Ever thought about How do Below Ground Separators Compare to Above Ground Ones? When it comes to oil-water separation technologies, a key question is: Are below ground separators better than above ground ones? Industrial sectors like mining, steel, and power generation need to treat wastewater with oil. Knowing the differences between these separators is vital.

Both types use gravity to separate oil and water. But they have their own benefits and drawbacks. This article explores the world of separators to help you choose the right one for your needs. It also looks at environmental rules and how to work more efficiently.

Key Takeaways

- Below ground separators save space and look better than above ground ones.

- Both types use gravity, but below ground ones are better for the environment.

- Coalescing oil-water separators can greatly improve oil recovery in many situations.

- Above ground separators are easier to get to for maintenance and checks.

- The right choice between below ground and above ground separators depends on your site and needs.

Understanding the Basics of Oil Water Separators

An oil water separator is a device that removes oil, grease, and other hydrocarbons from water. It plays a key role in managing wastewater. It’s important for industries like manufacturing, shipping, and oil extraction to follow environmental rules.

What is an Oil Water Separator?

Oil water separators treat wastewater by separating oil from water. They use different methods to do this. These systems handle various oil types and amounts, making sure the water is clean before it’s released.

The success of these systems depends on the type used and its design. This is tailored to fit specific needs.

Purpose and Functionality

The main goal of oil water separators is to make sure wastewater is clean before it’s released. This helps industries save money on water disposal and avoids fines. Thanks to new technologies, these systems can remove contaminants very effectively.

This is important for protecting the environment.

Types of Oil Water Separators

There are many types of oil water separators, each for different methods. Gravity-based separators are affordable but may not work well with small oil droplets. Coalescing separators, on the other hand, are great at removing small droplets, achieving over 90% efficiency.

Other types, like API separators and centrifugal separators, handle high flow rates and emulsified oils. Knowing about these types helps choose the right one for different needs.

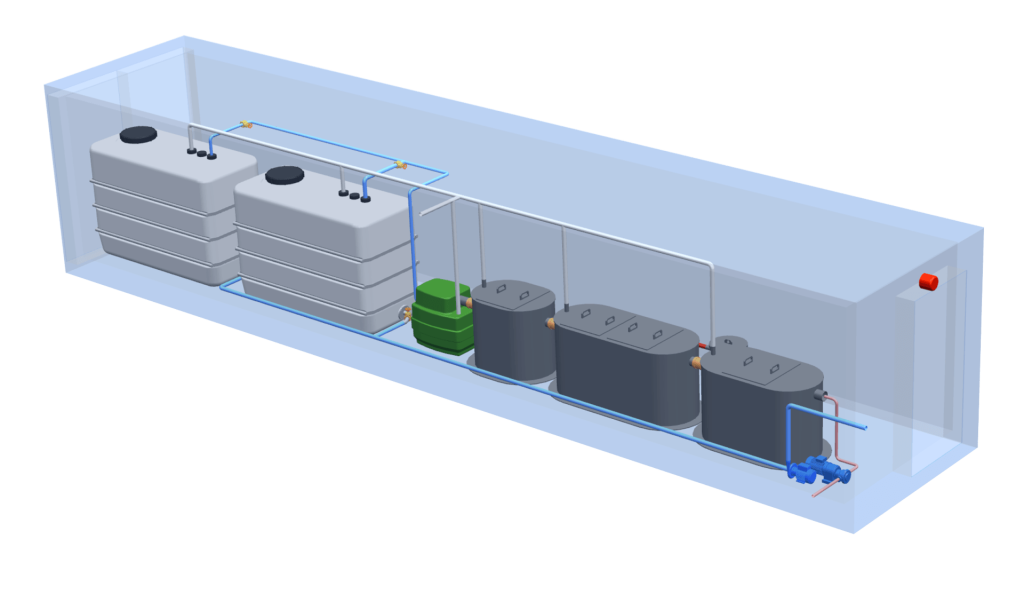

Below Ground Separators: Features and Benefits

Below ground separators have many benefits for different uses. They are designed to fit in tight spaces, making them great for cities. These systems can separate oil, gas, and water without messing up the surface.

Space Saving Advantages

In crowded cities, the space-saving feature of below ground separators is a big plus. They can be installed underground, saving space on the surface. This is key for cities where every inch counts, allowing for better use of space.

Reduced Environmental Impact

These separators have a lower environmental impact than old systems. They manage stormwater runoff well, cutting down on oil spills. This helps protect local ecosystems from harm.

Enhanced Aesthetic Appeal

Freytech’s below ground separators also make places look better. They don’t take up surface space, keeping landscapes open and nice. This not only looks good but also makes properties more valuable.

Above Ground Separators: Features and Benefits

Above ground separators have many advantages. They make it easy to access them for maintenance and checks. This means you can do inspections without digging, saving time and money.

Accessibility for Maintenance

These separators are easy to get to for upkeep. Regular checks keep them running well. They need to be serviced every 3-6 months, depending on how much sludge builds up.

This helps keep them working efficiently and avoids expensive downtime.

Versatility in Installation

These separators are easy to set up in different places. They can handle flow rates from 1,000L to 5,000L per hour. This makes them flexible for various uses.

Visibility and Security Concerns

But, there are also challenges. Exposed systems might need extra safety to stop tampering or vandalism. It’s important to keep them in good shape and follow environmental rules.

Performance Efficiency: Below Ground vs. Above Ground

Oil-water separators are key for industries dealing with oily wastewater. Below ground separators outperform above ground ones, removing up to 99% of oil. Freytech leads, ensuring a discharge as clean as 5 Parts per Million (PPM), beating the North American limit of 10 PPM.

Separation Efficiency Explained

Knowing about separation efficiency is vital for those following environmental rules. Below ground separators handle oils with specific gravities well, removing contaminants effectively. Freytech’s tech can separate to 0.1 PPM, removing even refined hydrocarbons like motor oil and diesel.

Freytech’s 5 PPM Guarantee

Freytech’s 5 PPM guarantee shows their dedication to quality. Places like mechanical workshops, car washes, and gas stations use these to meet the US EPA’s Clean Water Act. These separators last 15-20 years, proving they’re a wise choice for eco-friendly practices.

Achieving Trace Separation at 0.1 PPM

Reaching 0.1 PPM separation shows the tech leap in separation methods. It also shows the perks of using Freytech solutions. These systems are great for places where water pollution must be kept low. They can cut carbon emissions by 25% compared to old systems. For more on these technologies, check out Freytech’s website.

Maintenance Considerations for Below Ground Separators

Maintaining below ground separators comes with its own set of challenges. Getting to the parts for checks or fixes can be hard and costly. It often means digging, which adds to the time and effort needed.

Keeping an eye on how well these separators work is key. It helps make sure they meet environmental rules. Taking good care of these systems is important for their long life and performance.

Challenges in Accessing Components

Getting to the parts of below ground systems for upkeep is tough. The parts are deep underground. This can lead to higher costs and longer breaks for maintenance.

It’s smart to plan ahead for maintenance. Regular checks help keep the system running smoothly.

Long-Term Care and Longevity

Looking after below ground separators for the long haul is important. Regular upkeep keeps them working well and meets legal standards. It also helps them last longer.

Research shows these systems can last up to 25 years. That’s much longer than some above ground systems.

Freytech’s Reusable Coalescing Media

Freytech’s reusable coalescing media makes maintenance easier. It can be cleaned with a spray wash, lasting for years. This makes water separation more efficient.

It also means less time spent on maintenance. This helps keep the system running smoothly for a long time.

Maintenance Considerations for Above Ground Separators

Above ground separators make maintenance easier. Their design lets you access them for checks and repairs without hassle. This means you can spot problems quickly and fix them fast, saving time and money.

Ease of Access for Routine Checks

Keeping up with regular maintenance is key for these separators. They need cleaning every six months, or more often if needed. It’s important to check them regularly for any signs of trouble.

By keeping filters and screens clean, you avoid clogs. This keeps the system running smoothly. Remember, a clean system is a happy system.

Repair and Replacement Insights

Having a maintenance plan is essential for repairs. Keep a record of all maintenance work. This helps you track how well your system is doing.

Using professional maintenance services can add 20% to your equipment’s life. With the right tools, you can fix small problems before they get big. This makes your maintenance routine more reliable.

Environmental Compliance and Regulations

In the oil-water separation industry, keeping the environment safe is key. North America has rules that say facilities can’t have more than 10 PPM of hydrocarbons. Following these rules is not just a suggestion; it’s the law for places that handle hydrocarbon discharges.

North American Hydrocarbon Discharge Limits

Places that started building, changing, or fixing up after September 18, 2015, have to meet strict rules. They must watch how much greenhouse gases and VOCs they release. This includes checking emissions from big storage tanks that can release 6 tons a year or more. Taking these steps helps protect the environment and keeps it clean.

Freytech’s Commitment to Clean Discharge

Freytech is all about doing things right for the environment. They use top-notch tech to keep emissions under 5 PPM. This not only cuts down on harm to the environment but also makes Freytech a top name in green operations.

The Importance of Regulation Adherence

Following environmental rules is vital to avoid big fines and damage to reputation. Facilities need to be ready for things like floods and sea level rise, as suggested by the Maine Climate Council. By sticking to these rules, companies help keep the environment safe and protect communities.

The Role of Coalescing Technology in Performance

Coalescing technology is key to making oil water separators work better. It uses special media to help small oil droplets grow into bigger ones. These bigger droplets then float to the top, making it easier to remove them.

Freytech’s advanced coalescing media has more surface area. This means it can separate different types of refined hydrocarbons more efficiently.

How Coalescing Media Works

Coalescing media works by sticking small oil droplets together. When oil water mixtures go through these separators, the droplets merge. This creates bigger droplets that are easier to remove.

This process is vital for getting oil out and keeping our environment clean. The special surface of the media helps it work better, making it essential for industrial use.

Benefits of Enhanced Coalescing Technology

Coalescing media does more than just work well. It also helps keep our environment safe by cutting down oil pollution. This makes oil-water separation processes more eco-friendly.

Using advanced coalescing technology in separators saves money and boosts performance. It shows why it’s so important in many industries.

Oil Skimming Technology: A Closer Look

Oil skimming technology is key in efficient oil-water separation systems. It’s vital in many areas, from small operations to big spill responses. The patented oil skimmer from Freytech works well in calm and rough waters. It’s reliable in pulling oil out of water.

Function of the Patented Oil Skimmer

The patented oil skimmer automatically pulls out oil. It makes sure a lot of waste oil is removed. Its design helps it work well even in tough conditions.

This makes oil-water separators more effective. It helps meet important environmental rules.

Quality of Skimmed Oil: 99.7% Purity

The skimmed oil is very pure, at 99.7%. This high-quality oil is great for recycling and lowers waste oil’s environmental harm. Some think one pass is enough for oil removal. But, skimmers often need more passes for the best results.

Environmental and Economic Benefits of Skimmed Oil

Oil skimming has big environmental and economic pluses. It cuts down on oil contamination risks for nature. It also saves money by avoiding fines and damage costs.

It can handle more than just petroleum, like food oils and grease. This makes it useful in many fields. Companies using oil skimmer tech help the planet and improve their image.

Making the Right Choice for Your Needs

Choosing the right separator depends on several factors. The type of site and its needs are key. Consider space, environmental rules, and how easy it is to maintain the area.

Knowing these details helps match the separator to your site’s needs. This ensures it works well and efficiently.

Factors to Consider: Site and Application

Think about what your operation needs most. The choice between a below or above ground separator often depends on your site’s layout. Below ground saves space and looks better, but above ground is easier to maintain.

Looking at these points helps pick the best system for your site. It makes sure your separator works well in your unique situation.

Cost Effectiveness and Long-Term Benefits

Cost is a big part of choosing a separator. Even though some models cost more upfront, they last longer and need less upkeep. This can save money in the long run.

Following environmental rules is also important. It avoids fines and helps the planet. Choosing a separator that balances cost and longevity is wise. It saves money over time.