Imagine cutting down industrial pollution while boosting your work efficiency. Oil water separators are more than machines; they’re key to better wastewater management in many fields. They separate oil, grease, and hydrocarbons from water, essential in oil and gas, manufacturing, and wastewater treatment. Oil Water Separators Industries and Applications include wastewater management for automotive, manufacturing, and industrial sectors.

These devices help meet environmental standards, reducing the harm caused by industrial activities. This makes them vital in our eco-friendly world today.

Key Takeaways

- Oil water separators play a vital role in reducing environmental harm in key industries.

- Different types of separators achieve varying levels of efficiency, with coalescing plate separators being very effective.

- Applications span across multiple sectors, from petrochemical manufacturing to food and beverage wastewater treatment.

- Regulatory compliance is a driving force behind the adoption of oil water separation technologies.

- The global market for these separators is projected to grow significantly, highlighting increasing industrial reliance on wastewater management solutions.

Understanding Oil Water Separators

Oil water separators are key in treating wastewater before it goes into the environment. They remove hydrocarbons, like oil, from water. These systems use gravity and coalescing technology to work well in many industries.

Definition and Functionality

The way oil water separators work depends on oil droplet size and density. They handle different types of oil in wastewater. Gravity-based separators use gravity to separate oil and water.

Coalescer separators use special media to help oil droplets grow. This makes separating oil more efficient. Clarifiers also help, making the water cleaner and reducing treatment needs.

Importance in Environmental Management

Oil water separators are vital for keeping waterways clean. They stop oil pollutants from harming aquatic life. Following environmental rules is also important to avoid fines.

Industries like steel, food, and power need to separate oil well. This helps them stay sustainable and protect the environment and people’s health.

For more info and solutions on oil water separators, visit Freytech Inc..

Regulatory Standards for Hydrocarbon Discharge

In North America, rules to protect water quality are strict. They set limits on hydrocarbon discharge in industrial wastewater. Facilities must keep oil levels below 10 parts per million (PPM).

To follow these rules, facilities use oil water separators. This helps prevent pollution and keeps people safe.

North American Hydrocarbon Limits

The Vessel Incidental Discharge Act (VIDA) has changed rules for big ships. About 85,000 vessels now follow new discharge rules. This includes fishing boats, passenger ships, and cargo carriers.

These ships must meet EPA’s 2013 standards. The focus is on oil management to reduce pollution.

Compliance with Environmental Regulations

Following environmental rules is key for industries with oil in their wastewater. Oil water separators help meet discharge limits and pass inspections. They show a company’s dedication to the environment.

Good treatment processes avoid fines and improve efficiency. They help meet strict North American standards.

Applications of Oil Water Separators

Oil water separators are key in many industries for managing oily wastewater. They use advanced technology to meet environmental rules and support sustainability. This is true for many industrial uses.

Industries Utilizing Oil Water Separators

Petrochemical plants, manufacturing sites, and the maritime sector use oil water separators a lot. These places deal with wastewater that has a lot of oil. They need to treat it before it goes into the environment. Choosing the right separator is important for each industry’s success.

Wastewater Treatment Facilities

Municipal treatment systems also rely on oil water separators. They handle stormwater and other polluted waters. This ensures pollutants, like oil, are removed before release. Thanks to new technology, these facilities help keep our water and air clean.

Automotive and Transportation Sector

The automotive industry needs oil water separators a lot because of the oily wastewater from car maintenance and washing. Using these separators helps businesses reuse treated water. This meets strict pollution standards and supports eco-friendly practices.

Freytech Inc. Innovations in Separation Technology

Freytech Inc. leads in separation technology, bringing big improvements to oil water separation. They focus on better coalescing technology, making oil droplets merge more efficiently. This helps meet strict environmental rules in many industries.

Enhanced Coalescing Technology

Freytech’s separators use advanced coalescing tech for better oil-water separation. This tech cuts down hydrocarbon levels, meeting North America’s 10 PPM limit. They can even get down to 0.1 PPM for tiny oil bits.

Achieving 5 PPM Separation Efficiency

Freytech’s separators can hit a 5 PPM separation mark. This is key for industries needing to follow strict environmental rules. Their systems help companies move towards sustainable practices, ensuring they can keep running well for a long time.

Reusable Coalescing Media Benefits

Freytech’s separators use reusable coalescing media. This means they work longer, saving money on replacing media often. The media can be cleaned and used for years, keeping efficiency high. This cuts down on downtime, showing Freytech’s benefits in both cost and the environment.

The Role of Oil Skimmers

Oil skimmers are key in removing oil from water sources. Freytech’s oil skimmer uses advanced tech for better separation. It helps industries recover more waste oil, promoting sustainability.

Features of Freytech’s Patented Oil Skimmer

Freytech’s oil skimmer has unique features for oil drainage. It captures oil droplets well and transfers oil automatically. This keeps operations smooth and helps meet discharge rules.

Advantages of Mechanical Draining

Freytech’s mechanical drainage is more efficient than old methods. It works continuously, saving on labor and boosting efficiency. This automated system makes oil skimming more effective in managing wastewater.

Quality of Skimmed Oil

The oil skimmed by Freytech is very pure, at 99.7%. This high-quality oil is valuable for recycling. It saves costs and supports sustainable practices in industries like heavy manufacturing.

Benefits of Efficient Oil Water Separation

Efficient oil water separation brings big wins for the environment and the wallet. It uses cutting-edge tech to help industries go green and save money.

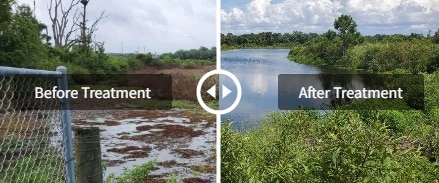

Environmental Protection

Oil water separators are key in fighting pollution. They help clean up wastewater from things like car washes and oil refineries. This keeps our waterways safe and healthy.

Keeping our water clean is vital for all living things. It shows industries care about the planet. This is true for places like construction sites and food factories.

Cost Savings and Recycling Opportunities

Companies that use oil water separators save a lot of money. They don’t have to pay as much to get rid of dirty water. This is a big win for their bottom line.

These systems also let companies reuse oil, turning waste into profit. This makes operations more efficient and profitable. It’s a smart move for both the planet and the business.

Selecting the Right Oil Water Separator

Choosing the right oil water separator is key. It involves understanding the wastewater, contaminants, and rules. This knowledge helps in treating wastewater effectively.

Factors to Consider

Many things affect oil water separator selection. Knowing the oil type and flow rates is important. It ensures the separator works well. Also, treating unique wastewater properly is essential for meeting environmental standards.

Size and Capacity Requirements

The size of the oil water separator is critical. Places with a lot of wastewater need big separators. The right size improves performance and keeps operations running smoothly.

Maintenance and Durability

Maintaining oil water separators is essential. Look for durable materials and easy maintenance access. This helps avoid downtime and saves costs in the long run.

Case Studies: Successful Implementations

Many industries have found success with oil water separators. These case studies show how different sectors have solved their wastewater problems. They also meet strict environmental rules.

A big oil refinery used coalescing plate separators and got 99% separation. This shows a big improvement over old methods.

Real-World Examples of Oil Water Separator Use

An energy generation facility cut down on maintenance and downtime with coalescing plate separators. This technology is cheaper than centrifuges, which are complex and expensive. It’s clear that oil water separators help the environment in many ways.

In the oil and gas industry, separating oily wastewater is key. It helps companies follow rules and improve their image.

Impact on Different Industries

The mining, automotive, and manufacturing sectors have seen benefits from oil water separators. They report lower costs and less need for extra filters. Better separation means fewer contaminants, helping companies stay in line and be green.

With stricter rules, companies are looking for solutions that save money and protect the planet.

Contact Freytech Inc. for Your Needs

If you’re looking to improve wastewater treatment and meet environmental rules, Freytech Inc. is your go-to. Our team is ready to offer oil water separators consultation that fits your needs. We can help you with technical details or find solutions for your operations.

Reach Us Today

Call us at +1 (305) 372-1104 for more information on Freytech. Our customer support team is eager to talk about your oil water separator needs. We’ll help you choose the right system and maintenance plan. Our goal is to give you top-notch service for better wastewater management.

Expertise and Support Information

Freytech is all about quality and following strict standards. Our knowledge helps us suggest the best solutions for various industries. Our services aim to show you the advantages of below-ground separators. This way, you can meet important standards and protect the environment. Reach out to us to learn more and improve your wastewater management.