrocarbon discharge is very important for businesses today. Not following them can cause big problems, like fines and damage to reputation. Using top-notch oil water separation tech is a must. It helps meet standards and makes operations more sustainable, helping the environment.

Freytech Inc. Solutions for Oil Water Separation

Freytech Inc. is a leader in oil water separator solutions for industries. Their systems use advanced technology to improve separation efficiency. This is important for places with strict environmental rules.

Overview of Freytech’s Technology

The Freytech Inc. oil water separator is built with the latest engineering. It works well in mining, steel, and food processing. Their technology cuts oil levels in water, meeting strict North American standards.

It can lower oil levels to under 5 PPM. Even when water starts with 2000 PPM oil, it works.

Enhanced Coalescing Technology Explained

At the core of Freytech’s technology is enhanced coalescing. It uses special media to gather oil droplets. This makes them heavier and easier to skim off.

This technology helps meet and often beat environmental standards. It’s key for managing wastewater in many industries.

Efficiency Ratings of Freytech Separators

Freytech separators focus on high oil water separator efficiency. They help industries meet strict standards. These solutions can remove hydrocarbons to levels far below what’s needed.

This means industries can handle wastewater responsibly. They can be sure they’re following the rules.

Achieving 5 PPM Separation Efficiency

Freytech’s separators work well with flow rates from 1 to 100 gallons per minute. This makes them flexible for different needs.

It ensures consistent 5 PPM separation efficiency. This is great for both commercial and industrial settings.

Trace Amounts Handling with 0.1 PPM

Freytech systems also handle trace amounts well, reaching 0.1 PPM separation efficiency. They use coalescing media with lots of surface area. This helps remove even tiny amounts of oil from water.

This shows how important advanced technology is. It helps keep our environment safe.

Types of Hydrocarbons Removed

Oil water separators are key in managing hydrocarbons in wastewater. They handle different oil types that can pollute water systems. Their design makes sure they can efficiently treat various hydrocarbon substances.

Common Hydrocarbons in Wastewater

Many industries face various hydrocarbons in their wastewater, like motor oil, diesel, gasoline, and jet fuel. Each oil type has its own challenges for separation. The lightness of these hydrocarbons affects how well oil water separators work.

Knowing what hydrocarbons are present helps plan maintenance and operations. This ensures the separators work at their best.

Specifics on Oil Types

The success of oil water separators depends a lot on the oil types they treat. Lighter oils are easier to separate because they float up quickly. But heavy oils need special designs to separate properly.

Regular checks and upkeep are vital for these separators to meet environmental standards. Keeping maintenance records helps follow rules and protect the environment.

Reusable Coalescing Media Technology

Reusable coalescing media technology is a big step forward in oil water separator systems. It cuts down on waste and boosts sustainability. This makes it a top pick for keeping oil water separators in good shape.

By using coalescing media that lasts a long time, places can save a lot of money. They can also keep their systems running smoothly.

Advantages of Reusable Media

Reusable coalescing media has many benefits. It can be used over and over again without needing to be replaced often. This technology helps remove oils very well, leaving water almost oil-free.

It’s easy to clean, which makes it last longer. This ensures it works well all the time. It’s a big help in keeping oil water separators in top shape.

Maintenance and Longevity

Keeping oil water separators in good working order is key. Regular cleaning is important to keep the media working well. It also makes the media last longer.

By doing this, places can save money and help the environment. Taking good care of the media shows a commitment to keeping things running smoothly and efficiently.

The Role of Oil Skimmers

Oil skimmers are key in separating oil from water. They use special technology to pull out oil, grease, and other pollutants from wastewater. This makes the water cleaner and safer.

Functionality of Patented Oil Skimmer

The special oil skimmer technology works in different ways for different needs. Belt oil skimmers are great at getting oil out of water. Tube oil skimmers work best when there’s a lot of oil.

These devices help keep industrial water clean. They stop oil from clogging pipes and filters. This makes the water treatment system work better.

Oil skimmers run all the time, unlike absorbents that need to be replaced. This makes them a reliable choice for keeping water clean.

Benefits of High Purity Oil Recovery

Oil skimmers can make water almost completely clean, up to 99.7%. They turn waste into something useful. This helps the environment and saves money on waste disposal.

Places like CNC machining and food processing need oil-free coolants. Oil skimmers help keep these coolants clean. This keeps operations running smoothly and avoids fines.

Recycling and Economic Benefits

Using oil water separators in industries brings big advantages. They help recycle oil from operations. This recycled oil is not only good for the planet but also brings in money.

Valuing Skimmed Oil

Skimmed oil is very valuable. It helps cut down on hazardous waste, saving companies money. Treating oil and water separately is cheaper than mixing them.

Companies can make more money by selling the recycled oil. This shows how oil water separators can be good for business.

Cost-Effective Recycling Solutions

Oil-water separation technology is good for the environment and saves money. It makes equipment last longer, saving on repairs. Closed-loop systems can recycle up to 95% of wastewater.

Following EPA rules also saves money by avoiding fines. Companies can see a 150% return on investment in just three years. This proves oil water separators are a smart long-term choice.

Conclusion

Above ground oil water separators are key in many industries. They help follow environmental rules and make operations better. These separators can remove up to 99% of oil and solids from water. This greatly lowers pollution risks and helps meet industry standards.

Summary of Benefits

Freytech Inc. provides top-notch oil water separation technology. It works well with different types of fluids. Their three-stage separator boosts efficiency and cuts down on harmful emissions.

This is great for industries like petrochemicals and maritime. They often have to follow strict rules. Freytech also lets businesses tailor separators to fit their needs. This can help save resources and boost profits.

Contact Information for Further Inquiry

If you want to learn more about Freytech’s solutions, call them at +1 (305) 372-1104. Talking to Freytech helps businesses make smart choices. They focus on following rules and being sustainable.