Ever thought about What Are The Benefits of Using Oil Skimmers? or how we handle oil spills without harming the environment? Oil skimmers are key in this effort. They remove oil from water, helping protect our planet. They also make operations more efficient, last longer, and save money on upkeep.

Using oil skimmers also helps follow environmental laws and saves money. They are very good at cleaning oil from water. This can help avoid big fines for not following rules, making them a smart choice for industries.

Key Takeaways

- Oil skimmers can recover between 30% to 95% of oil, depending on type and conditions.

- They assist in complying with regulatory standards, preventing hefty fines.

- Effective in reducing the environmental impacts of oil spills by lowering affected wildlife risks.

- Enhanced operational efficiency leads to lower maintenance costs and better treatment outcomes.

- Financial savings from recycling collected oil can recoup substantial cleaning costs.

Introduction to Oil Skimmers

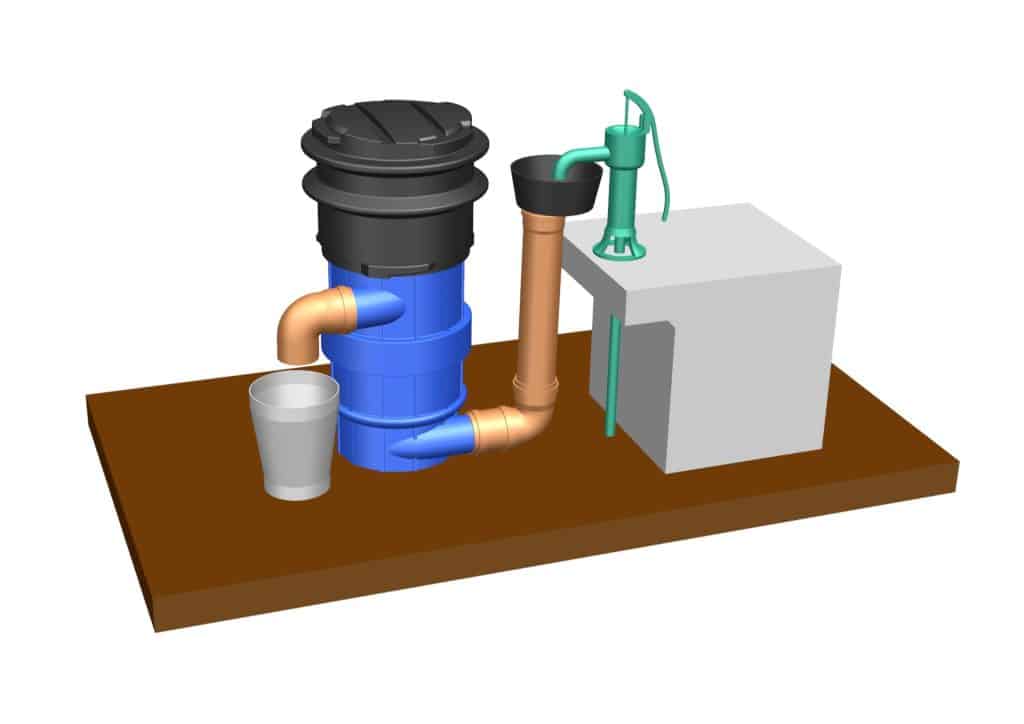

Oil skimmers are key in managing oil spills, mainly in industrial areas. They work by using the natural buoyancy of oil to separate it from water. Knowing how they work is vital for industries facing oil spills. It helps them find good ways to clean up spills and keep fluids in top shape.

Understanding Oil Skimmers

Oil skimmers use the fact that oil is less dense than water to separate it. They come in different types, like belt, tube, and disc skimmers. Each type is made for specific needs.

Using oil skimmers helps keep important fluids clean. This cuts down on maintenance time and boosts work efficiency. Cleaner fluids also mean less energy use and lower costs, making work better.

Importance in Environmental Protection

Oil skimmers are vital for protecting the environment. They help manage fluids well, reducing harmful waste. This helps companies follow strict rules about oil discharge.

Companies using oil skimmers avoid fines and look better in the eyes of the public. Being seen as green can make customers happier. So, oil skimmers are key for both keeping things running smoothly and caring for the planet.

How Oil Skimmers Work

Skimmers are designed to separate oil from water. They use different shapes like belts, disks, and tubes. This design helps them pull oil out because oil is less dense than water.

The Mechanism of Action

Oil skimmers work well in tough waters and industrial places. They pick up oil from the surface, sometimes needing to go back and forth. This is because different oils and conditions require different efforts.

They are key in cleaning up big spills. The U.S. Coast Guard uses them with booms to manage spills effectively.

Enhanced Coalescing Technology Explained

Freytech’s new technology makes oil skimmers better at their job. They can now remove oil down to 5 PPM and emulsified oil down to 0.1 PPM. This shows how modern skimmers can make work easier in many fields.

These systems handle not just oil spills but also other surface pollutants. This makes them very useful. By using these technologies, companies can cut down on waste and follow environmental rules. This saves money and boosts productivity.

Compliance with North American Regulations

Industries that handle hydrocarbons must follow strict rules. These rules set limits on hydrocarbon discharges to protect the environment. Companies must meet the 10 PPM standards to operate responsibly and sustainably.

Meeting Hydrocarbon Discharge Limits

It’s important to separate hydrocarbons effectively to meet discharge limits. Equipment that meets the CAN/ULC-S656 standard is key. Advanced separators from Freytech Inc. can even reach below 5 PPM, greatly reducing environmental risks.

Importance of 10 PPM Standards

Keeping oil levels under 10 PPM is a main goal for industries using oil skimmers. These devices can remove up to 98% of oil in the best cases. Regular maintenance, like cleaning filters and checking solids chambers, keeps separation quality high and ensures compliance.

Freytech Inc.’s Superior Solutions

Freytech Inc. is a leader in environmental protection and industrial efficiency. Their advanced technology excels in separating refined hydrocarbons. This includes both free oils and emulsified oil separation. Their systems help companies meet strict environmental regulations.

Advanced Separation Efficiency

Freytech’s systems can remove up to 90% of hydrocarbon pollutants from water. This reduces contaminants before wastewater treatment, saving costs. Industries see a boost in productivity and capacity with these solutions.

Emulsified Oil Separation Capabilities

Freytech is known for its emulsified oil separation abilities. Their systems ensure 99.7% purity in skimmed oil. This is a huge benefit for industrial operations. These oil skimmers work well in various environments, improving oil removal in plants and facilities.

Types of Hydrocarbons Removed

Oil skimmers are key in removing hydrocarbons from industrial wastewater. They can handle various types of hydrocarbons. This makes them important for protecting the environment and following rules.

Motor Oil and Diesel

Motor oil and diesel are often found in industrial areas. Advanced oil skimmers are great at pulling these heavy substances out of water. This helps prevent harm to the environment and keeps industries within legal limits.

Jet Fuel and Gasoline

Jet fuel and gasoline are tricky because they can catch fire easily. But, systems like belt or disk skimmers are up to the task. They help keep water safe and ensure industries follow the rules.

The Value of Efficient Skimming

Efficient skimming is key to better operations and big savings from skimmed oil. Companies using top-notch oil skimming tech save a lot, mainly on coolant costs. They can cut coolant replacement costs by up to 50% and lower maintenance by 30% by tackling oil issues.

Economic Benefits of Skimmed Oil

Skimmed oil is not just good for the environment; it’s also valuable. High-load operations can remove up to 90% of oil, saving a lot of time and money. This means less downtime and more work done, saving up to 40% in the long run.

Recycling Options for Used Oil

Oil skimmers make recycling easy, turning used oil into something useful. Cleaner water means less need to change it, saving money and water. This is a win for mining and chemical plants, helping them stay green and profitable.

Maintenance and Longevity

Keeping oil skimmers in good shape is key to their success. Regular care boosts their lifespan and keeps processes running smoothly. Freytech’s reusable coalescing media makes cleaning easy, without losing performance.

Reusable Coalescing Media

This smart solution cuts down on waste and saves money. With reusable media, you don’t have to replace it often. It helps companies save and supports green practices.

Simple Spray Washing Procedure

Using a simple spray wash keeps oil skimmers working well. Clean media means no clogs and better performance. This care routine helps your equipment last longer and keeps oil out of water.

Automatic and Mechanical Features

Skimmers have seen big changes thanks to new tech. They now work better at pulling oil out of water. This makes them more useful in many fields.

They are designed to handle different oils and work well in various places. This means they can do their job better.

Benefits of Patented Oil Skimmers

Freytech’s tech is special because it automatically moves oil to a container. This means less work for people, making oil collection easier. It also makes sure oil is collected safely and without spills.

This leads to safer work places and better following of environmental rules. It’s a win for everyone.

Pure Oil Collection Process

The pure oil collection is key to good oil skimming. New designs let oil be taken out very cleanly. Some systems get oil up to 99.7% pure, without any water.

This clean oil can be recycled or reused. It helps reduce waste and is good for the planet. Using these skimmers helps industries be greener and work better.

Conclusion: The Case for Oil Skimmers

Oil skimmers are becoming more important in many industries. They help improve work efficiency, follow rules, and save money. They remove unwanted oils, making coolants work better by up to 30% and cutting bacteria in fluids by about 50%.

This leads to machines working better, sometimes up to 25% more efficiently.

Summarizing Key Benefits

Oil skimmers also help the environment a lot. They stop polluted fluids from getting into waterways, helping industries be more sustainable. Companies using these tools see less waste by about 20% and keep fluids clean for food and drink production.

This shows that investing in oil skimmers makes the environment cleaner and helps protect our natural resources.

Final Thoughts on Environmental Impact

Considering these points, it’s clear that businesses should move towards greener operations. Using oil skimmers can lead to financial gains, with a return on investment of 12% to 30%. It also helps the environment a lot.

Companies like Freytech Inc. are leading the way with their oil skimmer technology. This technology is key for making industries more efficient and sustainable. For more details on how these systems can meet your needs, check out advanced oil extraction solutions.