Have you ever thought about how oil separation can boost a business’s efficiency and care for the environment? In the world of petroleum refining and wastewater treatment, oil separation is key. It brings five main benefits to businesses: better efficiency, following environmental rules, saving money, working better, and being green.

By using the latest tech from Freytech Inc., companies can get the most out of these advantages. They can handle today’s challenges in managing resources and looking after the planet.

Key Takeaways

- Oil separation makes operations more efficient in many industries.

- Good oil separation helps follow environmental laws better.

- Using oil separation tech can cut down costs a lot.

- Advanced systems help the planet by recovering oil and reducing waste.

- Freytech Inc.’s new solutions fit the needs of different businesses.

What is Oil Separation?

Oil separation is key to removing oil, grease, and hydrocarbons from water. Techniques like gravity separation, coalescence, and Dissolved Air Flotation (DAF) help a lot. These methods are vital in many industries.

Definition of Oil Separation

The oil separation process is essential for managing oil and gas well production mixtures. These mixtures include petroleum, water, gas, and solids. By changing the temperature, we can make oil separation easier.

Gravity separation is the main method used. It works because oil and water have different densities. The longer oil stays in a separator, the better it separates. This is because calm conditions help a lot.

Importance in Various Industries

Oil separation is important in many fields, like manufacturing, automotive, transport, and food processing. These sectors need good oil-water separation to work well and protect the environment. It also saves money by avoiding damage to equipment.

There are many ways to separate oil and water, like flotation, centrifugation, and membrane filtration. Following environmental rules is also key. It helps keep natural resources safe and avoids big fines.

Compliance with Environmental Regulations

Following environmental rules is key for businesses, mainly those handling hydrocarbon discharge. In North America, the Environmental Protection Agency (EPA) sets limits on hydrocarbon discharge. For example, oil in air compressor wastewater can’t be more than 40 parts per million (ppm). This is much lower than the usual 300 ppm found in air compressor condensate.

These rules are in place to safeguard water and public health.

North American Hydrocarbon Discharge Limits

Strict oil-water separation rules show how vital it is to stick to hydrocarbon discharge limits. Breaking these can cost a lot, up to $25,000 a day for careless mistakes. If it happens again, the daily fine can jump to $50,000. The highest fines for intentional violations can reach $100,000 a day.

Agencies might also shut down operations until the rules are followed. This can really hurt a company’s productivity.

Benefits of Meeting 10 PPM Standards

Meeting the 10 PPM standard can save a company from big fines. It also makes a company look good for caring about the environment. Companies like Freytech can even go below 5 PPM, sometimes down to 0.1 PPM.

Following these strict rules can make operations safer, lower risks, and give a company an edge in the market.

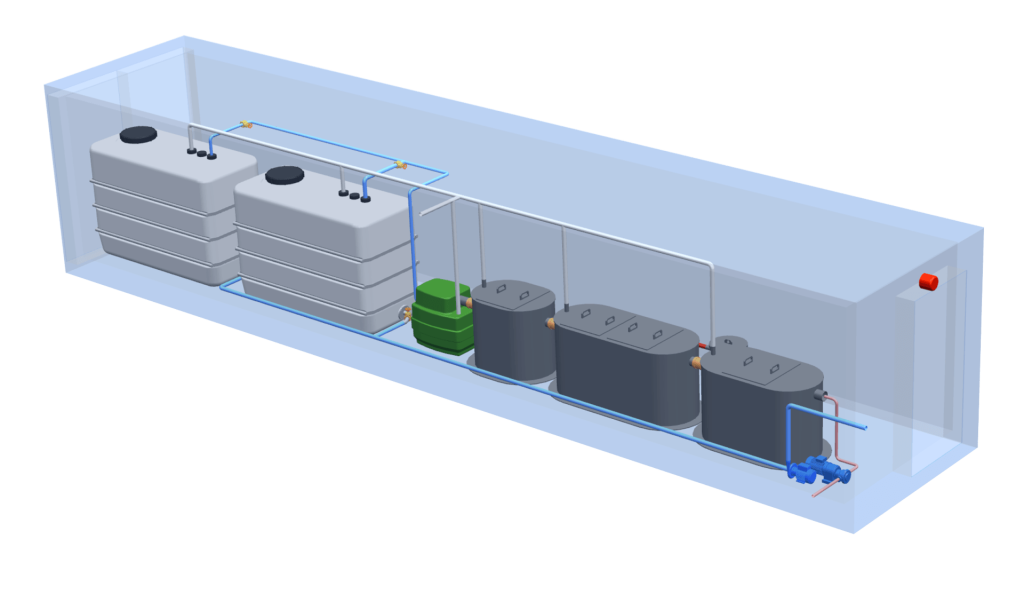

Freytech Inc.’s Advanced Solutions

Freytech Inc. is a leader in advanced oil separation solutions. They use cutting-edge coalescing technology to improve oil-water separation. Their systems are designed to meet environmental standards, effectively separating oils and recovering valuable hydrocarbons.

Enhanced Coalescing Technology

Freytech’s separators use oleophilic media for better separation. This technology boosts separation efficiency, with many models achieving results under 5 PPM. For very small amounts of emulsified oil, their solutions can reach 0.1 PPM, showing Freytech’s commitment to strict regulations and environmental care.

Separation Efficiency Goals

Freytech aims to exceed industry standards for oil separation. Their systems ensure effluent discharge is clean, avoiding fines and promoting sustainability. With flow rates from 25 to over 640 gallons per minute, they meet diverse industrial needs.

By investing in Freytech’s solutions, businesses can run more efficiently. They also have the chance to increase revenue by recovering valuable oil by-products.

Achieving Exceptional Separation Standards

Freytech Inc. focuses on top-notch separation standards to boost efficiency in many fields. They use cutting-edge tech and precise engineering for emulsified oil separation. Knowing fluid dynamics well is key for designing and using vertical separators in oil and gas.

Efforts to Reach 5 PPM Efficiency

Freytech uses advanced parts like baffles and mist extractors to hit 5 PPM efficiency. These parts help separate liquids by using gravity and density. The success of vertical separators depends on optimizing retention time for better separation.

By adjusting pressure and temperature, Freytech fine-tunes their systems for the best results.

Performance in Emulsified Oil Separation

Emulsified oil separation is tough in oil and gas, mainly with mixed hydrocarbon flows. Freytech’s solutions use coalescing plates and demisters to boost separation. This leads to better performance than old methods, isolating oil, fuel, and water well.

By cutting down on carryover and keeping products pure, Freytech’s systems help the environment. They meet strict environmental rules while keeping operations sustainable.

The Variety of Hydrocarbons We Address

Knowing about different hydrocarbons is key for oil-water separation industries. Freytech deals with many, like motor oil, diesel, gasoline, and jet fuel. Each one has its own challenges and solutions in oil-water separation.

Motor Oil and Other Fuels

Separating motor oil is critical for clean water and efficient fuel use. As we seek cleaner fuels, industries must find new ways to handle hydrocarbons. Good motor oil separation cuts down on environmental harm and boosts business efficiency.

Impact on Industries Using Refined Hydrocarbons

Refined hydrocarbons affect many areas, from making things to moving them around. Knowing how hydrocarbons act helps industries separate and manage them better. This reduces their harm to the environment. Advanced separation tech is vital for a greener, more sustainable future.

Cost Efficiency with Freytech Products

Businesses aiming to boost their efficiency should look into cost-saving oil separation methods. Freytech products are made to improve both performance and save money. They use reusable media, helping companies cut down on waste and boost profits.

Reusable Coalescing Media

Using reusable coalescing media greatly helps in saving costs. Unlike old methods that need lots of disposable parts, Freytech’s systems use these media for longer. This means less waste and lower costs for replacements.

These systems also separate oils well, showing big economic and environmental gains. Investing in Freytech’s systems is smart for both your wallet and the planet.

Maintenance and Longevity Benefits

Freytech products also offer big maintenance benefits. They are built to last, needing less upkeep. This means big savings for businesses in time and labor.

With Freytech, you save money, use reusable media, and need less maintenance. This makes Freytech products a great choice in today’s market. To see how Freytech can help your business, check out our resource page.

Automatic Oil Skimming Technology

Automatic oil skimming is a big step forward in managing industrial fluids, mainly in manufacturing. It boosts work efficiency and keeps coolant fluids in top shape for machining. By using this tech, companies can cut down on oil buildup, saving money and improving coolant quality.

Patented Oil Skimmer Features

Freytech’s unique skimmer tech is designed to remove tramp oil with little environmental harm. There are different skimmers like belt, disc, and tube ones, each fitting specific needs. For example, belt skimmers are great at pulling out oil, while tube skimmers work well in shallow areas.

This variety lets businesses pick the best skimmer for their needs. It makes automatic oil skimming more effective.

Efficiency of Skimmed Oil Purity

The oil skimmed by this tech is over 99.7% pure, making it key for recycling. It also means coolant lasts longer, saving up to 30% on replacement costs. Plus, using skimmers right can cut down on maintenance, reducing CNC machine downtime by up to 50%.

This not only makes work more efficient but also meets environmental rules. It helps avoid fines for not disposing of waste properly.

Environmental Sustainability Considerations

Environmental sustainability in oil separation is key in today’s industry. Companies now see recycling used oil as a valuable resource. It helps save resources and cuts down on environmental harm. By using smart strategies, businesses can gain big benefits while following environmental rules.

Recycling Used Oil as a Valuable Commodity

Recycling used oil turns waste into something useful. This involves collecting and cleaning the oil for reuse. It’s a big step towards environmental sustainability in oil separation.

Companies using the latest separation tech reduce waste and make the most of reused materials. They also focus on proper waste management and monitoring. This helps improve oil recycling efforts and moves them towards more green operations.

Reducing Water Pollution

The oil and gas industry has to deal with water pollution issues. It’s vital to find ways to cut down on water pollution. Advanced separation methods help clean extracted materials, keeping water sources safe.

Companies that follow best practices can greatly reduce water pollution risks. This makes their operations more eco-friendly and boosts their reputation.

Enhancing Operational Efficiency

Effective oil separation technologies are key to improving efficiency in many sectors. They help streamline workflows, leading to better productivity and less delay. This is important for businesses looking to run smoothly.

How Oil Separation Improves Workflow

Advanced oil separation mechanisms make workflows better. Oil skimmers can cut oil contamination by up to 95%. This makes water clean for reuse or safe disposal.

This is vital in industries where oil management is critical. In manufacturing and the automotive sector, oil separation from wastewater boosts efficiency by up to 50%. This leads to smoother operations and more output.

Reducing Downtime and Labor Costs

Optimized oil separation cuts downtime by about 20%. This is because many oil skimmers are easy to maintain. It also lowers operational costs and improves resource use.

Automation in oil separation also cuts labor costs. Companies see a 15% drop in operational expenses. This is because automation reduces the need for manual work, freeing staff for more important tasks.

Case Studies and Success Stories

Many companies have seen the benefits of Freytech’s advanced oil separation solutions. They’ve noticed improvements in how they work and their environmental impact. These stories show how Freytech’s technologies change oil-water separation in different industries.

Companies Benefiting from Freytech Solutions

A big oil company in the Ekofisk oilfield is a great example. It has produced over three billion barrels of oil. They needed to make their oil separation better to work more efficiently.

By using Freytech solutions, they greatly improved how well they separated oil. This saved them money and helped them meet environmental rules. These stories show how technology can give companies an edge.

Measurable Improvements

Black Mamba Rod Lift is another example. They used Freytech solutions to improve their inventory and work flow. Before, they spent a lot of time on monthly checks.

With Freytech’s technology, they worked much faster and more accurately. They also linked up with QuickBooks Online, making accounting easier. These changes show how Freytech solutions can boost productivity and save money.

Choosing the Right Oil Water Separator

Choosing the right oil-water separator is important. It affects how well it works and if it meets environmental rules. The right choice can improve performance and avoid expensive fines.

Factors to Consider

Several key factors should be considered when picking a system. The type of application determines the technology needed. This could be gravity-based, coalescing, or centrifugal separators.

The amount of wastewater is also important. Systems like API separators handle large volumes well. The type of oil in the wastewater affects the choice of separator. Some models are better at handling complex mixtures.

Customizing Solutions for Business Needs

Customized oil separation solutions are beneficial for businesses. They should look at their specific needs, like space and quality standards. Coalescing plate separators or hydrocyclones can solve space or flow rate issues.

Working with manufacturers can lead to solutions that meet their needs. These solutions improve efficiency and ensure they follow rules. They also help keep costs down.

Contact Freytech Inc. for More Information

Ensuring effective oil separation is key for businesses to meet environmental standards and improve operations. For more information on our advanced technologies and solutions, call us at +1 (305) 372-1104. Our team at Freytech Inc. Customer service is ready to answer your questions and guide you in finding the right solutions for your needs.

How to Reach Us

You can also reach us by email or through our website to learn more about oil-water separation options. We aim to provide detailed responses that meet your industry needs. This way, you’ll see how our innovative products can enhance your operations.

Setting Up a Consultation

We suggest setting up a consultation to tackle your specific challenges. In this meeting, we’ll evaluate your needs and explore how our advanced separators can improve your performance and meet environmental rules. Together, we can achieve more sustainable and effective oil separation solutions.