Have you ever thought about what happens when oil is not removed or cleaned from our waters? The dangers are huge, affecting both the environment and living creatures. Cleaning up oil spills is key to protecting marine life and keeping our water clean. It’s not just about looks; it’s about saving our planet.

Not removing oil from water can lead to serious problems. Light oils evaporate fast but are dangerous right away. Heavy oils stay longer, causing big ecological problems. Sea birds are very sensitive to oil, which can kill them and upset the food chain.

It’s important to know the risks of oil in water. This knowledge is vital for anyone working with water in industries.

Key Takeaways

- Oil spills pose severe risks to marine ecosystems and human health.

- Immediate action is critical to lessen the environmental damage from oil spills.

- Light and heavy oils need different cleanup methods because of their unique effects.

- Seabirds are very vulnerable to oil, showing the wide ecological harm.

- Good oil spill management can greatly reduce long-term damage.

Introduction to Oil Water Separation

Oil water separation is key in many industries. It makes sure water is clean and safe for our ecosystems. It’s also vital for keeping people healthy and following the law.

Importance of Removing Oil from Water

Removing oil from water is critical to avoid harming our environment. Oil spills from factories, cars, and maintenance can pollute our water. Without the right methods, companies face big fines and damage to their reputation.

In places with lots of water flow, old oil-water separators don’t work well. That’s why new, better technologies are needed to clean our water.

Common Sources of Oil Contamination

Knowing where oil pollution comes from helps businesses stop it. Places like oil rigs, factories, car shops, and water treatment plants all make oily waste. For example, car service centers create a lot of oily water that needs special treatment.

Overview of Oil Water Separator Technology

Today’s oil water separator tech, like Freytech’s, uses advanced filters to catch more pollutants. These filters help make wastewater cleaner and lower the chance of oil spills. Keeping these systems in good shape is important for better performance and following the law.

Consequences of Oil Contamination

Oil spills harm ecosystems and human health. It’s vital to tackle these issues for the environment and communities. Oil spills affect marine life and food sources far from the spill site.

Environmental Impact and Marine Life

Oil spills are devastating for marine life. They pollute habitats, causing harm to fish and mammals. Cleanup efforts help, but restoring ecosystems is hard.

The effects of oil spills spread through the food chain. This impacts local economies that rely on fishing and tourism.

Health Risks to Humans

Oil exposure poses health risks to people. Contact with contaminated water can cause respiratory issues and skin problems. Long-term exposure can lead to serious health issues.

Communities near oil spills face health problems. They also suffer economically due to environmental damage.

Damage to Water Treatment Facilities

Oil spills damage water treatment facilities. This requires expensive repairs and disrupts service. Quick action is needed to prevent further contamination.

Delays in response make recovery harder. This affects essential health services for communities relying on these facilities.

Regulatory Standards for Oil Discharge

North American hydrocarbon discharge limits are key to protecting our environment. They ensure we follow environmental laws. Untreated wastewater from air compressors with over 40 ppm of oil is not allowed. This is because condensate from these compressors usually has around 300 ppm of oil.

North American Hydrocarbon Discharge Limits

The limits for hydrocarbon discharge in North America are set by strict rules. These rules help keep our water clean by reducing harmful discharges. The Vessel Incidental Discharge Act (VIDA) affects about 85,000 vessels, making sure they follow strict guidelines.

Importance of Compliance for Businesses

Businesses must follow these strict standards to avoid legal trouble. Not meeting these limits can harm a company’s reputation and legal standing. Companies could face fines of up to $25,000 a day for first-time offenses, and up to $100,000 a day for repeat offenses.

Penalties for Non-Compliance

Non-compliance can be very costly for businesses. The fines can add up quickly, affecting a company’s long-term success. To avoid these problems, companies should use advanced oil-water separators. This helps them follow environmental laws and stay compliant.

Benefits of Using Freytech Oil Water Separators

Freytech’s oil water separators offer many benefits. They improve both efficiency and protect the environment. These separators work well, making discharges cleaner than required by law.

Superior Separation Efficiency

Freytech’s separators use advanced technology. They remove hydrocarbons from water sources effectively. They can handle up to 2000 PPM and achieve separation rates as low as 0.1 PPM.

This high performance helps meet environmental standards. It also supports sustainability efforts.

Enhanced Coalescing Technology Explained

The key to these separators is enhanced coalescing technology. It captures small oil droplets, improving separation rates. Freytech’s technology handles hydrocarbons with a specific gravity between 0.82 and 0.88.

This shows it can handle different types of oil found in industries.

Reusability and Longevity of Coalescing Media

Freytech separators have a special feature: the coalescing media can be reused. This makes maintenance easier and extends the system’s life. Regular cleaning keeps the media working well.

This makes the system cost-effective and reduces environmental impact. The reusability of coalescing media fits well with the need for environmental responsibility.

Freytech’s Separation Capabilities

Freytech leads in oil water separation with advanced tech. Their systems can separate oil from water with a 0.1 PPM efficiency. This means they remove hydrocarbons very effectively, leaving little to no contamination behind.

Achieving 0.1 PPM Separation Efficiency

Freytech’s separators are top-notch, reaching a 0.1 PPM separation efficiency. This high standard meets strict environmental rules and ensures clean water. They remove hydrocarbons from water, playing a key role in many industries.

Effective Removal of Various Hydrocarbons

Freytech’s oil water separators can handle different types of hydrocarbons. They remove both free and emulsified oil, making them versatile. The clean water they produce often goes beyond what’s expected.

Optional Features for Improved Performance

Freytech’s oil water separators come with extra features to boost performance. For example, their patented oil skimmers make oil removal very efficient. These features make their systems more flexible and effective. Learn more about their advanced solutions on their website.

The Value of Recycled Oil

Recycling used oil brings big economic wins. It cuts down on disposal costs and turns waste into valuable goods. This approach makes businesses more profitable and sustainable.

Economic Advantages of Efficient Oil Recovery

Oil recycling offers more than just saving money. Companies that recycle can avoid disposal costs. They might even get paid for their used oil. As demand for green energy grows, so does the value of recycled oil.

Processes for Recycling Separated Oil

Advanced purification methods are used to recycle oil. This ensures the oil meets high standards for reuse. It also creates products like glycerin for the pharmaceutical and cosmetic industries. These steps help companies follow rules and support the environment.

Environmental Benefits of Reusing Oil

Using recycled oil has huge environmental benefits. It helps reduce harmful waste and emissions. Biodiesel made from cooking oil is a cleaner alternative to fossil fuels. This supports cleaner energy and diversifies the U.S. energy mix.

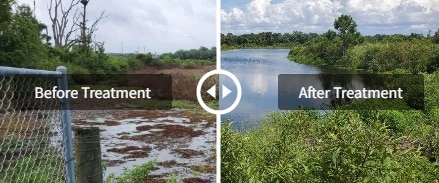

Case Studies and Success Stories

Many case studies show how Freytech’s oil water separators work well in different industries. These stories tell of new ways to deal with oil spills. They also show how Freytech helps meet environmental rules.

Effective Solutions Implemented by Freytech

Freytech has come up with smart ways to separate oil from water. Their technology helps get more oil back, which is good for the environment. This has changed how industries handle oil spills, making them safer and cleaner.

Feedback from Satisfied Clients

People who use Freytech’s products are happy. They say it helps them follow rules better and work more efficiently. They also appreciate how Freytech’s separators help the planet, showing the value of good oil separation.

Measurable Outcomes and Improvements

Studies show big wins, like less oil pollution. Workplaces are running better, thanks to Freytech’s solutions. These gains show the big difference Freytech makes for the planet and for business.

Maintenance of Oil Water Separators

Keeping oil water separators in top shape is key. Regular cleaning of coalescing media is a must. This should happen every six months, but it can vary based on how much you use it and local laws.

This not only makes the media last longer but also boosts efficiency.

Regular Cleaning and Care for Coalescing Media

It’s vital to keep the coalescing media clean. If oil builds up, it can cut the separator’s efficiency by 25%. Regular checks are needed to keep oil and water levels right and prevent pollution.

Good upkeep can make the unit last 50% longer. It’s also important to keep records of maintenance for at least six years to follow the rules.

Troubleshooting Common Issues

Spotting common problems with oil water separators quickly is important. About 10% of these systems fail because of bad maintenance, leading to oil spills. Daily, weekly, and monthly checks can catch leaks early.

Almost 40% of leaks are missed in systems that aren’t well looked after. Getting help from experts for regular checks can make the system work better and save on repair costs, which can be up to 20% of the total cost.

Tips for Ensuring Optimal Performance

Following the best practices is key to getting the most out of oil separators. Training staff can cut down on mistakes by up to 30%. This ensures they know how to keep things running smoothly.

Using oil-only absorbents can stop oil from getting into the sewer system. This is important to avoid big problems. Regular clean-ups, after spills or when certain levels are reached, help follow environmental laws and avoid fines that can be as high as $37,500 a day.

Following these tips can make operations smoother and save money in the long run.

Conclusion: The Importance of Oil Removal

It’s vital to tackle oil contamination risks, as they harm more than just the environment. Every year, over 14,000 oil spills happen in the U.S. These spills damage aquatic life and cost a lot of money. With 70% of marine spills coming from operational mistakes, it’s clear we need better oil removal plans.

Summary of Risks from Oil Contamination

Not handling oil spills well can have big problems. Oil can spread up to 10 miles if not stopped quickly. This harms marine life and water quality. Removing oil well helps protect the environment and saves money, which can be from $200,000 to $15 million.

Call to Action for Businesses

Companies using water should focus on new oil removal methods. These methods help meet rules and protect water sources. For top oil water separation solutions, call Freytech Inc. at +1 (305) 372-1104. We can help keep your operations and the environment safe.