Ever wondered how industries keep their wastewater clean and cut costs? The answer often lies in oil water separator benefits. These systems remove harmful substances like oil and grease from water. They are key to keeping our environment safe.

In this article, we’ll look at the nine main benefits of oil water separator technology. These benefits help industries follow rules and work better. By reading on, you’ll learn how these solutions save money, help the environment, and more!

Key Takeaways

- Oil-water separators are essential for industries to meet environmental regulations and enhance operational efficiency.

- Gravity-based and coalescing plate separators are among the most common types, each with unique advantages.

- Effective oil-water separation aids in sustainable water management and resource recycling.

- Regular maintenance is key for the best performance and life of oil-water separator systems.

- Following rules can avoid expensive fines and legal trouble for industries.

Understanding Oil Water Separators

Oil water separators are key in managing wastewater with oil and grease. They are important in many industries. These devices protect water sources and help businesses follow environmental rules.

What is an Oil Water Separator?

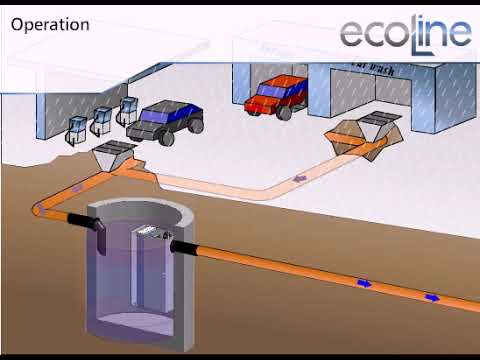

An oil water separator is a special device for treating wastewater. It removes hydrocarbons by using gravity. Oil floats to the top, making it easy to separate from water.

There are many designs for different needs in industries. Knowing about oil water separators helps facilities manage wastewater better. It also protects the environment.

How Do Oil Water Separators Work?

Oil water separators work through several steps. When wastewater goes in, gravity makes oil float on top. This makes it easy to separate from water.

Advanced designs, like steep-sloped clarifiers, improve separation. They remove solids well and reduce clogging. Facilities with good oil water separators save on maintenance and downtime. This boosts their overall efficiency.

Compliance with Environmental Regulations

Oil water separators are key for industries wanting to follow environmental rules. They help meet hydrocarbon discharge limits, which are strict in North America. Here, the limit is 10 Parts Per Million (PPM).

Thanks to advanced tech from Freytech Inc., some places can even go down to 5 PPM. This not only protects the environment but also makes operations more efficient.

Meeting North American Hydrocarbon Discharge Limits

It’s vital for industries with lots of oil and wastewater to follow hydrocarbon discharge limits. Not following these rules can cost a lot, sometimes thousands of dollars.

Keeping oil water separators in good shape is key to meeting these standards. Good waste management does more than save money. It also keeps waterways clean and helps public health.

Importance of Discharge Efficiency

High discharge efficiency in oil water separators can cut costs by up to 30%. Investing in the right tech can also make separators last longer. This means less need for repairs and replacements.

Going for compliant technology can save money and make operations more sustainable. Companies that focus on environmental benefits can also improve their reputation. They meet rules and do good for the planet.

Enhanced Separation Technology

Oil water separators have improved a lot in recent years. They work better because of new coalescing mechanisms. These systems can now separate oil from water more effectively, leading to cleaner water.

Advanced Coalescing Mechanisms

Today’s oil water separators use advanced coalescing technologies. These technologies help merge small oil droplets into bigger ones. This makes it easier to remove oil from water.

Thanks to these improvements, oil can be removed at rates of up to 98%. This shows how well these systems work. They also help meet strict environmental rules.

Achieving 0.1 PPM Separation Efficiency

Some oil water separators can separate oil at a rate of 0.1 PPM. This is very important in industrial settings. It helps keep the water clean enough to meet strict standards.

By using these advanced technologies, facilities can avoid water pollution. This helps protect our environment and promotes responsible waste management.

Versatility in Hydrocarbon Separation

Oil water separators are very versatile. They can handle many types of hydrocarbons. This includes motor oil, diesel, gasoline, and even jet fuel. They are key in many industries.

There are different types of oil water separators. Each one is designed for specific needs in various sectors.

Types of Fuels and Oils Separated

Oil water separators can treat different fuels. They are used in car shops for oil changes and in oil storage areas. These separators work well with hydrocarbons that have a specific gravity between 0.82 and 0.88.

Advanced models can even separate hydrocarbons to levels below 5 PPM. This is from influent concentrations as high as 2000 PPM. This ensures they meet environmental standards.

Applications Across Various Industries

Oil water separators are used in many places. This includes mechanical workshops, car washes, and wastewater treatment facilities. Installing these systems is important to follow local regulations.

These regulations protect groundwater and prevent contamination. These systems can treat wastewater at up to 1000 Imperial gallons per minute. This shows how effective they are in demanding situations.

Using these technologies helps businesses work more efficiently. It also reduces the environmental harm caused by hydrocarbons.

Cost-Effective Waste Management

Using an industrial oil water separator can change how businesses handle waste. These systems help by recycling oils, turning a problem into a valuable asset. This way, companies can cut down on hazardous waste, saving money on disposal and avoiding fines.

Reducing Costs with Efficient Recycling

Industrial oil water separators do more than just meet regulations. They let businesses recycle oils, creating a new income source and cutting waste costs. For example, oil from compressors can be captured and reused. This not only saves money but also makes operations more efficient.

Financial Benefits of Oil Recovery

Businesses can save a lot by using this technology. Oil recovery not only saves money right away but also helps achieve long-term sustainability goals. Using waste oil for heating can cut costs by up to 80%. As companies aim to be more efficient and green, investing in oil water separators is key.

Reusable Coalescing Media

Oil water separators work better with reusable coalescing media. This part is made to last and needs little upkeep, like a quick spray wash. Keeping it clean helps it last longer, saving money in the long run.

Places that use this media spend less on replacements. This keeps their costs down.

Longevity and Maintenance of Coalescing Media

The life of coalescing media is key to oil water separators’ success. With the right care, it can go through many uses without losing its power. This means less money spent on new parts.

It also helps meet environmental rules and cuts down on waste. This is good for the planet and the wallet.

Cost Savings from Reusable Components

Choosing reusable parts saves money for businesses. They use less water and spend less on new parts. This can cut water use by half.

Companies save a lot of money. This makes oil water separators a smart choice. For more on how they work, check out this resource.

Automatic Oil Skimming Features

Modern oil water separators now come with automatic oil skimming features. This shows big steps forward in technology. The mix of oil water separator systems and special oil skimmer tech makes removing oil very efficient. This boosts the performance of fluid systems in industrial places a lot.

Benefits of Patented Oil Skimmer Technology

Patented oil skimmer tech makes taking out tramp oil easy. This means less manual work and better oil quality, often up to 99.7% pure. Using good oil skimming systems can save a lot of money by making coolants last longer.

It also helps meet environmental rules, avoiding fines and improving a company’s image.

How Skimming Improves Efficiency

Knowing how skimming boosts efficiency is key for better operations. Oil skimmers remove oil smoothly by using the difference in density between oil and water. For example, belt and disc skimmers target different oils well, keeping coolants good to use.

Cleaner coolants mean less wear on tools, cutting down costs and boosting productivity. Adding oil skimming to maintenance routines can cut downtime. This makes CNC machining work flow better.

To learn more about these advanced systems, check out the benefits of oil water separator.

Improved Operational Efficiency

Oil water separators greatly improve efficiency in many industries. They cut down on downtime for handling wastewater. Their advanced designs help facilities meet strict rules without needing manual help often.

This makes water treatment smoother and keeps productivity high.

Reducing Downtime with Reliable Systems

Companies using oil water separators see less downtime. For example, in oil and gas, they stop corrosion caused by moisture. This saves a lot on maintenance and repairs.

In aviation, they ensure dry air for pneumatic systems. This lowers icing risks that can slow down planes. These examples show how oil water separators boost efficiency.

Streamlining Water Treatment Processes

Good water treatment is key to following environmental laws. Facilities with oil water separators cut costs for disposing of contaminated water by up to 50%. This helps their budgets and keeps them in line with rules.

Special designs, like coalescing and centrifugal types, remove more moisture. This keeps operations running smoothly and protects products.

Contribution to Sustainability

Oil water separators are key to making industries more sustainable. They help manage oily wastewater effectively. This not only meets legal standards but also helps businesses reduce their environmental footprint.

By using the latest in separation technology, companies can treat waste oil properly. This cuts down pollution in soil and water. It’s a big step towards a cleaner environment.

Minimizing Environmental Impact

Oil water separators help lower environmental pollution. They remove harmful substances from waste oil through processes like sedimentation and filtration. This makes the air cleaner and reduces greenhouse gas emissions.

This shows how important these systems are for responsible waste management. They help keep our planet healthier.

Promoting Responsible Waste Disposal

Recycling waste oil helps businesses and the environment. It cuts down on the need for new oil. Advanced technologies turn waste oil into high-quality base oils, saving resources.

Government support and new technologies have made this sector grow. It meets the demand for sustainable practices in industries. Using oil water separators boosts a company’s image and follows the law, leading to a greener future.

Choosing Freytech Inc. for Your Needs

Choosing Freytech Inc. means getting access to cutting-edge technology for managing wastewater. They are known for their commitment to excellence. This makes them a top choice for industries needing efficient separation systems.

Why Select Freytech Inc.?

Freytech Inc. offers systems with high separation efficiency. Their oil water separators work well even in tough conditions. Facilities using their systems meet North American hydrocarbon discharge limits easily.

Customers often ask why they should use oil water separator technology. Freytech’s reliability is the answer. Their systems go beyond industry standards, reducing environmental harm and ensuring sustainability.

Customer Testimonials and Success Stories

Customers praise Freytech Inc. for their dedication to satisfaction and efficiency. They talk about how their wastewater processes have improved. This is thanks to Freytech’s innovative solutions.

Many success stories show reduced downtime and better environmental compliance. Businesses looking for reliable partners in oily wastewater management find value in Freytech’s offerings.

Contact Freytech Inc.

If you’re interested in learning about oil water separator benefits, Freytech Inc. is here to help. We offer advanced technology and expertise to support your business. Our goal is to help you maintain compliance and efficiency.

Our team can guide you in choosing the right systems for your needs. Discover how our solutions can improve your operations.

Get in Touch for More Information

For detailed consultations, contact Freytech Inc. directly. We’ll help you understand the benefits of oil water separators. They’re useful in many areas, like industrial waste and stormwater management.

Call Us: +1 (305) 372-1104

Call us at +1 (305) 372-1104 to boost your operational efficiency. Our team is ready to provide insights into oil water separator benefits. We aim to help you manage waste effectively and meet environmental standards.

We’re excited to discuss how we can support your sustainability goals.