Have you ever thought Can Oil Skimmers Remove All Types of Oil? or about if a simple skimmer can handle all kinds of oils in our waters? The topic of oil skimmers’ effectiveness has gained a lot of attention, thanks to big environmental disasters like the Exxon Valdez oil spill in 1989. These tools are made to pull oil out of water, but how well they do it depends on the oil type and the water conditions. We’ll look into if oil skimmers can get rid of all types of oil, how different they are, and the various equipment used for oil removal today.

Key Takeaways

- Oil skimmers played a key role during the Exxon Valdez oil spill.

- Weir type skimmers can remove oil at rates over 25 cubic meters per hour.

- Oleophilic skimmers can take out many oils with a specific gravity less than water.

- How well they work depends on the water and the oil type.

- Different skimmer designs affect their use and efficiency.

- The marine industry produces a lot of waste oil that needs to be removed efficiently.

Understanding Oil Skimmers and Their Functionality

Oil skimmers are key in many industries for removing oil from water. They work by using special designs and principles. This helps keep our environment clean and makes equipment work better.

What Are Oil Skimmers?

Oil skimmers are made to take oil off water surfaces. They are used in places like factories, oil fields, and when cleaning up spills. These tools pick up oil that floats on the surface, not treating all the water.

They help stop oil from getting into coolants, which is bad for machines. This can cause problems like needing to replace coolants more often and wearing out tools. So, having good oil skimmers is very important.

How Do Oil Skimmers Work?

Oil skimmers work because oil is lighter than water and floats. They use different systems like belts, discs, and tubes to catch oil. The oil sticks to these surfaces and is then collected in tanks.

Putting oil skimmers near where oil comes from makes them work better. This cuts down on upkeep, saves time, and saves money. There are many types of oil skimmers, so picking the right one can make things run smoother.

Types of Oil Skimmers Available

Oil skimmers are key tools for removing oil from water and other fluids. They use different technologies to do this. Knowing the types of oil skimmers helps facilities pick the right one for their needs. Here are four main types of oil skimmers on the market.

Vortex Oil Skimmers

Vortex oil skimmers use swirling water to separate oil from water. They work well in areas with changing water levels. These devices keep performing well, even in tough conditions.

Disk Oil Skimmers

Disk oil skimmers have rotating discs that grab oil with little water. They need to be fully in the water to work best. These skimmers are great for places where oil mixes with water.

Belt Oil Skimmers

Belt oil skimmers have a belt that moves through the oil-water mix. Oil sticks to the belt and is then collected. These skimmers can be made in different lengths for bigger tanks.

Freytech’s Enhanced Coalescing Technology

Freytech’s technology is a big step forward in oil skimming. It uses special media to separate oil very efficiently. This technology works well with many types of oil, making oil skimming more effective. For more on the best oil skimmers, check out Freytech’s oil extraction solutions.

Industry Regulations and Standards

Companies in oil production must follow strict rules to protect the environment. These rules set limits on how much oil can be released into water. In North America, the limit is 10 PPM, which helps keep the environment safe.

North American Hydrocarbon Discharge Limits

Keeping pollution levels low is key in North America. Rules say that water released must not have too much oil in it. Agencies watch over this to make sure companies follow these rules.

Using good oil skimmers helps meet these standards. This is important for keeping our water clean.

Importance of Maintaining Compliance

Following environmental rules saves money and improves a company’s image. Companies that care about the environment attract more customers. They also work better and avoid oil spills.

Investing in oil skimmers helps meet these standards. It also protects our natural resources. For more info, visit Freytech’s website.

Efficiency of Oil Separators

It’s important to know how well oil separators work. They help keep oil out of water, which is key for following environmental rules. Choosing the right technology is critical for many uses.

What is Separation Efficiency?

Separation efficiency shows how well an oil separator works. It’s key for industries that must keep their water clean. Using top-notch technologies helps companies follow rules better and work more efficiently.

Freytech’s 5 PPM Separation Efficiency

Freytech oil skimmers are known for their high efficiency of 5 PPM. This means they can make water much cleaner. It helps companies meet environmental standards better.

These technologies break down oil well. This leads to less need for fluid changes and less waste.

Trace Hydrocarbon Removal: 0.1 PPM

Freytech oil skimmers can remove tiny amounts of hydrocarbons, down to 0.1 PPM. This is great for industries looking to improve their environmental impact. They keep water clean and protect ecosystems, even in polluted areas or during spills.

Common Oil Types That Can Be Skimmed

Identifying common oil types for skimming is key to effective oil recovery. The right oil skimming technology is vital for keeping operations running smoothly. This is true, mainly in industrial settings where oil spills are common.

Motor Oil

Motor oil often needs to be removed from coolant systems to avoid environmental harm. It can cause bacterial growth, bad smells, and shorten coolant life. Using good oil skimming tech helps remove motor oil quickly. This keeps coolant systems working longer and cuts down on maintenance costs.

Diesel and Gasoline

Diesel and gasoline are often found in industrial settings and need to be removed. They can cause big problems if not handled right. Skimming technology that targets these fuels helps keep operations running smoothly and meets environmental rules.

Jet Fuel and Refined Hydrocarbons

Jet fuel and refined hydrocarbons are tough to handle during recovery. Advanced skimmers, like those from Freytech, are up to the task. They ensure these materials are handled properly, keeping operations in line with rules and protecting the environment.

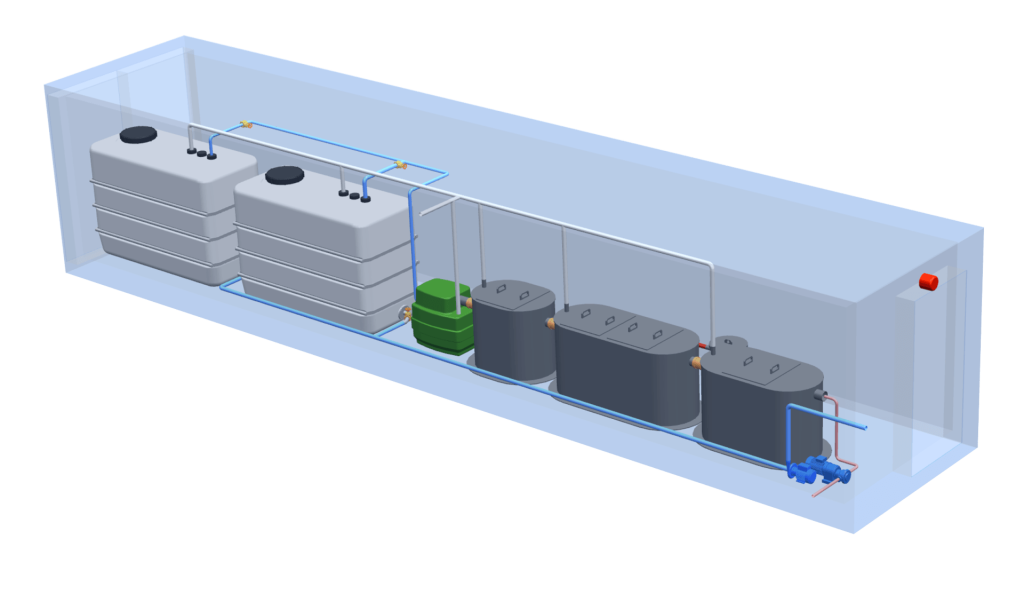

Advantages of Using Enhanced Coalescing OWS

Enhanced oil-water separators (OWS) bring many benefits. They improve oil recovery and make operations more efficient. A key feature is their reusable coalescing media. This lets Freytech’s media be cleaned and reused, saving resources and reducing waste.

Reusable Coalescing Media

The reusable media cuts down on costs and supports green practices. It helps companies reduce waste and show they care about the environment. Using these systems can make managing wastewater more efficient and compliant.

Easy Maintenance and Longevity

Maintenance for Freytech’s systems is simple, making them even more appealing. Regular checks on oil levels and parts help them last longer. Servicing every 3-6 months keeps operations running smoothly and meets local rules.

Compliant systems also prevent expensive fines. These fines can reach up to $100,000 for not following rules.

Patented Oil Skimmer Technology

The patented oil skimmer technology is key to separating oil from water well. It makes the final product better, allowing for recycling and saving on disposal costs. This technology is vital for industries that need efficient oil recovery, reducing environmental harm and improving resource use.

Environmental Impact and Recycling

In industrial settings, cutting down on oil discharge is key. Oil pollution harms aquatic ecosystems, causing big environmental problems. Keeping water clean is vital for wildlife and human health, showing the need for good oil management.

The Importance of Reducing Oil Discharge

Less oil in waterways helps protect the environment. Oil skimmers have changed how businesses handle pollution, helping them follow rules and lessen harm to ecosystems. By removing oil from coolant systems, companies avoid equipment failures and save on repairs.

This approach protects machines and nature.

How Efficiently Skimmed Oil Is Recycled

Skimmed oil is a valuable resource that can be recycled. This not only helps the environment but also makes economic sense. Companies using sustainable oil skimmers follow green practices and save money by recycling oil into new products.

This shows how protecting the environment and improving operations go hand in hand, even in industries like CNC machining.

Choosing the Right Oil Skimmer for Your Needs

Choosing the right oil skimmers is key to effective oil recovery. It’s important to know how much and what type of oil your processes produce. This helps match the equipment to your needs.

Deciding if you face large amounts of oil or less frequent contamination is vital. It affects what oil recovery equipment you should choose.

Assessing Your Oil Recovery Requirements

Understanding your oil recovery needs is the first step. For example, facilities with lots of contaminated coolant need constant oil removal. This improves coolant efficiency and cuts down on harmful emissions.

Using specialized devices like Freytech´s oil skimmer can also help. It keeps machine tools running longer by solving overflow problems. Knowing if you have shallow sumps or larger tanks helps choose the right skimmer.

Factors to Consider When Selecting Equipment

Several factors are important when picking oil recovery equipment. These include the type of oil, how fast you need to remove it, tank size, and your budget. For instance, disk skimmers work well for steady fluid levels.

Custom-built long reach belt skimmers are great for bigger and more variable tank sizes. Also, picking a skimmer that automates coolant delivery can cut downtime and boost productivity. The Sidewinder skimmer is a good choice for tight spaces, ensuring better oil removal and a cleaner work area.

Conclusion: Maximizing Oil Separation Efficiency

To get the best results in oil management, using advanced tech is key. Working with leaders like Freytech Inc. gives businesses top-notch solutions. These solutions boost efficiency and meet tough environmental rules. Freytech’s oil skimmers meet different needs and types of oil, helping companies improve oil separation.

The Benefits of Partnering with Freytech Inc.

Using Freytech’s advanced oil skimming tech helps avoid costly fines and cuts wastewater treatment costs. Studies show it can make industrial processes 30% more efficient. This boosts equipment performance. Freytech’s benefits also include safer workplaces, reducing the risk of injuries from oily surfaces.

Contact Information and Next Steps

If you’re looking for effective oil management solutions, Freytech Inc. is ready to help. Call +1 (305) 372-1104 for expert advice and tailored suggestions. Taking the next steps is important for keeping your facility safe and efficient.