Have you thought about What Are The Benefits of Using an Air Compressor OWS? or how moisture and oil might be hurting your air compressor? An air compressor oil water separator is key to keeping your compressor running well. It helps remove oil and water, which can save you money and keep your equipment working longer.

These separators are vital for air compressor maintenance. They help your compressor work better and last longer. This means you can save money and avoid expensive repairs.

In today’s world, where things need to work well and fast, using an oil water separator is smart. It can stop up to 90% of damage from moisture. It also makes your tools last 50% longer and can cut energy costs by 15-20%.

Want to make your equipment work better and meet environmental rules? Check out what Freytech Inc. offers in oil water separator technology.

Key Takeaways

- Using an air compressor oil water separator makes your equipment more reliable.

- Managing moisture stops corrosion and expensive breakdowns.

- Removing almost all moisture makes compressed air better quality.

- These separators save energy by cutting down on maintenance and costs.

- They can make your compressed air equipment last 50% longer.

Introduction to Oil Water Separators

Oil water separators are key in many industries. They remove oil from water mixtures. This is important for following environmental rules and keeping water clean.

Definition of Oil Water Separators

These devices separate oil from water using gravity and coalescing. They have several steps to make sure the water is clean. They can make water almost oil-free, with less than 100 ppm oil.

Importance in Industrial Applications

In industries, oil water separators do more than follow rules. They also improve air quality, lower corrosion risks, and boost efficiency. Rules say the water can’t have more than 15 ppm oil.

Overview of the Separation Process

The process mainly uses gravity, based on oil viscosity and size. Higher temperatures help by making the difference in specific gravity bigger. Advanced systems make it even better with features like active monitoring and modular designs.

Compliance with Environmental Regulations

Businesses face a complex world of environmental rules, mainly for hydrocarbon discharge. In North America, the limit for hydrocarbon discharge is 10 Parts per Million (PPM). It’s key to follow these rules to keep licenses and avoid fines. An oil water separator helps meet these standards and can even lower discharge to 5 PPM.

North American Hydrocarbon Discharge Limits

The rules for hydrocarbon discharge in North America are strict. Companies that don’t follow these rules could face big fines, up to $10,000 a day. Oil-water separators are important for keeping hydrocarbon levels low in condensate, ensuring companies follow the rules.

Benefits of Lowering Discharge Levels

Lowering hydrocarbon discharge has many benefits. It helps protect the environment and improves a company’s reputation. By using advanced separation technologies, businesses can cut contaminants in compressor condensate by up to 90%. This also cuts waste disposal costs by 30% and reduces carbon footprint.

Keeping up with regulations also avoids environmental penalties. These penalties can hurt a company’s finances.

Role of Freytech Inc. in Achieving Compliance

Freytech Inc. is key in helping companies follow environmental rules. Their oil water separators are made for high efficiency. They help remove hydrocarbons effectively, meeting North American standards. With Freytech Inc.’s technology, companies can stay compliant, support sustainability, and protect the planet.

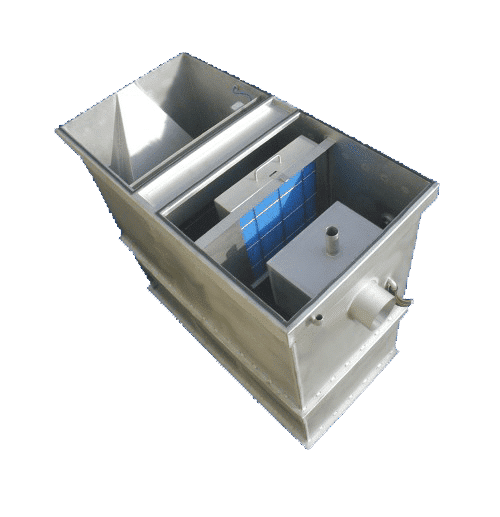

Enhanced Coalescing Technology

Coalescing technology is a big step up in oil water separation. It uses special media to improve separation efficiency. Freytech OWS systems show this with their advanced oil removal from water.

Explanation of Coalescing Technology

This tech helps oil droplets merge into bigger ones. This makes it easier to separate oil from water. The right coalescing media, like borosilicate microfibers, is key for clean separation.

Separation Efficiency Compared to Conventional Methods

Freytech’s coalescing tech can get separation up to 0.1 PPM. This is a big deal in clean industries. New tech, like nanofibers, has made it even better for oil and gas and petrochemicals.

Application of Coalescing Media in the Field

Coalescing media works in many places, like offshore and oil and gas operations. They fit well in different needs, like separating water-hydrocarbon emulsions. Modern coalescers are small and easy to add to systems, saving space and improving efficiency.

Separation of Various Hydrocarbons

Freytech separators are great at separating hydrocarbons. They can handle many types of oils and fuels, like motor oil, diesel, gasoline, and jet fuel. They work very well, getting about 99% of the job done, which is good for the environment.

In places where many types of oils are used, being able to handle different ones is very important. This makes Freytech separators a big help.

Types of Oil and Fuels Separating Capabilities

Freytech separators can manage many kinds of hydrocarbons well. They do a great job, with only a tiny bit of oil left over after they’re done. This means they meet strict environmental rules, helping keep things green.

Importance of Versatility in Industrial Settings

In factories, having equipment that can do many things is key. Freytech separators are made to work well in different situations. They can handle different oils, which helps companies follow rules and work better.

Effectiveness Against Emulsified Oils

Dealing with emulsified oils is hard. But Freytech’s tech makes it easier. They get 95-99% of oil out of hot gas, which is a big plus. This means even tough emulsified oils can be handled well, helping businesses stay green.

Economic Advantages of Using Freytech Separators

In today’s competitive world, using Freytech oil water separators can greatly improve operations. These systems save money and help the environment, making them very efficient.

Cost Savings Through Efficient Oil Recovery

Freytech separators are great at catching and recovering oil from water. This saves businesses a lot of money. They can use the recovered oil instead of buying new, which cuts costs.

The process also reduces waste. This means more oil is saved, which is good for the wallet.

Value of Recycled Oil

Recycled oil is very valuable. With Freytech’s technology, businesses can turn waste oil into something they can sell. This is cheaper than throwing it away, adding to the savings.

Reducing Environmental Remediation Costs

Not following environmental laws can cost a lot. Freytech separators help companies stay in line, saving money. They keep wastewater clean, avoiding fines and lowering cleanup costs.

Maintenance and Usability Features

Freytech’s separators are made for easy maintenance and use. They work well in many industrial places. The coalescing media can be reused, which saves money and is good for the planet.

Reusability of Coalescing Media

The coalescing media in Freytech separators can be spray washed. This makes it last longer. It cuts down on maintenance costs and reduces the need for new media.

Easy Maintenance Practices

Freytech equipment is easy to maintain. Its design makes upkeep simple and quick. This lets operators keep things running smoothly without much hassle.

Longevity of Freytech Equipment

Freytech equipment lasts a long time. It’s made with durable materials and smart designs. This means you won’t need to replace or fix it as often, making it a smart investment.

Optional Oil Skimmer Technology

Oil skimmer technology is key in making oil water separators work better, mainly in industrial areas. Automatic skimming changes how businesses handle oil recovery. It helps make oil cleaner and work more efficiently.

Benefits of Automatic Oil Skimming

Automatic skimming has big benefits, like needing less manual work. It drains oil into a special container, keeping operations running smoothly. This saves time and money for companies, helping them manage resources better.

How the Oil Skimmer Works

The oil skimmer uses a special way to pick up oil from the top of the separation chamber. It has a design with high-density Q-PAC coalescing media. This design helps remove 99.9% of oil droplets over 20 microns.

It works well even when conditions change, thanks to its design. This ensures oil and water are separated effectively.

Purity of Skimmed Oil

The oil skimmed is very clean, with only 0.3% water. The tanks can hold from 300 gallons to 1931 gallons. This means businesses can handle a lot of oil while keeping it very clean.

This clean oil can be reused or disposed of safely. It shows how important good oil skimmer technology is today.

Advantages of Freytech’s Unique Offerings

Freytech leads the industry with its air-water separation technology. Their products aim to boost the efficiency and life of air compression systems. These separators can remove 99% of water vapor and contaminants, bringing big benefits to users.

Comparison with Competitors

Freytech’s technology outshines competitors in separation efficiency. While others offer basic solutions, Freytech’s separators improve oil and water separation by nearly 40%. This means better performance, cost savings, and environmental compliance.

Customer Satisfaction and Trust

Freytech values customer satisfaction highly. Many testimonials show the reliability and effectiveness of their products. Clients see energy savings of 10-30%, showing their trust in Freytech. This commitment to satisfaction strengthens Freytech’s reputation in various industries.

Freytech’s Commitment to Quality

Freytech’s quality is unmatched. Their air-water separators can reduce maintenance costs by up to 25%. This quality extends the life of air compressors and equipment by up to 50%. It shows Freytech’s dedication to reliable, efficient products that support environmental goals.

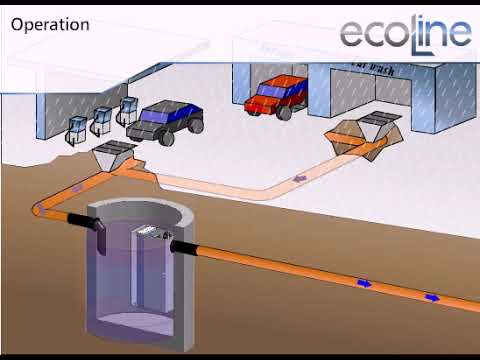

Installation and Integration

Installing oil water separators right is key for them to work well. Freytech gives detailed setup guides to help. This ensures the separator is placed correctly, right after the compressor.

This spot helps separate oil and water better. It keeps the system running smoothly.

Guidelines for Installing an Oil Water Separator

Following specific setup rules is vital for the best oil water separator performance. The right spot boosts separation and system reliability. Freytech stresses the need for careful connections to avoid leaks and keep service going.

Compatibility with Existing Systems

Freytech oil water separators fit well with many systems. They work with different air compressors easily. This makes setup easy, improving efficiency without stopping work.

Integrating with Air Compressors

Connecting oil water separators with air compressors helps manage condensate better. It lowers oil contamination risks in many uses. This meets environmental rules and cuts down on waste disposal costs.

By following Freytech’s guides, businesses can run more sustainably. They save on costs and reduce downtime.

Case Studies and Success Stories

Freytech oil water separators have been used in many industries. They help improve efficiency and cut costs. Many case studies show how these systems solve complex problems.

Places that use Freytech solutions see big improvements. They meet quality and compliance standards better. This shows the real-world value of these advanced technologies.

Real-World Applications of Freytech OWS

Many industries have added Freytech oil water separators to their work.

This upgrade helped them work efficiently in six service bays and a paint shop. These examples show how Freytech systems meet tough needs while saving energy.

Testimonials from Satisfied Customers

Customers are very happy with Freytech oil water separators. They talk about better efficiency and lower maintenance costs. Switching to Freytech has boosted their productivity.

This makes the product even more reliable, thanks to all these success stories.

Proven Results in Various Industries

Case studies show clear benefits from using Freytech technologies. Companies see better compliance and air quality. This proves the systems work well in many industries.

From manufacturing to car restoration, Freytech oil water separators improve performance. They help businesses succeed by boosting their operations.

Conclusion

Freytech oil water separators bring many benefits to air compressors. They help save money by reducing oil loss. This also makes equipment last longer, up to 20% more.

These systems also cut down on maintenance costs by about 15%. They make sure you follow international environmental rules.

Summary of Benefits

Freytech’s technology is top-notch. It catches up to 99% of big oil droplets. This means better air quality and more stable performance.

Using oil water separators can also lower machine failure rates by 25%. This makes your air-powered tools more reliable.

Call to Action for Interested Businesses

If you want to make your business more efficient and green, take action. See how Freytech’s tech can help your operations and profits.

Contact Freytech Inc. for More Information

Want to know more about the benefits and solutions? Call Freytech Inc. at +1 (305) 372-1104. Their team is ready to help you improve your air compression systems.