Could above ground separators change how you see maintenance in oil-water systems? Are Above Ground Separators Easier to Maintain? As we focus more on environmental rules, knowing if these separators are easier to maintain is key. They are great at removing oil and grease from water and offer many benefits over old models.

We will look into how these separators make maintenance easier. This can improve how well your system works, follow environmental laws, and avoid expensive repairs from ignoring maintenance.

Key Takeaways

- Above ground separators make it easier to check and maintain them.

- Cleaning them every six months is important for best results.

- Tasks include cleaning filters, checking levels, and removing sludge.

- Good maintenance can make oil separators last longer and follow rules.

- Regular checks catch small problems before they get big.

- Keeping a record of maintenance helps plan for the future.

- Following rules like MARPOL’s 15 ppm limit means you need to maintain well.

Understanding Oil Water Separators

Oil water separators (OWS) are key devices for removing oil and grease from water. They help protect the environment in many industries. Knowing the different types of oil water separators is important for businesses to find the right one.

What Are Oil Water Separators?

Oil water separators use the difference in density between oil and water to work. There are mainly two types: gravity separators and coalescing separators. Gravity separators let oil float to the top because it’s less dense. Coalescing separators use special media to combine small oil droplets into bigger ones, making removal easier.

Importance of Maintenance

Maintaining oil water separators is very important. Regular care keeps them working well and meets environmental rules. If you don’t maintain them, they can get clogged, reducing efficiency by up to 50%.

Ignoring maintenance can also lead to fines for not meeting oil removal standards. These standards are strict, like 10 PPM. Businesses should check their systems often and clean them to prevent problems. This way, they can avoid extra costs and harm to the environment.

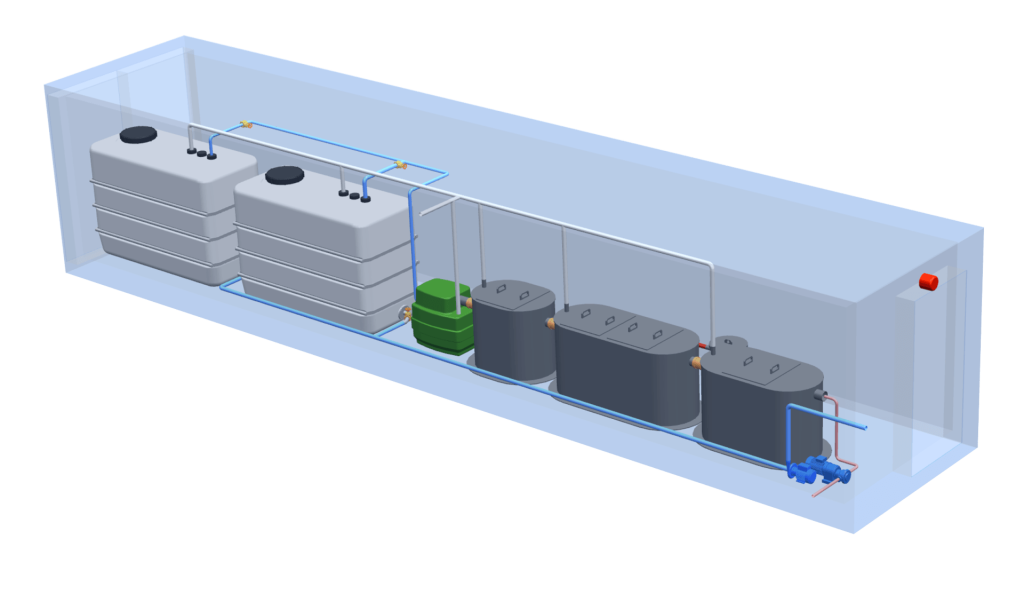

Advantages of Above Ground Separators

Above ground separators offer many benefits for different industries. One key advantage is their accessibility for maintenance. These systems make it easy to do routine checks, clean, and fix them. Unlike underground systems, you don’t need special gear or follow strict safety rules.

This makes maintenance quicker, cutting down on downtime. It’s a big plus for keeping operations running smoothly.

Accessibility for Maintenance

The design of above ground separators makes accessibility for maintenance better. You can get to the parts of the separator easily for regular upkeep. This simple maintenance helps avoid breakdowns and makes the separators last longer.

It also saves money and boosts efficiency. By making maintenance easier, facilities can run better and save on costs.

Reduced Environmental Impact

Another big plus of above ground systems is their reduced environmental impact. They help facilities meet strict rules on oil discharge. This protects the environment and keeps operations in line with laws.

Using these separators helps industries be more eco-friendly. For more on their benefits, check out this link.

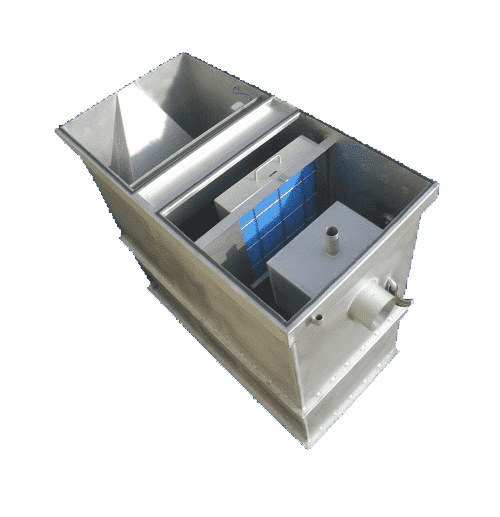

Freytech Inc. and Enhanced Coalescing Technology

Freytech Inc. is changing the game in oil water separation with its advanced coalescing tech. This tech uses special media that grabs small oil particles and turns them into big droplets. These big droplets then float to the top, making it easy to remove them.

How Does Enhanced Coalescing Work?

Freytech’s tech uses special plates in its separators. These plates are made to improve how oil and water separate. They catch even the tiniest bits of oil, making the system work better.

This means Freytech’s separators can get oil levels down to very low numbers. It’s a big step forward in keeping water clean.

Separation Efficiency Achieved

Freytech’s systems are really good at separating oil from water. They can get oil levels down to less than 5 PPM, even when they start with 2000 PPM. This is way better than what many other systems can do.

They meet or beat tough standards set by the CAN/ULC-S656 and the US EPA’s Clean Water Act. Some systems can even get oil levels down to 0.1 PPM. This shows that Freytech’s systems are not just meeting standards, they’re exceeding them.

Maintenance Features of Freytech Separators

Freytech separators have great maintenance features that make them very useful. They have reusable coalescing media. This feature cuts down on waste and keeps the separators working well for a long time.

Reusable Coalescing Media

Freytech separators use reusable coalescing media. This means they last longer and don’t cost a lot to replace. You can clean and use it again, which is good for the environment.

By cleaning it regularly, you can make sure the separators meet strict standards. They can keep oil levels below 5 PPM, helping you follow the rules.

Easy Spray Washing Process

The easy spray washing process is another great feature. It makes cleaning quick and easy, so you don’t have to stop work for long. This keeps your operations running smoothly and efficiently.

This process also helps save money. It makes Freytech separators a cost-effective choice for your needs.

Separation Efficiency Explained

Separation efficiency is key in many fields, like oil and gas. It’s about removing contaminants from water. A good separator can keep the water clean, meeting environmental standards.

Systems that focus on separation efficiency help a lot. They cut down the oil in water, making operations better.

Achieving 5 PPM and Below

Oil water separators aim for 5 PPM and below. This is a must for following rules. New technologies help remove more oil, keeping the environment safe.

Keeping these systems in top shape is important. Regular checks and modern designs help. This way, operations run smoothly and water is purified well.

What Is 0.1 PPM Separation Efficiency?

0.1 PPM is a top goal in the industry. It means almost all oil is removed from water. This is vital for places that send treated water back into nature.

Reaching 0.1 PPM needs advanced tech and careful work. It shows how important quality systems are for the planet.

Optional Features for Ease of Use

Freytech separators have many optional features to make them easier to use. These include a patented oil skimmer and an automatic oil drainage system. Both features help manage oil effectively.

Patented Oil Skimmer Functionality

The patented oil skimmer removes oil from the water’s surface. It sends the oil to a special container. This way, the oil is almost pure, with only 0.3% water.

This technology makes oil recovery easier. It saves time and effort for those who handle oil-contaminated water.

Automatic Oil Drainage Process

The automatic oil drainage system makes oil collection easy. It works without human help. This reduces mistakes and keeps the system running smoothly.

Adding these features helps companies manage their waste better. It also meets environmental standards.

Recycling and Environmental Benefits

Efficiently skimmed used oil is not just waste; it’s a valuable resource. It has significant recycling benefits from oil water separators. Proper management leads to effective recycling, reducing environmental harm and providing a profitable option for businesses.

Freytech’s technology ensures high recovery rates of used oil. This means less waste is lost during treatment processes.

Value of Efficiently Skimmed Used Oil

Used oil, when used correctly, can be reused instead of thrown away. This adds value to operations. Facilities using these systems often see a decrease in waste volume.

By using advanced oil water separation methods, companies meet environmental rules. They also gain financially by selling the recovered oils.

Cost-Effective Recycling Solutions

Businesses can cut costs by recycling efficiently. Regular maintenance of oil water separators reduces sludge and oil removal needs. This leads to lower costs for vendor services.

This approach brings economic benefits and supports environmental goals. It makes businesses more profitable while helping the planet.

Common Maintenance Practices

Keeping oil water separators in good shape is key for top performance and following environmental rules. Regular maintenance helps avoid breakdowns and protects the environment. It’s important for facilities to check and clean these separators often.

Routine Inspections

Regular checks are the first step in preventing problems with oil water separators. They help spot issues like leaks or blockages early on. Facilities should set up a schedule for these inspections, usually every three to six months.

These inspections look for things like sediment buildup and check if the equipment is working right. This ensures the separators work well and meet environmental standards.

Cleaning Procedures

Cleaning oil water separators is vital to keep them running smoothly. It involves removing oils, sediments, and sludge that build up. Most say to clean them every six months, but it depends on how much they’re used and local rules.

When cleaning, all water, oil, and sediment must be removed and disposed of properly. This helps the separators last longer and work better. It also keeps them within their design limits.

Compliance with Hydrocarbon Discharge Limits

Keeping hydrocarbon levels in wastewater under 10 PPM is key for industries in North America. This rule is set to protect the environment and public health. To follow this, companies need to use good wastewater treatment methods.

They must also check and lower oil and grease in their wastewater. Oil-water separators are very important for meeting these standards.

Understanding 10 PPM Regulations

It’s vital for businesses to follow hydrocarbon discharge limits. These rules help keep our environment and health safe. Advanced technology, like coalescing plate systems, helps remove hydrocarbons effectively.

These systems clean the wastewater well. This ensures it’s safe before it goes into the sewer system.

Why Choose Freytech for Compliance

Many ask why choose Freytech for oil-water separators. Freytech’s technology is top-notch, often beating the limits set by regulations. Their separators last a long time and need only occasional checks.

This means they work well and help avoid big fines. For more details, check out Freytech’s website.

Customer Success Stories

Freytech Inc. has many customer success stories. They show how Freytech’s separators boost performance and make maintenance easy. These stories prove their systems work well in real life.

Case Studies of Enhanced Performance

Many case studies show big improvements in performance for companies using Freytech’s separators. They see better operational efficiency and higher compliance rates. This shows the value of choosing Freytech technology.

These detailed studies also show Freytech’s dedication to quality and innovation. They highlight the company’s focus on making the best separator solutions.

Testimonials on Maintenance Ease

Customers often talk about how easy it is to clean and maintain Freytech separators. They find routine upkeep simple, which helps teams keep things running smoothly. This feedback shows how happy customers are with Freytech’s solutions.

It also proves that Freytech products are reliable over the long term. Users are very satisfied with their experience.

Reach Out to Freytech Inc.

Organizations interested in top-notch above ground separators can benefit from Freytech Inc.’s help. They offer expert advice and customer service. Whether you want to talk about your needs, learn about their products, or set up a meeting, Freytech’s team is here to help.

This dedication to helping clients matches the growth of the global industrial oil water separators market. It’s expected to hit USD 12.81 billion by 2023 and keep growing until 2030.

Contact Information

For quick answers about separators and advanced coalescing technology, contact Freytech Inc. They use innovative solutions that meet hydrocarbon discharge limits. This makes them stand out in the oil and gas field. Feel free to reach out for help with your operations.

Phone Number: +1 (305) 372-1104

Freytech’s phone number for inquiries is +1 (305) 372-1104. This direct line ensures clients get fast support. It shows Freytech’s commitment to excellent customer service.

With advancements in separation technology, Freytech can offer efficiencies as low as 0.1 PPM. They are ready to meet your separator needs.