Have you ever thought about how much oil ends up in our water? It’s a big problem for the environment. Industries like manufacturing, automotive, and food processing need to remove oil from stormwater. They use an Oil Water Separator to Skim Oil from Stormwater.

This isn’t just about following rules. It’s also about keeping operations running smoothly and protecting the environment. Finding ways to remove oil effectively is key. It helps industries stay in line with environmental laws.

Key Takeaways

- Hydrodynamic separators (HDS) play a critical role in efficient stormwater management.

- Design considerations often account for a 1-year, 24-hour storm event, but oversizing can impact efficiency.

- Specific jurisdictions mandate pollutant removal efficiencies from stormwater systems.

- Oil’s lower density makes gravity-based separation an effective method for oil removal.

- Proper maintenance of oil-water separators can extend their operational lifespan significantly.

- Companies can face heavy fines for improper disposal of oily wastewater.

Understanding Stormwater Pollution

Stormwater pollution is a big problem for our local ecosystems and water bodies. Rain and urban runoff carry pollutants like hydrocarbons, fertilizers, and motor oil into storm drains. These pollutants can make water quality worse and harm aquatic life, making it important to manage them.

The Impact of Oil on Water Bodies

Oil spills can destroy aquatic ecosystems. Pollutants like oil and grease can make water unhealthy for fish and other sea creatures. For example, mercury in polluted water can be harmful to people, including children and pregnant women who eat fish from it.

It’s important to manage stormwater pollution to avoid these risks.

Why Skimming Oil is Essential

Skimming oil from stormwater systems is key for industries. Keeping equipment in good shape and following environmental rules helps avoid fines and disasters. Techniques for separating oil and water help industries work better and support efforts to clean up hydrocarbons.

Using best practices, like regular maintenance and oil skimming, can greatly improve water quality. This helps reduce pollution in local waterways.

Regulatory Standards for Oil Discharge

Following rules for oil discharge is essential for staying compliant. In North America, water discharged must not have more than 10 parts per million (PPM) of oil. Following these standards helps keep water and public health safe.

Laws like the Clean Water Act require cities and industries to prevent stormwater pollution. This shows how important it is to take care of our environment.

The Technology Behind Oil Water Separators

Advanced technologies in oil water separators are key to effective stormwater treatment. These devices use gravity and coalescence to separate oil from water. Their efficiency is vital, as they help industries meet strict environmental rules.

A good oil skimming system keeps harmful hydrocarbons out of ecosystems. This ensures compliance and protects water quality.

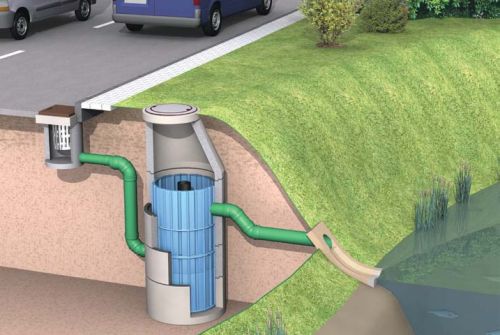

How Oil Water Separators Work

Oil water separators work by using the difference in oil and water densities. Water enters the separator, and gravity makes the oil rise to the top. This lets the clean water flow out from the bottom.

Coalescing media helps by making small oil droplets bigger. This makes it easier to remove them. Together, these methods ensure effective stormwater treatment.

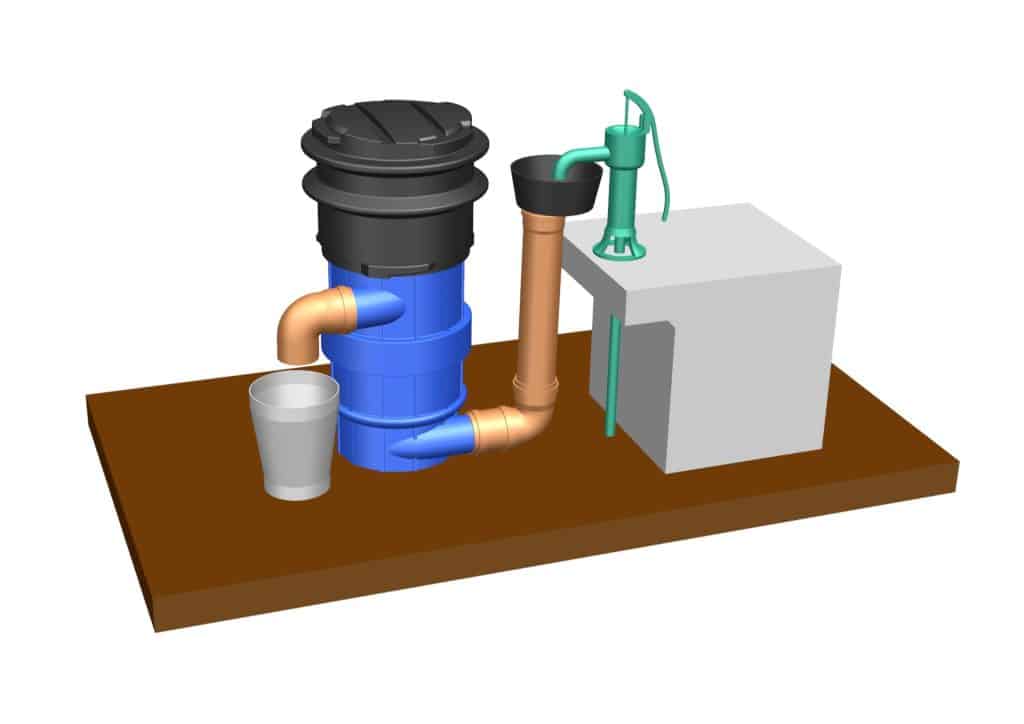

Components of a Freytech Separator

A Freytech separator has important parts that help it work well. The tank is built to handle high flow rates and last long. The inlet design helps water flow smoothly into the chamber.

Coalescing media is key to the separator’s success. It catches small oil particles, improving the system’s performance. This leads to very low oil levels in the water that’s released.

Enhanced Coalescing Technology Explained

New coalescing technology has improved oil separation at Freytech. These advancements allow for separation ratings of 0.1 PPM, meeting or exceeding many standards. Enhanced filtering systems work with traditional separators to catch even the smallest oil droplets.

This technology not only helps meet regulations but also protects water bodies from industrial pollution.

Achieving Efficient Oil Separation

Efficient oil separation is key to keeping water clean and following environmental laws. It helps protect our ecosystems and health. In North America, there are strict rules to reduce oil pollution from stormwater.

New technologies for oil separation are being developed. They meet the tough standards set by law.

North American Hydrocarbon Standards

In North America, there are clear rules for treating wastewater. These rules focus on removing oils and hydrocarbons. Companies need to follow these to prevent oil pollution.

Using advanced solutions like Atlan’s Spillceptor Oil Separator Tanks helps meet these standards. It also supports Environmental Remediation efforts.

Targeting 10 PPM and Beyond

It’s important to keep oil levels below 10 parts per million (PPM). Advanced oil separators can do this. It’s essential for protecting our environment.

If these standards aren’t met, companies face big fines and damage to their reputation. By focusing on hydrocarbon recovery, industries can stay compliant and help water bodies.

Benefits of 0.1 PPM Separation Efficiency

Reaching a separation efficiency of 0.1 PPM has many benefits. It not only meets environmental rules but also lowers the risk of groundwater pollution. Good oil pollution prevention strategies lead to long-term gains.

These include lower costs and a better brand image. Investing in top-notch separators boosts environmental benefits and supports hydrocarbon recovery.

Types of Hydrocarbons Removed

Managing stormwater pollution means knowing about free oil and emulsified oil. Free oil floats on water because it’s less dense. It can be cleaned up using different methods. Emulsified oil is tiny and stays mixed with water, making it harder to remove. Special tools like coalescing separators are needed to get these small droplets.

Free Oil vs. Emulsified Oil

Free oil is easy to skim off the surface during cleanups. But, emulsified oil needs advanced tech, like Freytech’s separators, to separate. Knowing the difference helps in controlling stormwater pollution better.

Common Sources of Oil Pollution

Many industries pollute stormwater with oil. Places like car shops, fuel storage, and industrial areas are big culprits. They cause harmful runoff that pollutes water. Good stormwater management is key to protecting our environment.

Freytech’s Capabilities in Oil Separation

Freytech uses top-notch tech for oil separation. Their systems are great at removing free and emulsified oils. This helps in cleaning up the environment. Freytech’s innovative solutions improve stormwater pollution control in various sectors.

The Role of Coalescing Media

Coalescing Media is key in making Oil Water Separators work better, mainly in Stormwater Treatment Technologies. It helps catch small oil droplets that other methods miss. This leads to cleaner water and helps meet environmental rules.

Properties of Reusable Coalescing Media

Reusable Coalescing Media can handle oils with specific gravities from 0.82 to 0.88. It’s made to get oil levels under 5 PPM. This means it can remove even tiny oil particles, outperforming older methods.

Maintenance and Longevity

Keeping Coalescing Media in good shape is important. Regular cleaning and checking the solids collection chambers are key. This way, the Oil Water Separator works well for longer, meeting standards like CAN/ULC-S656.

Advantages Over Traditional Media

Reusable Coalescing Media beats traditional media in many ways. It’s more efficient and lasts longer, even in tough conditions. It’s also better for the environment, helping industries that care about sustainability.

Optional Oil Skimmer Features

Modern skimmer equipment comes with advanced features to boost efficiency. It includes patented technology for automated oil collection, cutting down on manual work. This automation saves on labor costs and makes the process smoother.

Patented Oil Skimmer Overview

The patented oil skimmer is a breakthrough in hydrocarbon recovery. Its design ensures top-notch oil separation from water. It works well in both above and below-ground settings, thanks to its advanced features.

Automation in Oil Collection

Adding automation to oil skimming systems boosts efficiency. These systems keep an eye on oil extraction 24/7. This helps meet North American hydrocarbon discharge limits of 10 Parts per Million (PPM).

This reduces the need for suction truck services. These services add extra costs based on gallons extracted. So, operations become more affordable.

Ensuring 99.7% Oil Purity

These advanced skimmer systems can achieve up to 99.7% oil purity. Such cleanliness is key for recycling and meeting environmental standards. With better coalescing technology, they can even separate emulsified oil down to 0.1 PPM.

This makes them essential for keeping water clean and maximizing hydrocarbon recovery.

Recycling and Reusing Skimmed Oil

Recycling skimmed oil is good for both the economy and the environment. It turns waste into something valuable, following today’s green practices. Many industries gain from this process.

The Value of Used Oil

Used oil’s worth is often overlooked. Recycling it makes it useful again, saving money. Companies that recycle can cut costs and make money from selling the oil.

Environmental Benefits of Recycling

Recycling used oil helps the planet. It cuts down on landfill waste and saves resources. It also lowers pollution, keeping water clean and people healthy. This supports a greener future.

Cost-Effectiveness of Oil Collection

Collecting oil in a smart way saves money. It’s cheaper than treating it as hazardous waste. The savings can fund community projects or improve waste management tech.

Installation and Setup of Oil Water Separators

Installing oil water separators right is key for top performance and following local rules. A good start is a detailed site check. This lets you tailor the setup to fit the site’s needs and rules.

Site Assessment and Customization

Before installing oil water separators, a full site check is a must. It looks at drainage, soil, and current setups. This helps make the separators work best for that place. It’s a big step in making the system better.

Integration with Existing Systems

Adding oil water separators to existing systems needs to be smooth. Checking current systems makes sure they work well together. This careful step keeps things running smoothly and boosts stormwater management.

Compliance and Installation Guidelines

Following rules and guidelines is critical to meet legal standards. The setup must match local water treatment laws and needed permits. This avoids fines and makes sure the systems clean stormwater as they should.

Maintenance Tips for Oil Water Separators

Keeping oil water separators in good shape is key for top performance and following environmental rules. It’s important to set up a regular check-up schedule. This way, small problems can be caught early, avoiding big repairs or harm to the environment.

Routine Inspections and Cleaning

Do routine checks and cleanings every six months, or more often if needed. Look for signs of wear, leaks, and make sure liquid levels are right. Keeping detailed records of maintenance is a good idea.

Make sure your team knows how to do maintenance tasks. They should understand why regular checks and cleanings are important. Cleaning regularly keeps the separator working well and lasts longer.

Signs of Needing Replacement Parts

Spotting when parts need to be replaced is vital. Watch for odd noises, leaks, or if the separator isn’t working as it should. If performance drops, it might mean parts are failing.

Fixing these problems quickly can save a lot of trouble later. Regular tests help keep an eye on how well the oil and water are being separated.

Strategies for Optimal Performance

To keep your system running at its best, do regular maintenance and make sure oil is lighter than water. Also, don’t forget to do hydrodynamic separator maintenance, like cleaning it out and washing it every year.

Think of maintenance like changing your car’s oil regularly. This way, you avoid problems and keep your oil water separator working efficiently. For more tips, check out maintenance of oil water separators.

Case Studies: Successful Oil Skimming

Freytech’s oil skimming technology has made a big difference in many industries. It shows how well it works and how it helps the environment. Businesses have seen big improvements by using these solutions.

Industries Benefiting from Freytech

Petrochemical, manufacturing, and food processing have all used Freytech. They deal with tough water issues that need special solutions. Thanks to Freytech, some refineries now have zero liquid discharge, showing they care about the environment.

Impact on Local Water Quality

Places that use oil skimming see better water quality. Systems like GL&V/Dorr-Oliver Vacuator remove oil and debris. This makes the water clearer and safer for everyone.

Testimonials from Our Clients

Our clients have great things to say about Freytech. They talk about how it has changed their work for the better. They meet rules and help the planet at the same time.

Contact Freytech Inc. for Your Needs

Starting with Freytech Solutions is easy and clear. Our team is eager to talk about your project needs. We’ll create a solution that meets your oil-water separation needs perfectly.

Whether it’s wastewater at a workshop or a gas station, we design systems to meet high standards. We make sure all systems work well and follow discharge rules.

Getting Started with Freytech Solutions

Working with experts like Freytech Inc. is key for choosing and setting up oil-water separators. Our support ensures you get the best equipment for your work. This keeps you in line with rules and helps keep discharges clean and safe.

This help is vital for getting separation efficiencies of 0.1 PPM and below. It makes sure your discharge is cleaner and safer.

Importance of Professional Support

Call us at +1 (305) 372-1104 for questions and advice. Our team is here to help, making the process easy from start to finish. Contact Us today to see how Freytech can improve your stormwater management.