Have you ever thought about if Are Below Ground OWS Systems Effective? or how much oil and water mix in places like factories or car shops? Below ground oil water separators are being talked about a lot. They are meant to clean up oily wastewater. But do they really work well?

These systems are designed to meet tough environmental rules. Companies like Freytech Inc. are making these systems better. But do they make a big difference in keeping our environment clean and avoiding big fines for businesses?

Key Takeaways

- Below ground oil water separators can effectively reduce oil levels to below 5 PPM.

- These systems are key for following the US EPA’s Clean Water Act standards.

- Freytech’s new tech can catch tiny oil particles down to 0.1 PPM.

- Putting these systems in place needs careful following of local rules.

- They can handle up to 1000 Imperial gallons of wastewater per minute.

- Keeping them running right means regular upkeep, like cleaning filters.

Understanding Below Ground OWS Systems

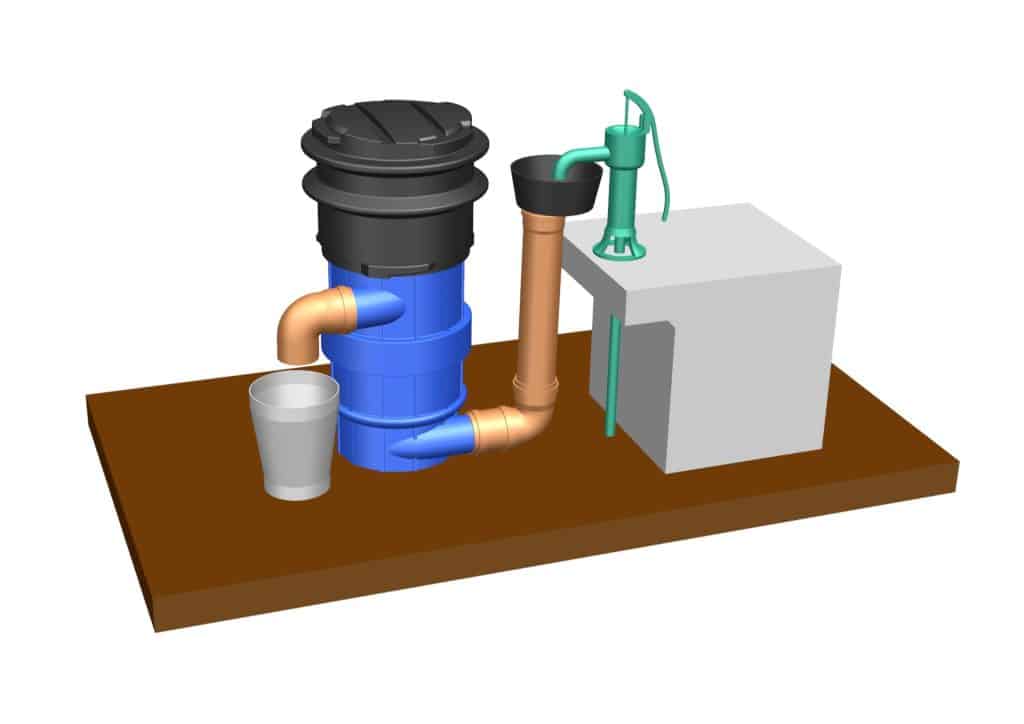

Oil water separators (OWS) are key to keeping our environment safe. They remove harmful substances from oily water. Knowing how they work is vital for companies that need to follow environmental laws.

These devices, often hidden underground, separate oil, grease, and other harmful substances from water. This prevents them from polluting our natural water sources.

What is an Oil Water Separator?

An oil water separator is a system made to clean oily water. It’s common in industrial and maritime settings. It uses methods like gravity, coalescing, or centrifugal separation to remove oil.

The process happens in several stages. This ensures the water is clean enough to be safely released. For example, the OWS must keep oil content below 15 parts per million (PPM). This follows rules like MARPOL Annex I.

How Below Ground Systems Operate

Below ground systems work well by collecting oily water in a tank. The oil, being lighter, floats on top of the water. This is because oil is less dense than water.

These systems have special designs, like multiple chambers, to improve oil separation. Keeping them well-maintained is important. It helps them meet discharge limits and work at their best.

Importance of Hydrocarbon Discharge Limits

Hydrocarbon discharge limits are key to protecting our environment, mainly in North America. They help control the amount of harmful substances in our water. This keeps our water bodies healthy and our ecosystems balanced.

Companies must follow these strict rules to avoid fines. It also helps keep our planet stable.

Overview of North American Standards

In North America, we have rules to keep our water clean. The goal is to have no more than 10 parts per million (PPM) of hydrocarbons in treated water. This is a must for industries that handle wastewater.

If they don’t meet these standards, they face big fines. It also hurts their reputation.

Compliance with 10 Parts per Million

Meeting the 10 Parts per Million standard is more than a rule. It’s a promise to care for our planet. Companies using the latest tech, like Freytech Inc., can do even better.

These systems can separate more efficiently than required. This shows top-notch OWS performance. It helps businesses be green while staying strong.

Advanced Separation Technology by Freytech Inc.

Freytech Inc. has developed a cutting-edge solution for wastewater management. Their advanced separation technology uses enhanced coalescing technology. This is a big step forward in oil water separation, which is key in industrial settings.

This technology combines small oil droplets into bigger clusters. This makes it easier to separate oil from water mixtures.

Enhanced Coalescing Technology Explained

The heart of Freytech’s technology is its enhanced coalescing method. It boosts OWS efficiency by using special media that helps oil droplets stick together. Variables like droplet size, distance, and flow rate are adjusted to improve separation.

This optimization helps industries meet strict environmental rules. It ensures they can handle their wastewater effectively.

Achieving 5 PPM Separation Efficiency

Freytech’s systems can separate oil from water at incredibly low levels, down to 5 PPM. This makes them a top choice for reliable oil water separation solutions. They help various industries, from oil refineries to steel mills, manage their wastewater.

This focus on 5 PPM separation efficiency supports environmental goals. It helps these industries meet sustainability standards.

Maximizing Performance with Coalescing Media

Freytech’s reusable media is a game-changer for improving oil-water separation in underground systems. It’s made for lasting use and helps the environment. With a huge coalescing surface area, these systems work well even when flow rates change.

Features of Freytech’s Reusable Media

The media’s design has 3/16 inches of space between elements. This setup removes 99.9% of oil droplets over 20 microns. It also has 87% void volume for settling solids, keeping oil out.

Maintenance for Long-Term Use

Keeping Underground OWS systems in top shape is key. Regular cleaning and checking of solids chambers are musts. Watching system performance and following environmental rules is also important. Following these steps keeps Freytech’s media working well for a long time.

Trace Oil Separation Capabilities

Freytech’s systems lead in trace oil separation, making them stand out in the oil-water separator (OWS) field. They can separate emulsified oil down to 0.1 PPM, a remarkable achievement. This is key for industries under tight environmental rules.

Achieving 0.1 PPM Separation Efficiency

Freytech’s systems are designed to catch even the smallest oil amounts with great accuracy. They can isolate oil down to 0.1 PPM, reducing hydrocarbon contamination in water. This meets and goes beyond legal standards, improving water quality.

Importance for Environmental Compliance

Environmental compliance is critical today. With water pollution on the rise, industries must follow strict hydrocarbon discharge limits. OWS performance shows how important it is to keep water quality high. This protects our water resources and shows a commitment to the environment.

Benefits of Using Freytech Oil Skimmer

The Freytech oil skimmer offers many benefits, mainly because of its new way of removing oil. It uses an automated and mechanical draining process. This makes operations more efficient.

This system allows for continuous oil skimming without manual help. It also meets water quality standards.

Automated and Mechanical Draining Process

The Freytech oil skimmer’s automated and mechanical draining processes improve oil removal. It can remove hydrocarbons as low as 0.1 parts per million. This meets federal discharge limits and shows great performance.

It also offers customization for separator tanks. This makes it suitable for facilities needing a flow rate of 1 to 100 gallons per minute. It’s perfect for many industrial uses.

Purity of Skimmed Oil

The purity of skimmed oil is a key advantage of Freytech systems. They can achieve purity levels of 99.7%. This means the oil is almost free from water impurities.

This high quality makes the oil better for recycling. Following best practices for OWS installation ensures these systems work well. This is important in places with strict environmental rules.

Recycling and Economic Value of Separated Oil

Efficiently skimmed used oil is now a valuable resource, bringing big economic benefits to many industries. Companies using Freytech’s technology can recycle oil well, turning waste into something useful. The recycling and economic value of separated oil is key for businesses, helping them save money with high-quality oil recovery.

The Value of Efficiently Skimmed Used Oil

The market demand for efficiently skimmed used oil boosts profits for many companies. By collecting this valuable oil, businesses cut down on waste and can sell the oil, improving their finances. This practice has a positive effect on both the economy and the environment. Learning about recycling at no cost encourages businesses to manage waste better.

Recycling Process at No Cost

The recycling process made possible by Freytech’s oil water separators costs companies nothing. This green approach not only helps the environment but also fits with the global shift towards circular economies. Good waste management lets companies follow underground OWS maintenance tips for better operation and oil recovery, all while helping the planet.

Comparing Below Ground and Above Ground OWS Systems

Below ground and above ground oil water separator (OWS) systems have big differences. They vary in efficiency, environmental impact, and how much upkeep they need. Knowing the benefits of below ground systems helps choose the best option for each situation.

Advantages of Below Ground Systems

Below ground OWS systems have many benefits. They can remove up to 95% of hydrocarbons from wastewater. This high efficiency helps keep the environment clean, which is important for industries with strict rules.

These systems are also safer. They have a spill risk under 5%, while above ground systems can have a risk of up to 20%. The earth protects them, keeping temperatures steady and making them last longer.

Situational Considerations

Deciding between below ground and above ground OWS systems depends on several factors. Land use, available space, and local laws are key. In cities with little outdoor space, below ground systems save room and look better.

When installing, think about the underground design. This includes how deep and big the tank needs to be. Maintenance is also important; below ground systems need checks every 6 to 12 months. Above ground systems might need checks every 3 to 6 months. Looking at all these factors helps pick the right OWS system for the job.

Conclusion: Effectiveness of Below Ground OWS Systems

Below ground oil water separator (OWS) systems are very effective. They keep water clean and meet strict environmental rules. These systems use advanced tech to remove oils from water, helping prevent pollution in many industries.

They work by using the fact that oil is less dense than water. This makes them very good at separating oil and water. It also saves money and reduces the chance of fines for not following environmental rules.

Summary of Key Benefits

Underground OWS systems have many benefits. They use new tech like advanced flocculation and coalescing plates to improve separation. Regular upkeep and monitoring systems help keep them running well.

These systems also take up less space. This makes them perfect for places like marine, automotive, and petroleum industries where space is limited.

Contact Freytech Inc. for Expert Solutions

If you want to improve your below ground OWS system or upgrade, contact Freytech Inc. They focus on making systems work better and follow rules. This helps manage wastewater in a green way.

Call Freytech Inc. at +1 (305) 372-1104. They can offer custom solutions to fit your needs and improve the environment.