Do you know How to Maintain a Below Ground OWS System? or that ignoring your below ground Oil Water Separator (OWS) can cause big problems? It can lead to expensive fixes and serious issues with environmental rules. Keeping your OWS system in good shape is key to avoiding these problems.

These systems are often hidden, so they need careful upkeep. This ensures they work well and follow strict rules. Without regular checks, they can harm the environment and break rules.

This guide will show you how to keep your OWS system running smoothly. It covers important steps like regular checks, cleaning, and using new tech to stay in line with rules. By following these tips, you can protect your investment and the planet.

Key Takeaways

- Regular inspections of below ground OWS systems are crucial to prevent costly repairs.

- Strict maintenance schedules are needed due to their underground placement.

- Cleansing media plates and managing inlet areas can improve efficiency.

- Qualified professionals should oversee maintenance to adhere to environmental compliance.

- Contacting experts for specific OWS needs ensures you are meeting all regulations.

- The OWS Management Program integrates best practices for handling oily wastewater.

Understanding Below Ground OWS Systems

Below ground OWS systems are key for separating oil and water. They help protect the environment and follow rules. These systems use advanced tech to make sure water released into rivers and lakes is clean.

Definition and Purpose

These systems remove oil from water, like from stormwater or industrial waste. They use gravity and special plates to separate oil from water. This makes sure the water released is safe for the environment.

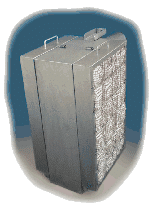

Components of an OWS

Important parts of an OWS include tanks, plates, pipes, and access points. Each part is crucial for effective oil separation. The design of these parts helps the system work well in keeping oil out of water.

Benefits of Below Ground Systems

OWS systems have many advantages. They efficiently separate oil, reducing harm to the environment and meeting EPA standards. They save space by being underground. Also, they help keep waterways clean by stopping pollutants.

Importance of Regular Maintenance

Keeping below ground OWS systems in good shape is key for smooth operation and following environmental rules. In New York City, rules say oil levels in water must be under 10 PPM. This rule is important to avoid fines and protect the environment.

Compliance with Environmental Regulations

It’s vital to keep OWS systems up to date for environmental rules. Tools like EcoLine B underground separator help remove oil before water goes into sewers. These systems must work well to meet local water standards. Not following these rules can lead to big fines and harm public health.

Advantages of Preventive Care

Preventive care in OWS helps spot problems early. Regular upkeep, like cleaning and removing waste oil, lowers the risk of contaminated water. This approach keeps systems running well and equipment lasting longer, saving on repair costs.

Long-term Cost-Effectiveness

Regular maintenance is a smart long-term investment for OWS system managers. It cuts down on emergency repair costs and keeps systems running at their best. Systems like Freytech Inc.’s EcoLine B series can handle a lot of water and keep oil levels low. By focusing on maintenance, facilities can save money and avoid unexpected expenses in managing wastewater.

Key Maintenance Procedures

Keeping below ground Oil Water Separator (OWS) systems in top shape is key. Regular checks help stop oil and solids from building up. This keeps the system working well and meets all standards.

Routine Inspections and Audits

Regular checks and audits are crucial for the OWS’s health. These inspections catch problems early, like wear and contamination. It’s especially important to check the inlet area after the first month.

Only trained people should do these checks. They should look for solids, sludge, and oil buildup at set times.

Cleaning and Degreasing

Cleaning the OWS is vital for its efficiency. Regular cleaning stops clogs and keeps the system running smoothly. When cleaning, remove parts carefully to ensure everything gets clean.

Monitoring Oil Separation Efficiency

Checking how well the OWS separates oil is essential. This ensures it meets MARPOL rules, keeping water clean. Regular checks help fix problems fast, keeping the environment safe.

Utilizing Freytech Enhanced Coalescing Technology

Freytech Enhanced Coalescing Technology is key in improving oil-water separation systems. It handles different types of hydrocarbons well, meeting many industrial needs. Freytech’s systems lead in separation efficiency and meet environmental standards.

Overview of the Technology

Freytech’s Enhanced Coalescing Technology is at the heart of its innovation. It can separate non-emulsified oils to 5 PPM efficiency. It also excels at emulsified oils, reaching 0.1 PPM efficiency. This makes Freytech’s oil water separators leaders in environmental sustainability.

Advantages of 5 PPM Separation Efficiency

Reaching 5 PPM separation efficiency brings big benefits to industries. It helps meet strict environmental rules. Freytech’s systems remove organic pollutants and lower discharge risks. For big facilities, like the EcoLine B model, this efficiency means a cleaner operation without losing productivity.

Achieving 0.1 PPM Separation Efficiency

Freytech’s systems can hit 0.1 PPM separation efficiency, setting a new standard in oil-water treatment. This high precision manages even tiny emulsified oil amounts. The EcoSorp model shows this capability, making it perfect for industries needing top-notch wastewater treatment.

Signs Your OWS Needs Attention

Property owners need to watch for signs that their OWS needs maintenance. Spotting these signs early can stop bigger problems and keep you in line with local rules. Look out for a drop in separation efficiency, bad smells from leaks, and alarm signals from the monitoring system.

Decreased Separation Efficiency

A big warning sign is when the OWS’s separation efficiency drops. This means the treated water has too much oil, leading to bad discharges and possible legal trouble. Keeping an eye on how well the OWS works helps avoid expensive fixes.

Unpleasant Odors or Leaks

Bad smells can mean there’s a leak in the oil water separator. These smells show the system isn’t working right and needs checking. Also, if you see leaks, it’s a sign of a problem that could cause big trouble if ignored.

Warning Indicators in Monitoring Systems

Monitoring system alerts are key to catching problems early. Alarms tell you when something’s wrong, so you can fix it fast. Keeping these systems in good shape helps protect the environment from oil spills.

How to Maintain a Below Ground OWS System? Best Practices for Maintenance

Following OWS maintenance best practices is key for below ground Oil/Water Separator systems to work well. Regular maintenance keeps these systems in top shape and follows the law. It also makes them last longer and work better.

Scheduling Regular Servicing

It’s important to schedule OWS system servicing regularly. This should be based on how often they’re used and early checks. You should do maintenance at least once a year, or sooner if there’s too much sludge.

Also, plan maintenance during busy times to avoid problems.

Keeping Records of Maintenance Activities

Keeping detailed records of maintenance is crucial. It helps track how well the system is doing and makes sure you follow the rules. This is important for spotting trends and fixing issues before they get worse.

Staff Training and Safety Protocols

Training staff on OWS systems is essential for safe and effective operation. It teaches them how to use equipment safely and do maintenance right. This lowers the chance of accidents during maintenance.

It’s also good to have regular training to keep staff up-to-date on the latest best practices for oil/water separation systems.

When to Seek Professional Help

Keeping your below ground oil/water separator (OWS) in top shape is crucial. Sometimes, you need OWS professional help for complex problems. Knowing when to ask for help can prevent bigger issues and keep your system running smoothly.

Identifying Complex Issues

Look out for signs like decreased separation efficiency or strange smells. These often mean you need expert help. While regular maintenance can solve many problems, some issues need special skills. Getting OWS professional help ensures these problems are solved right.

Emergency Response Measures

Big incidents like oil spills need quick action. Having a plan and service agreements with pros is key. Fast action reduces harm, keeps you in line with laws, and protects nature.

Freytech Inc. Maintenance Support

Freytech Inc. provides detailed maintenance support for your OWS. They handle everything from routine checks to emergency fixes. With Freytech, your system stays efficient, keeping the environment safe. Contact them for any system concerns.

Contact Freytech Inc. for Expert Assistance

Need help with your below ground OWS system? Call our team at Freytech Inc. at +1 (305) 372-1104. Our experts are here to help with your specific needs and guide you through oil-water separation.

How to Reach Us

At Freytech Inc., we’re all about top-notch support. Whether it’s maintenance or advice on OWS solutions, we’re here for you. We’re quick to respond and easy to reach, making it simple for you to get in touch.

Our Commitment to Excellence

We know every industrial need is different. That’s why we offer nine advanced oil-water separator models. From the EcoLine A for fueling stations to the EcoSorp for emulsified oils, our solutions are innovative and eco-friendly.

Exploring Our OWS Solutions

Our separators are top-notch, and our optional oil skimmer collects oil with 99.7% purity. This not only saves on waste management costs but also keeps you in line with environmental laws. Explore our solutions and see how we can help you meet your sustainability goals.