Have you thought about how cooking oil quality affects food and customer satisfaction in restaurants? In a field where taste and consistency matter a lot, managing oil waste is a big challenge. Oil is key in many food operations, so using good oil removal methods is important for business success and the environment.

This article looks at seven new oil recovery services for the food industry. These services help meet strict standards, protect the environment, and make operations more efficient.

Key Takeaways

- Proper oil removal is essential for maintaining food quality and customer satisfaction.

- Eco-friendly solutions contribute to the sustainability of food industry operations.

- Regular management of used cooking oil can prevent costly contamination.

- Adhering to oil discharge regulations protects both the environment and your business.

- Advanced oil recovery services can lead to long-term cost savings.

Understanding Oil Removal and Its Importance

Oil removal is very important in many industries. It helps keep things clean and follows rules. The method of oil water separation is key to removing oil and grease from water. This is essential for keeping food clean and safe.

What is Oil Water Separation?

Oil water separation is a way to separate oil from water. It’s important for cleaning up oil spills. New technologies have made it better at handling big spills, like the one in Huntington Beach, California.

The Role of Oil Separator Packages

Oil separator packages are vital for oil water separation. They help remove hydrocarbons, making water cleaner. This is good for the environment and helps follow rules.

Compliance with North American Regulations

Understanding North American regulations is key for food industry operations. These rules set specific limits on hydrocarbon discharges. Following these rules helps keep the environment safe and supports sustainable practices.

Hydrocarbon Discharge Limits Explained

North American regulations have strict limits on hydrocarbon discharges. They cap emissions at a maximum of 10 Parts per Million (10 PPM). This rule is important for keeping the environment safe, which is critical in the food industry.

Going over these limits can lead to big fines. This shows how important it is to have good oil removal solutions. These solutions help meet the rules and avoid penalties.

Importance of 10 PPM Standards

Following the 10 PPM standards is a big step towards being responsible and sustainable. Keeping hydrocarbon levels below these limits helps avoid fines. It also shows a company’s commitment to the environment.

For the food industry, meeting these standards is essential. It keeps operations in line with North American rules. It also helps maintain a good reputation in a world with more regulations.

Freytech Inc.’s Innovative Technology

Freytech Inc. is leading in oil water separation technology. They offer solutions that beat traditional methods in the food industry. Their enhanced coalescing technology removes oil efficiently, meeting both regulatory standards and operational goals.

Enhanced Coalescing Technology Overview

This technology makes separators remove oil amazingly well. They handle flow rates from 25 to over 640 gallons per minute. Freytech’s separators can separate oils as low as 5 PPM, and even 0.1 PPM for emulsified oils. This precision meets and goes beyond North American regulations.

Achieving 0.1 PPM Separation Efficiency

Freytech Inc. is dedicated to excellence. Their skimmed oil is 99.7% pure, with almost no water. This reduces waste disposal problems. Unlike many competitors, Freytech’s solutions save money and help the environment. They set the standard for oil management in the food industry.

Types of Hydrocarbons Freytech Separates

In the food industry, many hydrocarbons can get into wastewater. It’s key to know these hydrocarbons for good treatment and following rules. Freytech’s tech helps separate hydrocarbons from water well, making our environment safer and cleaner.

Common Hydrocarbons in the Food Industry

Food industry hydrocarbons include motor oil, diesel fuel, and gasoline. These come from machine upkeep, fuel leaks, and washing equipment. It’s vital to separate these hydrocarbons well to manage wastewater and meet strict rules, like in North Carolina. Freytech’s systems remove these substances efficiently, keeping levels under the allowed limits.

Effective Separation of Motor Oil and Diesel

Freytech’s oil water separators are top-notch at separating motor oil and diesel. They remove hydrocarbons down to 0.1 parts per million (PPM). This meets federal discharge limits of 10 PPM and helps businesses stay efficient. They offer tanks from 1,000 to 20,000 gallons, fitting various industrial needs for managing hydrocarbons.

Benefits of Freytech Oil Water Separators

Choosing Freytech’s oil water separators offers many benefits for businesses. One key advantage is the reusability of the coalescing media. This media can be cleaned with a spray wash, extending its life and cutting down on replacement costs. This makes the system very cost-efficient.

By not needing to change the media often, companies save money. They can keep their systems running well without breaking the bank.

Reusability of Coalescing Media

The coalescing media in Freytech separators can be cleaned and reused. This makes the waste disposal process more sustainable. It also helps reduce waste and promotes better use of resources.

This easy maintenance is a big plus for managing filters in tough places like the food industry.

Long-Term Cost Efficiency

Another great reason to go with Freytech’s technology is its long-term cost savings. The initial cost of these separators pays off as maintenance and operational costs go down over time. They can even meet strict water quality standards, keeping costs low.

Companies can avoid expensive fines for not managing waste properly. They also save a lot on waste disposal costs. To learn more, visit Freytech’s oil water separators page.

Integration of Optional Features

Freytech Inc. offers a variety of optional features to boost their oil separation systems. The patented oil skimmer is a key feature. It makes oil separation more efficient by automating oil draining, leading to cleaner products.

Patented Oil Skimmer Advantages

The patented oil skimmer brings many benefits for oil recovery. It allows for almost complete oil separation from water, keeping purity levels up to 99.7%. This ensures the oil is of high quality, perfect for the food industry.

Using water cut monitors also helps avoid penalties for too much water. It keeps operations in line with what customers expect.

Mechanically Draining Separated Oil

The automated oil draining system is another important feature. It makes handling separated oil easier, reducing the need for manual work. Digital flow computers make tracking performance easier, without needing a lot of manual effort.

These features improve accuracy in billing and help increase revenue. They show Freytech’s dedication to excellent oil recovery services. For more details on these features, visit this link.

The Value of Efficiently Skimmed Oil

Efficient oil skimming technology turns used oil into valuable resources. It works well in different water conditions, from calm to rough. This makes it easier to recycle oil into renewable diesel, a cleaner fuel than traditional petroleum.

By treating oil properly, businesses can enjoy economic gains. This process helps the environment and boosts profits.

Recycling Used Oil

Oil skimmers remove both petroleum and food oils, helping the recycling process. They can pull out a lot of oil, but it might take more than one pass. This is because different oils need different methods to be removed fully.

This technology helps businesses follow environmental rules. It also makes oil recycling a profitable venture. This way, companies can be green and make money at the same time.

Economic Benefits for Food Industry Businesses

Getting oil skimmers can cost a lot at first. But, over time, it saves money on wastewater treatment and avoids fines. It also makes equipment last longer by keeping oil out of water.

Using oil skimmers helps businesses meet regulations. It also opens up new ways to make money from recycled oil. This is a win-win for the environment and the bottom line.

Case Studies: Successful Implementations

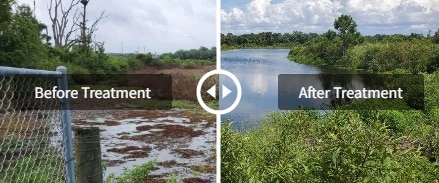

Freytech has shown its dedication to changing the food industry with its oil removal solutions. These technologies have made a big difference in real-world settings. Clients have seen big improvements in how they work and meeting discharge standards.

Real-World Applications of Freytech Solutions

Jim McKenzie, a restaurant owner, grew his business from three to eighteen locations with Freytech’s help. He used the Total Oil Management system. This led to fewer safety issues, like back injuries and slips.

McKenzie Foods saw a big drop in workers’ compensation claims. This shows how kitchen operations got more efficient.

Customer Testimonials and Results

Customers say Grease Lock® disposable filters cut down on hood cleaning. They also made operations smoother. The Total Oil Management system saved labor hours, letting staff do more important tasks.

McKenzie said this technology improved safety and efficiency in the kitchen. It was a smart choice for him.

VLI also saw great results. Their lubrication training improved their ASCEND™ score from 24% to 90% in four years. This shows Freytech’s solutions can really help businesses grow. They offer better service and more consistent products, as many customers have shared.

How to Get Started with Freytech Inc.

Food industry professionals looking for oil removal solutions can easily start with Freytech Inc. First, understand your oil separation needs and any rules you must follow. Freytech’s team is ready to offer expert advice to help you. They use their deep market knowledge to help you choose the right oil/water separator.

Contact Information and Support

Freytech provides great support to explore your options. You can contact them through their support channels to talk about your needs. They can show you how their technology can make your operations more efficient.

Phone Consultation with Experts (+1 305 372-1104)

Call Freytech at +1 305 372-1104 to talk to their team. They can help with questions about their technology or your wastewater treatment plan. Freytech is dedicated to helping your business meet standards and save money in the long run.