Ever thought about What are Below Ground Oil Water Separators Used For? or how industries keep their wastewater clean from harmful oil? Below ground oil water separators play a key role in this fight against pollution. They filter out oil and hydrocarbons from contaminated water efficiently. These devices are not just needed by law; they are vital in many fields like automotive and construction.

They are used where oil spills often happen. So, what makes these separators so good at protecting our environment? Let’s explore how they work and why they’re so important.

Key Takeaways

- Below ground oil water separators are vital for managing wastewater in various industries.

- Freytech Inc.’s advanced systems can achieve separation efficiencies as low as 0.1 PPM.

- Compliance with CAN/ULC-S656 standards is essential for effective oil level management.

- These separators can handle up to 1000 Imperial gallons of water per minute.

- Regular maintenance is key to keep them working well and meeting regulations.

- Hydrocarbon decomposition through bioremediation can greatly lower oil content in sludge.

Introduction to Below Ground Oil Water Separators

Below ground oil water separators (OWS) are key to keeping water clean and protecting our environment. They remove oil and grease from wastewater, keeping our waterways safe. Knowing how oil water separators work helps us see their importance in many industries.

Definition of Oil Water Separators

Oil water separators use gravity and buoyancy to separate oil from water. They have chambers where oil floats to the top, making it easy to remove. There are different types, like gravity-based and coalescing plate systems, for various needs.

Purpose and Importance in Environmental Management

These systems are essential for managing our environment, mainly in the automotive, mining, and transportation sectors. They help meet strict environmental rules, avoiding big fines. By working well, they also cut down on water disposal costs, which are a big part of expenses.

For more on oil water separation technologies, check out this link.

How Below Ground Oil Water Separators Work

It’s key to know how below ground oil water separators work for good environmental care. These systems help clean wastewater by separating oil from water. They use the fact that oil is less dense than water, making it float on top.

Mechanism of Oil Separation

The oil separation process starts when wastewater goes into the separator. Oil rises because it’s less dense. Gravity is important in traditional separators. But newer designs use special technology to catch even smaller oil droplets.

This technology, called enhanced coalescing, makes oil separation better. It’s great for places with lots of contaminated water, like oil refineries.

Enhanced Coalescing Technology Explained

Enhanced coalescing technology makes oil water separator maintenance better. It helps remove oil more efficiently, even when there’s not much of it. Keeping the technology clean and checked is important.

If you don’t maintain it well, efficiency can drop by up to 30%. So, knowing how to keep these separators working right is vital. It helps industries follow rules and protect the environment.

Regulatory Standards for Hydrocarbon Discharge

In North America, rules for hydrocarbon discharge are very strict to keep the environment safe. These rules say that hydrocarbon levels in wastewater can’t be more than 10 Parts per Million (PPM). This is key to protect water and the life in it. Companies use oil water separators to follow these strict rules.

Overview of North American Hydrocarbon Limits

The limits in North America aim to cut down oil and pollutants in discharges. Industries, like those in petroleum, use oil water separators to treat waste. This way, they meet the 10 PPM standards. The latest technology in these separators helps treat even tough discharges well.

Importance of Meeting 10 PPM Standards

Following the 10 PPM standards is vital for the environment. It lowers the chance of pollution in stormwater and keeps oceans safe from oil spills. High-efficiency oil water separators help industries meet these standards. This also saves them money by cutting down on treatment costs. For more on reliable solutions, check out the Freytech website.

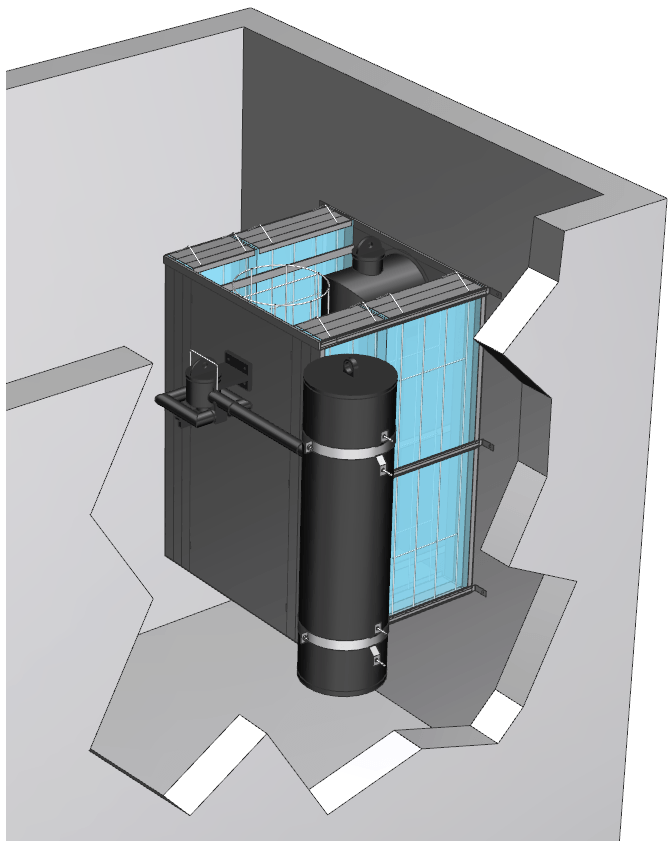

Freytech Inc. Solutions for Oil Water Separation

Freytech Inc. leads in oil water separation solutions. They focus on creating effective below ground separators. These systems use advanced tech to meet high hydrocarbon discharge standards.

Advanced Separation Efficiency of Freytech Systems

Freytech Inc. is dedicated to top-notch oil water separation. Their below ground separators achieve impressive results. They use special coalescing tech to cut oil levels down to 5 PPM.

This high efficiency helps meet North American rules. It also helps industries reduce their environmental footprint.

Achieving 0.1 PPM Separation Efficiency

Freytech Inc. solutions aim to exceed basic standards. Their separators can hit a remarkable 0.1 PPM for emulsified oils. This level is key for industries with oily wastewater, like mining and food processing.

Such precision ensures companies stay green while keeping operations clean.

Types of Hydrocarbons Separated by Freytech

Freytech’s advanced oil water separators are designed to remove various hydrocarbons from wastewater. They filter out common hydrocarbons like motor oil, diesel, gasoline, and jet fuel. These systems keep separation efficiencies below 5 parts per million (PPM), meeting strict environmental standards.

Common Hydrocarbons Removed by Freytech Separators

Freytech’s technology can separate emulsified oils as low as 0.1 PPM. This is key in capturing hydrocarbons that could harm the environment. Freytech systems are used in many places to remove contaminants before they reach wastewater treatment facilities.

Applications in Various Industries

Oil water separators are used in many industries, like automotive, petrochemical, and marine. They are also used in manufacturing and municipal sectors. Freytech separators are essential in places like car washes and equipment maintenance shops.

They offer custom-sized solutions for different flow rates. This ensures they work efficiently and meet federal regulations. Regularly removing harmful materials, these separators protect water quality and the environment.

Features of Freytech Enhanced Coalescing OWS

Freytech enhanced coalescing oil water separators have many features. They are designed to work efficiently and reliably. One key feature is the reusable coalescing media. It offers great benefits in performance and sustainability.

Reusable Coalescing Media Benefits

The reusable coalescing media in Freytech separators makes cleaning easy. Operators can spray wash it to remove dirt. This keeps it working well and saves money on replacements.

Using this media helps lower costs and makes the system last longer.

Maintenance and Cleaning for Longevity

Keeping the oil water separator clean is key to its performance. Users should clean the filter media and check the solids chamber often. If they don’t, the system’s efficiency drops and it wears out faster.

By keeping up with maintenance, Freytech separators can last longer. This ensures they keep working well over time.

The Role of Optional Oil Skimmers

Optional oil skimmers are key to making oil water separators work better. They help remove oils from wastewater, making the oil cleaner. This not only helps the environment but also saves money by cutting down on oil disposal costs.

How Oil Skimmers Improve Efficiency

Oil skimmers help drain oil into special containers. They can take out a lot of oil, leaving it almost pure. This makes oil water separators more efficient, needing less upkeep and working better.

There are different types of oil skimmers. They include belt, disc, tube, and suction skimmers. Each type fits different needs, making them versatile.

Benefits of Collecting 99.7% Pure Separated Oil

Oil skimmers do more than just improve efficiency. They let businesses recycle and reuse oil, turning waste into something valuable. This supports sustainability and helps meet strict environmental laws.

It also means less need to replace coolants, saving money and tools. This leads to big cost savings for companies.

Environmental Impact of Oil Water Separators

Oil water separators are key to improving water quality. They remove harmful hydrocarbons from wastewater. This ensures the water meets strict standards before it’s released into natural bodies of water.

By keeping oil content levels below 15 parts per million, these separators help protect our ecosystem. They also safeguard aquatic life from harmful contamination.

Contributions to Water Quality Improvement

Oil water separators make a big difference in water quality across many industries. They use advanced technology to separate oil and grease from water. This results in clean water that can be safely discharged into municipal sewers.

This not only meets legal requirements but also avoids costly fines and disruptions for businesses.

Benefits of Recycling Separated Oil

Oil water separators also enable the recycling of separated oil. The collected oil can be reused in production or recycled. This greatly reduces waste and supports a circular economy in the oil industry.

This approach not only saves resources but also boosts the environmental benefits of oil water separators. It shows their vital role in sustainable industrial practices.

Contact Freytech Inc. for Your Oil Water Separation Needs

Freytech Inc. is a top choice for businesses looking for reliable oil water separator solutions. They offer high-efficiency systems that meet strict environmental standards. These systems also improve wastewater treatment, supporting sustainable operations.

Why Choose Freytech Inc.?

Freytech Inc. is known for its quality and service. They use advanced technologies to create efficient separation systems. By contacting Freytech, you get to work with a team committed to innovation and expertise.

How to Reach Us: Phone and Inquiries

Interested in learning more about Freytech’s solutions? Need help with your oil water separator needs? Call Freytech Inc. at +1 (305) 372-1104. For more information and to find the right solution for you, visit their contact page.