In today’s world, protecting our environment is key. A big question is: Are Above Ground OWS Systems Effective? or Do above ground OWS systems really help keep our water safe? As companies work to follow strict rules, it’s important to know if OWS technology works well. These systems are made to clean wastewater by removing harmful substances, helping companies follow the law and protect the environment.

This article explores how these systems work. It looks closely at the advanced tech behind them, like what Freytech Inc. offers.

Key Takeaways

- Above ground OWS systems provide critical oil-water separation necessary for industrial compliance.

- Freytech’s systems demonstrate advanced coalescing media technology with significant surface area for higher efficiency.

- Clean water discharge is essential to meet environmental regulations and minimize pollution.

- These systems offer a compact design while handling varying flow rates from 1 to 100 GPM.

- With effective oil separation, they ensure that treated water meets stringent contamination standards.

- Regular maintenance and automation features enhance operational efficiency and reliability.

Understanding Oil Water Separator (OWS) Technology

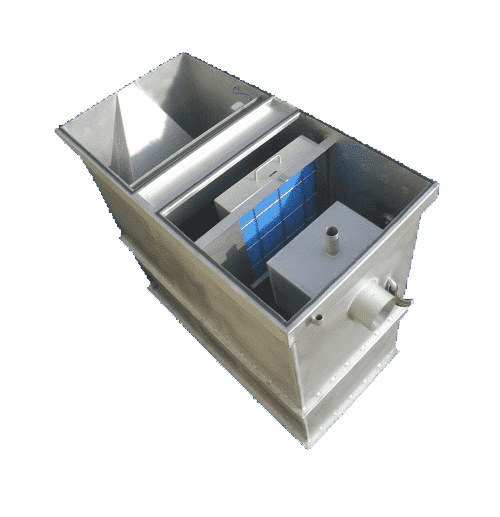

The above ground oil water separator is key in reducing oily wastewater’s harm to the environment. It separates oil, grease, and hydrocarbons from water, helping meet strict environmental rules. These systems are vital in many industries, showing their role in green practices.

What is an Oil Water Separator?

An oil water separator uses different methods to clean contaminated water. It’s a must-have in fields like oil and gas, manufacturing, and cars. The top systems use gravity, coalescing plates, or centrifuges, with gravity being the most common because it’s affordable and reliable.

How OWS Systems Function

Wastewater flows into the OWS, where a baffle guides it. This reduces turbulence and lets solids settle. Oil droplets, being less dense, float up and separate from the water.

This separation boosts the treatment process and helps follow rules like North American hydrocarbon limits of 10 PPM. For even better results, advanced coalescing tech can reach 5 PPM or 0.1 PPM with systems like Freytech’s. To discover more, check out oil water separators technology online.

Importance of Clean Water Discharge

Keeping water clean is key for our environment and following the law. In the U.S., strict rules control how industrial waste is treated. This includes removing harmful substances like oil and grease. Oil water separators (OWS) are essential in this effort, making sure water is clean before it’s released.

Environmental Regulations in the U.S.

In the U.S., laws set limits on what can be in water. For example, oil levels in water can’t exceed 10 Parts per Million (PPM). States like North Carolina stick to these rules closely. Companies must use the right technology, like advanced oil water separators, to follow these laws and avoid fines.

This careful management of wastewater helps protect our waterways and supports a green future.

North American Hydrocarbon Discharge Limits

In North America, following oil discharge limits is very important. Technologies like those from Freytech Inc. can remove oil to levels as low as 0.1 PPM. These systems can handle different flow rates and come in various sizes, fitting many industrial needs.

Places like factories and car washes can use these systems to improve their water treatment. This helps them meet both local and national environmental laws in the U.S.

Freytech Inc.’s Commitment to Efficiency

Freytech Inc. is all about providing affordable above ground OWS solutions. They aim to meet and go beyond what the industry expects. Their systems can separate oil from water down to 5 PPM, which is what the law requires.

Their advanced technology makes these systems work better and harm the environment less. This shows their dedication to being efficient.

Achieving 5 PPM Separation Efficiency

Freytech’s systems can separate oil from water as well as 5 PPM. This is a big win for industries that deal with oily wastewater. It helps them avoid fines for not following the law.

These systems work well even when handling small amounts of water. They are perfect for places like construction and trucking sites.

Enhanced Coalescing Technology Explained

Freytech’s secret to success is their advanced coalescing technology. It makes sure oil droplets and water get in close contact. This leads to a 99% removal rate for oil droplets over 20 microns.

They use top-notch materials and smart design to avoid clogs. This means their systems can last over 20 years with little upkeep. It makes Freytech’s solutions a smart choice for saving money.

Benefits of Freytech Separator Packages

Freytech separator packages bring many benefits, mainly in wastewater treatment. They are great at separating different types of hydrocarbons like motor oil and gasoline. These systems are among the best above ground OWS systems, helping companies meet environmental rules.

Separation of Various Hydrocarbons

Freytech separators use advanced tech to work well. They keep hydrocarbon levels very low, even when they start high. These systems handle different types of hydrocarbons, meeting many industrial needs.

They help follow strict wastewater rules. They cut oil levels in water to under 15 PPM. Some models even get levels as low as 0.1 PPM.

Reusable Coalescing Media Advantages

The coalescing media in these separators is special. It’s reusable and easy to keep up. Regular cleaning keeps it working well for a long time.

This makes the system efficient and green. It saves money and helps the environment. This makes it a wise choice for many industries.

Advanced Oil Separation Capabilities

Freytech’s oil water separator (OWS) systems lead the industry with their advanced oil separation. They can separate oils as low as 0.1 PPM. This is key, as it’s hard to separate emulsified oils from water.

Achieving 0.1 PPM Separation Efficiency

Freytech’s design uses coalescing media and flow dynamics to remove small oil remnants. This meets strict environmental rules and ensures water quality.

Handling Emulsified Oils Effectively

Freytech’s systems excel in separating emulsified oils. Their design boosts performance and reliability. This helps facilities meet U.S. EPA standards, protecting water resources.

Using above ground OWS maintenance tips can also improve system longevity. This allows for sustainable operations over time.

The Role of Patented Oil Skimmers

Patented oil skimmers are key to making Freytech’s oil-water separator systems better. They help drain the separated oil automatically or mechanically into special containers. This way, the system can make sure the oil is 99.7% pure. This purity is vital for getting the most value from the recovered oil.

Having such pure oil means less cost for extra processing or extraction. This is a big win for businesses.

Automatic and Mechanical Draining

The skimmers make draining oil fast and easy. This quick transfer keeps the oil clean and pure. It also cuts down on the time the oil spends in the system.

As the system works, the skimmers remove impurities well. This keeps the system running smoothly and efficiently.

Purity Levels of Skimmed Oil

Keeping the skimmed oil very pure is important for efficiency. Freytech’s systems meet high standards by removing over 99.9% of big droplets. The special coalescing media helps reach the needed purity for recycling or selling.

This not only helps meet environmental rules but also brings economic benefits. Businesses can make money from clean oil.

Eco-Friendly Recycling of Used Oils

Efficiently skimmed oil is a valuable resource for eco-friendly recycling. Freytech’s above ground oil water separator (OWS) systems make recycling easier. This helps industries be more sustainable and saves money on waste disposal.

Value of Efficiently Skimmed Oil

The oil skimmed efficiently can be up to 99.9% pure. This makes it perfect for recycling. Companies can use this oil again, which saves money and is good for the planet.

Using Freytech’s OWS technologies helps separate oil well. This keeps operations running smoothly and supports sustainable practices.

Recycling Processes at No Cost

Freytech’s solutions make recycling easy and often free. Their multi-stage closed loop treatment systems recover oil constantly. This means no extra costs for disposal.

The OWS systems also use less water and don’t need expensive chemicals. This approach boosts resource use and shows a commitment to the environment.

Applications of Above Ground OWS Systems

Above ground OWS systems are used in many industries. They help meet environmental rules and make operations better. They also lower the risk of oil spills.

Industries That Benefit from OWS

The automotive, marine, petrochemical, and municipal sectors use OWS systems a lot. These sectors need good oil-water separation to follow strict environmental rules. For example, the marine industry uses special systems for oil spills. The petrochemical industry focuses on reliable wastewater management.

Case Studies of Successful Implementation

Places using above ground OWS systems have seen big improvements in treating wastewater. For example, using high-end stainless steel CPIs makes the systems last longer and resist corrosion. These systems can handle different oil levels and follow the Clean Water Act. This shows the need for effective oil-water separator solutions in industries.

Comparing Above Ground vs. Below Ground OWS Systems

Businesses have to choose between above ground and below ground oil-water separator (OWS) systems. Each has its own benefits, making it key to know the differences. This helps find the right system for your needs.

Advantages of Above Ground Systems

Above ground OWS systems have clear advantages. They can be set up quickly, cutting down installation time by 40-60%. This means maintenance can be done 25% faster, boosting efficiency.

These systems last longer, from 15 to 20 years, compared to 10 to 15 for below ground ones. They meet environmental rules up to 90% of the time, lowering risk. Plus, they cost 15% less to run each year because maintenance is easier.

Potential Limitations of Below Ground Systems

Below ground OWS systems have their own set of challenges. They cost 20-30% more to install, which can be a budget hit. Maintenance is harder, leading to more operational issues and costs.

There’s also a higher risk of groundwater pollution, which is a big concern in areas with high water tables. Their environmental compliance rates are about 75%. These factors can affect how well they manage wastewater.

Maintenance and Operation of OWS Systems

Keeping OWS systems in top shape is key. Following some simple maintenance tips can make a big difference. Regular checks for wear and damage are a must.

Cleaning the coalescing media is also important. It helps the system work better. Watching for any signs of trouble keeps the system running smoothly.

Best Practices for Long-Term Use

Using OWS systems right can really boost their performance. Regular maintenance is a must. This includes checking and calibrating parts to avoid problems.

It’s also good to keep an eye on alarms and sensors. Keeping records of maintenance is important. This ensures the system meets standards, like keeping oil content under 15 ppm.

Troubleshooting Common Issues

Fixing common problems in OWS systems is essential. Issues like blockages or oil content above 15 ppm need quick action. Cleaning or replacing filters might be needed.

Checking the system’s panels and gauges regularly helps spot problems early. These steps help keep OWS systems running well.

Cost-Effectiveness of Freytech OWS Solutions

Freytech’s above ground oil water separator (OWS) solutions are made to save money. They help businesses follow environmental rules and cut down on costs. This is because they manage wastewater well.

Analysis of Operational Costs

Understanding the cost savings of Freytech’s OWS is key. These systems cut down on the need for expensive suction truck services. This is a big deal for industries like mining or power generation.

The reusable coalescing media in Freytech systems lasts for years with little upkeep. This adds to the long-term savings.

Return on Investment Considerations

Businesses should think about the money saved from avoiding fines for not following environmental rules. Freytech’s systems are very good at keeping oil levels low. This means less chance of getting fined.

These systems can handle different flow rates, from 25 to over 640 gallons per minute. This makes them flexible for various needs. Investing in Freytech’s solutions is good for the environment and the wallet.

Contact Freytech Inc. for More Information

If your business wants to improve its wastewater treatment, reach out to Freytech Inc. They are experts in oil water separator (OWS) technology. This helps companies meet strict environmental rules. Start by calling them for a phone consultation to find the right solution for your needs.

Phone Consultation: +1 (305) 372-1104

Call Freytech at +1 (305) 372-1104 for a phone consultation. This is a great first step towards clean water discharge. Their systems ensure water is clean, meeting North American standards. Freytech helps businesses stay green by following industry rules.

Requesting a Quotation or Site Assessment

Want to get an OWS system that works? Ask Freytech for a quote or site visit. They’ll show you their top-notch separators. These systems cut oil levels to meet rules. Working with Freytech helps your business go green and support global goals.