Ever thought about How to Install a Below Ground Oil Water Separator? or how businesses handle oily wastewater and follow environmental rules? Installing a below ground oil water separator is key. This guide will show you how to install one, highlighting their role in treating oily wastewater. It’s important for meeting legal standards.

For example, separators that meet North American standards can greatly reduce environmental harm. With solutions like Freytech’s, which can reach 0.1 PPM efficiency, knowing how to install is vital.

Key Takeaways

- Understanding the importance of oil water separators for managing oily wastewater.

- Learn the installation steps to ensure compliance with regulations.

- Selecting the right separator based on site-specific needs.

- Routine maintenance tips to maximize separator efficiency.

- Common troubleshooting methods for effective problem resolution.

Understanding Oil Water Separators

Oil water separators are key devices that separate oil, grease, and other hydrocarbons from water. They are designed to protect the environment and meet regulations. Understanding these separators is important for industries and their benefits.

What is an Oil Water Separator?

An oil water separator uses gravity and coalescence to separate oil from water. This makes it possible to treat contaminated water before it’s released. Knowing about these separators is vital for businesses to avoid fines.

Importance of Using a Separator

Using a separator is very important for industries with oily wastewater. It can save over $100,000 in fines and cut disposal costs by 50%. Regular upkeep keeps systems running efficiently and safe for the environment.

Applications of Oil Water Separators

Oil water separators are used in many fields like automotive, manufacturing, aviation, and marine. Each industry needs specific techniques for different wastewater volumes and oil levels. For instance, auto repair shops use them to meet strict discharge limits, showing their effectiveness in protecting water resources.

Selecting the Right Separator

Choosing the right oil water separator is key for top performance and meeting environmental rules. Several factors are important, like flow rate, space needs, and upkeep. Knowing these can greatly affect both how well it works and its cost.

Factors to Consider

Flow rates are a big deal when picking a separator. Horizontal ones are great for big flows, like in oil and gas. They take up more space, often over 10 feet long.

On the other hand, vertical separators are better for tight spaces, being about 5 feet tall. They cost less upfront but might not handle as much. This is something to think about.

Benefits of Freytech Enhanced Coalescing OWS

Freytech Enhanced Coalescing Oil Water Separators are top-notch. They use advanced tech to separate oils well, including motor oil and diesel. They keep water quality high, with less than 5 PPM of light liquids.

They last a long time, up to 100 years, and come with a 25-year warranty. This means less upkeep and more reliability. You can learn more here.

Comparing Separation Efficiencies

It’s important to compare how well different separators work, mainly for places with strict rules. Freytech’s tech is great at catching small oil droplets, meeting European standards.

Looking at how different models remove pollutants and solids helps make better choices. The wrong choice can cause big problems and costs, over $10,000 an hour. So, picking the right one is critical.

Pre-Installation Procedures

Before starting the installation of a below ground oil water separator, it’s important to know the necessary steps. Each step is key to making sure the project follows local laws and meets environmental standards.

Site Assessment and Planning

Doing a thorough site assessment is vital when planning to install an oil water separator. It’s important to check the environment and space available. This helps find the best spot for the unit and makes the installation smoother.

Necessary Permits and Regulations

Getting the right permits is essential to follow local rules for installing oil water separators underground. Knowing these rules helps avoid delays and ensures the project meets all legal requirements.

Required Tools and Equipment

Having the right tools ready before starting the project makes things easier. You’ll need things like excavation gear, concrete forms, and materials for pipes and valves. Being prepared helps keep the work safe and on track.

Preparing the Installation Site

Getting the installation site ready is key for the success of below ground oil water separators. It’s important to meet excavation needs. This ensures the right size and depth for the separator. Good planning here is the base for the whole system.

Excavation Requirements

When excavating, think about the separator’s size and extra space for maintenance. The depth must fit the separator and any underground systems. Proper digging avoids problems during and after setup.

Ensuring Proper Drainage

Good drainage is essential for the separator’s long-term work. Bad drainage can cause flooding or backflow, hurting the system. So, it’s important to grade the site and add drainage lines to avoid issues.

Handling Utility Lines

When setting up the site, be careful with utility lines. Find and mark existing lines to avoid damage. Following safety rules is not just smart but also required by law. It saves money and keeps services running smoothly.

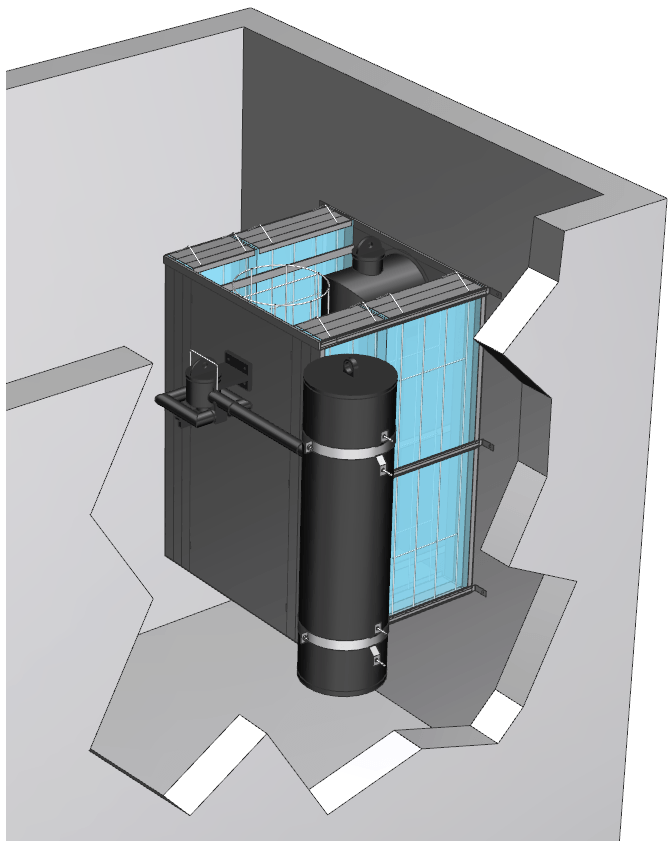

Installation Steps

The installation of an oil water separator is a detailed process. It involves important steps to ensure it works well. Each step is designed to help it perform at its best and meet legal standards.

Positioning the Separator

Choosing the right spot for the separator is key. It should meet drainage needs and stay away from contaminants. Make sure there’s enough room for upkeep and follow local rules.

Connecting Inlet and Outlet Pipes

Connecting the pipes needs to be done carefully to avoid leaks. Pipes must be aligned right to keep wastewater flowing smoothly. Use strong materials to handle different substances and last longer.

Installing Necessary Valves

Valves are essential for controlling water and oil flow. They also help during maintenance by isolating parts of the separator. Choosing good valves is important for a reliable and efficient system.

Connecting to the Drainage System

Connecting well to the drainage system is key for an oil water separator to work right. Following local rules is important to keep everything safe and running smoothly. Knowing these rules helps avoid fines and keeps operations green.

Compliance with Local Regulations

When you connect to the drainage system, following local rules is a must. These rules cover how to install, what materials to use, and how to maintain oil water separators. Following these guidelines helps you meet legal standards and makes your system more efficient.

Importance of Proper Sloping

Proper sloping is critical for good drainage flow and water level control. A slope of at least 1mm fall for every 80mm of trench length is recommended. This slope helps prevent water from staying in one place and keeps the separator working well.

Verifying Connections

Checking connections is vital to stop leaks and keep the system running right. Make sure all connections are tight, paying extra attention to areas that might weaken over time. Regular checks and upkeep help spot problems early, keeping the system in good shape and following local rules.

Testing the System

After installing an oil water separator, it’s key to test it. This ensures it works right and meets rules. We’ll look at how to do initial tests, check for leaks, and make sure everything works well.

Conducting Initial Tests

Begin testing right after you set it up. Watch how water flows and how the system handles oily water. This helps find any problems early on.

Checking for Leaks

Looking for leaks is very important. Check all connections and the separator for any signs of leaks. Tools like dye tests can find hidden leaks fast. Fixing leaks quickly keeps the system running smoothly and follows environmental laws.

Ensuring Proper Functionality

Make sure every part of the system works right. This includes the oil content monitor and filters. Regular checks help keep the system working well and meet environmental standards.

Routine Maintenance Guidelines

Keeping an oil-water separator in good shape is key for its long-term success. By following routine maintenance, you ensure it works well, meets environmental rules, and saves money. Important tasks include cleaning the coalescing media, checking oil skimming, and doing regular inspections to catch problems early.

Cleaning and Maintaining Coalescing Media

Cleaning the coalescing media is a must to keep it working right. Taking out debris and oil helps it perform better and last longer. Using bioremediation can also cut down on sludge, showing the value of keeping the media clean.

Monitoring Oil Skimming Process

It’s important to watch the oil skimming closely to catch all the oil. High flow times can cause contaminants to spill over if not handled right. Using oil-only absorbent pads helps recycle oil and avoid rule breaks. Also, using high-pressure, low-volume sprays when washing vehicles can reduce oil in the separator.

Scheduling Regular Inspections

Regular inspections help spot problems before they get big. They check how well the separator’s parts are doing and if the system is working right. Sticking to maintenance rules helps avoid costly fixes and keeps the separator running smoothly.

Troubleshooting Common Issues

Fixing common problems with oil water separators is key to keeping them running well and meeting environmental rules. Knowing how to tackle these issues helps operators act fast when problems pop up. This guide will help you spot and fix separation problems, flow issues, and share maintenance tips to make your separator last longer.

Identifying Separation Problems

Keeping a close eye on your oil water separator is important. Look out for signs like too much oil or oil mixed with water. Catching these problems early can stop them from getting worse. Regular checks help spot any performance changes quickly.

Resolving Flow Issues

Flow problems can really slow down your oil water separator. Often, blockages or leaks are the cause. Make sure to check for clogs in pipes, valves, and tanks. Also, make sure pumps are installed right and inlets are clean. Keeping an eye on these things helps keep your separator running smoothly.

Maintenance Tips for Longevity

Good maintenance is essential for your oil water separator to work well for a long time. Regular cleaning and checking the coalescing media can really help. Scheduled checks are important for finding problems early and reducing downtime. Doing maintenance the right way keeps you in line with standards and saves time and money. For more on how to install and maintain your separator, check out Freytech.

Contact Freytech Inc. for Assistance

If you need help with oil water separators, Freytech Inc. is here for you. They offer top-notch customer support and aim to make you happy. They can help with installation, upkeep, and getting the most out of your separators.

Looking to follow local rules or improve how you handle wastewater? Their team is eager to help you.

Expert Consultation Services

Freytech Inc. is an expert in many fields, like mechanical workshops, gas stations, and industrial sites. They offer custom solutions to meet your needs. Their advice is based on your specific situation, ensuring you get the best service.

Customer Support Information

Ready to talk to Freytech? Call us at +1 (305) 372-1104. Our customer support team is ready to help with any questions about oil water separators. Contact Freytech Inc. today to start managing stormwater effectively.