Is your restaurant unknowingly causing sewer backups and harming the environment with bad FOG management? Fats, oils, and greases (FOG) are big by-products of food prep. If not managed right, they can cause expensive plumbing problems and break rules. It’s key to know and use good FOG removal methods to keep your kitchen clean, efficient, and in line with the law.

We’ll share seven tips for better FOG removal and treatment in the food world. These tips focus on being proactive with FOG control. They can lower costs for sewer upkeep and make sure you follow local rules. Plus, they help your place be more eco-friendly.

Key Takeaways

- Understanding FOG and its sources is key for good management in food service.

- Keeping grease traps in good shape is vital to avoid expensive plumbing troubles.

- Teaching employees how to dispose of FOG properly can greatly cut down environmental risks.

- Using new grease management solutions can boost compliance and make things run smoother.

- Following local rules can prevent big fines and keep your business running smoothly.

Understanding FOG and Its Impact on the Food Industry

FOG stands for Fats, Oils, and Greases. It comes from food prep in commercial kitchens. It includes animal fats and vegetable oils, which are lighter than water.

Removing and controlling FOG is key. It prevents environmental risks and plumbing problems.

What is FOG?

FOG is made during food processing and prep. It can clog sewer systems if not disposed of right. This can cause pipes to shrink, leading to high costs and health risks.

It’s important to manage FOG to protect the environment and infrastructure.

Common Sources of FOG in Food Processing

FOG comes from cooking oils, dairy, meat fats, and saucy condiments. More restaurants and food courts mean more FOG. If not handled, it can block sewage systems.

This causes problems for businesses and the environment.

Regulatory Implications of FOG Discharge

FOG discharge has strict rules in many places. Food Service Establishments must use grease removal devices and follow best practices. Breaking these rules can result in fines or shutdowns.

Untreated FOG can also raise costs for everyone. Managing FOG is critical for following rules, keeping people safe, and protecting the environment.

Best Practices for FOG Prevention

Keeping plumbing systems in the food industry working well is key. Regular maintenance and training programs for employees help a lot. They cut down the risk of grease clogging in traps and interceptors.

Routine Maintenance and Cleaning Protocols

Grease traps need cleaning every 30 days to work right. If there’s too much grease, they must be cleaned more often. Grease interceptors should be emptied and cleaned every 90 days, or sooner if they get too full.

Checking grease devices weekly is important. It makes sure they’re working and avoids expensive sewer overflows. Keeping records of maintenance is also vital. It shows when cleaning was done, who did it, how much grease was removed, and where it was thrown away.

Following these steps is not just about following rules. It’s also smart for the business’s wallet.

Employee Training and Awareness

It’s important to teach staff about FOG Prevention. They should learn how to scrape plates before washing and how to dispose of cooking oils correctly. Knowing about Grease Interceptor Maintenance helps everyone manage waste better.

This knowledge helps avoid problems like overflow and blockages. Sharing what they know with each other makes everyone more responsible. It’s good for the environment and helps the business too.

Implementing Effective FOG Removal Technologies

Effective FOG Treatment needs advanced technologies to separate and manage fats, oils, and grease. Oil Water Separators (OWS) are key in this process. They help tackle the challenges FOG brings to wastewater systems, mainly in food processing.

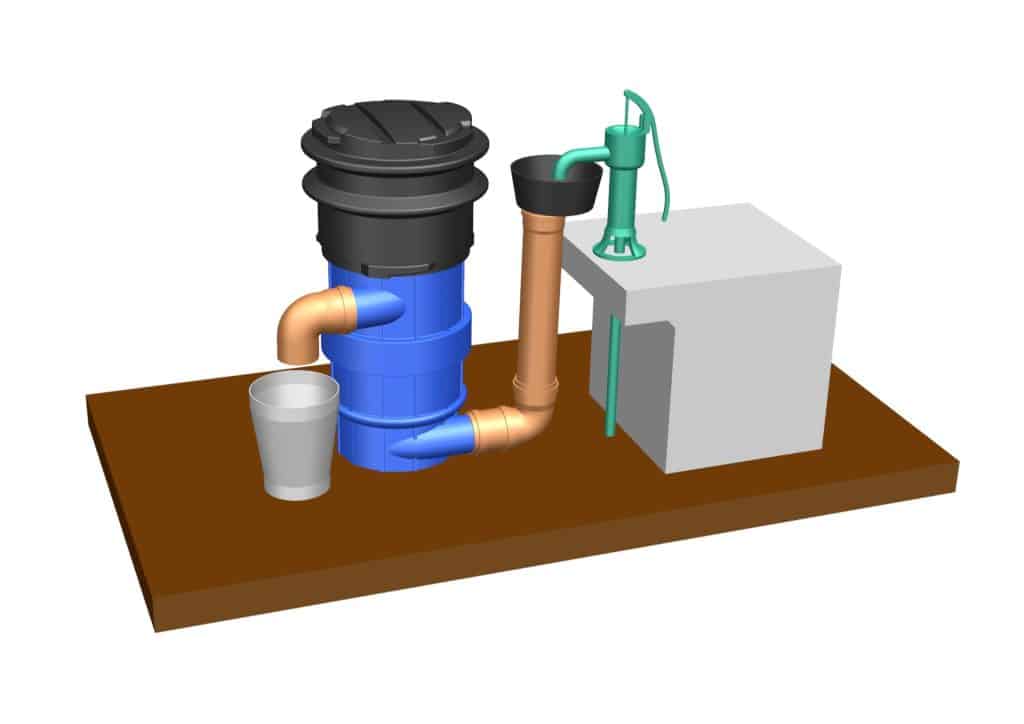

Overview of Oil Water Separators

Oil Water Separators are vital for removing oil, grease, and other hydrocarbons from water. They stop FOG from getting into wastewater systems. This helps avoid flow problems caused by too much fat and oil.

These systems work well in places like restaurants and food factories. There, FOG can cause big problems.

Features of Enhanced Coalescing Technology

Advanced systems with enhanced coalescing technology work better in FOG Control. This new method improves how oil droplets are separated. It leads to cleaner water going into treatment systems.

Enhanced coalescing is more efficient than regular Oil Water Separators. It helps keep FOG levels low, meeting environmental standards. This is good for the environment.

The Role of Freytech Inc. in FOG Management

Freytech Inc. is key in FOG Management for the food industry. They use advanced tech and focus on sustainability. This helps solve grease disposal issues in commercial kitchens.

Their solutions meet strict North American rules and make grease removal more efficient. This leads to lower costs and better productivity for food places.

Innovative Solutions for Effective FOG Removal

Freytech Inc. offers top-notch solutions for grease in kitchens. Their tech can catch up to 95% of grease, cutting down on environmental harm and costs.

By managing FOG, businesses can save on grease trap upkeep and sewer bills. They can also see a 50% boost in work efficiency with the right systems.

Case Studies Demonstrating Success

Many case studies show Freytech’s systems work well in the food service world. Clients have seen big drops in upkeep costs and fines for not following rules.

Places working with Freytech also see fewer sewer blockages. This shows that 75% of such problems can be prevented with good FOG management. The success stories prove Freytech’s leading role in the field.

Ensuring Compliance with North American Regulations

In the food industry, following FOG Compliance rules is key. It keeps licenses and protects public health. Businesses must stick to 10 Parts per Million (PPM) FOG limits. Not doing so can lead to big fines or even closure.

Understanding 10 PPM Discharge Limits

The 10 PPM FOG limits help keep sewer systems and the environment safe. Local authorities check food places to make sure they follow these rules. They look at maintenance records and grease control systems.

If a place doesn’t follow the rules, they might face penalties. This could include notices and even criminal charges under environmental laws. It’s very important to know about local rules.

How Freytech Achieves 5 PPM Separation Efficiency

Freytech uses advanced technology to get 5 PPM separation efficiency. This tech goes beyond what’s required and cuts down FOG levels. By using good grease traps and keeping them clean, businesses can meet FOG standards.

Benefits of Using Freytech Oil Water Separators

FOG Removal is key in the food industry. It deals with fats, oils, and greases in wastewater. Freytech Oil Water Separators solve these problems, making maintenance easy and improving efficiency.

High Efficiency and Reusability of Coalescing Media

Freytech’s coalescing media is top-notch at separating oil from water. It has high efficiency rates for FOG removal. This technology is reusable, cutting down on costs and supporting sustainability.

By using these systems, businesses can greatly reduce waste disposal costs. They also save on downtime. This leads to big savings and helps meet environmental standards.

Automatic Oil Skimming for Easy Maintenance

Freytech units have an automatic oil skimming feature. It makes maintenance easy by removing oil from the chamber. This reduces the need for manual work.

With this system, facilities can run smoothly without constant maintenance checks. They can focus more on their main tasks. For more details, check out Freytech Oil Water Separators.

Environmental Considerations in FOG Disposal

Proper disposal of FOG is key in the food industry. Improper disposal of fats, oils, and grease can cause big problems. These include clogged pipes and higher maintenance costs for homes and cities.

Sewer backups from FOG harm homes and businesses. They also hurt local infrastructure and ecosystems.

Impact of Improper FOG Disposal

Improper FOG disposal harms the environment a lot. It leads to untreated wastewater and increases contamination risks in waterways. FOG can block sunlight and lower oxygen levels, harming plants and animals in water.

It can also coat fish gills, causing suffocation and disrupting food chains. Over time, FOG can create big blockages in sewers. This causes pollution and destroys habitats, threatening biodiversity.

Recycling Opportunities for Skimmed Oil

Recycling skimmed oil turns waste into valuable resources. It can be made into biodiesel and other products, helping the environment. The Town of Lincoln gives out biodegradable FOG collection cups to residents.

This helps with proper disposal and reduces costs and sewer blockages. It also lets the community help reduce environmental harm.

Troubleshooting Common FOG Issues

Dealing with FOG problems is key for the food industry’s smooth operation. Finding out where high FOG levels come from helps businesses tackle the issue. Regular checks are important to spot trouble spots early.

Identifying Sources of High FOG Levels

Effective FOG management starts with knowing what causes high levels. Cooking oils, food waste grease, and cleaning runoff are common culprits. Knowing these helps businesses create better prevention plans.

Steps for Immediate Response

When high FOG levels are found, quick action is needed to prevent long-term issues. Cleaning grease traps and tweaking how things are done can quickly reduce FOG. Training staff on these steps helps lower risks and keeps things in line with rules.

The Future of FOG Management in Food Processing

The way we manage FOG in food processing is changing fast. New technologies and practices are coming in. Companies must handle waste well and follow strict rules.

As more places see the need for better systems, we’ll see more automation and green practices. This will shape the future of FOG management.

Emerging Technologies and Innovations

New tech like bioremediation and automated grease systems are changing the game. They help catch and reuse fats, oils, and grease. This stops blockages and protects the environment.

Using grease traps and interceptors keeps FOG out of drains. This cuts down on problems and makes our environment cleaner.

Long-term Benefits of Effective FOG Strategies

Good FOG strategies avoid fines and help the planet. Turning used cooking oil into biodiesel is a great example. It shows how smart management can help the environment.

By watching FOG levels and following rules, businesses get big benefits. They keep their kitchens clean, improve health, and attract green customers. This makes them stand out in the food industry.

For more on effective solutions, check out Freytech’s oil water separators. They’re great for managing FOG.

Contact Freytech Inc. for Expert Assistance

If your business is struggling with FOG management, Freytech Inc. can help. We offer customized solutions to fit your needs. Call us at +1 (305) 372-1104 to speak with our team.

We focus on making sure you meet all regulations. We also help reduce FOG’s impact on your business. This way, you can run smoothly and efficiently.

How to Reach Us

At Freytech, we put your needs first. Our team is here to help with all your FOG management questions. We’ll guide you on the best ways to handle grease traps and follow regulations.

Need advice or just want to learn more? Freytech support is always ready to assist you. Just give us a call.

Additional Resources for FOG Solutions

Besides direct help, Freytech offers lots of educational materials. These resources give you the tools to manage FOG effectively. They help you stay up-to-date with regulations and adopt sustainable practices.

With our knowledge, you can tackle FOG challenges head-on. Protect your facilities and keep your business running smoothly.