Have you thought about What Are The common Issues With Above Ground OWS? or how above ground oil water separators (OWS) might affect your environmental rules? These systems are key for managing oily water in industries like oil and gas, marine, and automotive. It’s important to look at the common problems with OWS that can hurt efficiency and follow rules.

This article talks about the usual OWS issues. These include not separating well, maintenance problems, and the need to follow environmental laws. Knowing these issues helps make these systems work better and meet strict rules from places like MARPOL Annex I.

Key Takeaways

- Above ground OWS systems face significant operational challenges, impacting their effectiveness.

- Inefficient separation can lead to non-compliance with environmental regulations.

- Regular maintenance is key to keep OWS systems working right.

- Common issues include hard-to-handle emulsions and strict limits from regulatory bodies.

- Following standards can avoid expensive fines and environmental problems.

Understanding Above Ground Oil Water Separators (OWS)

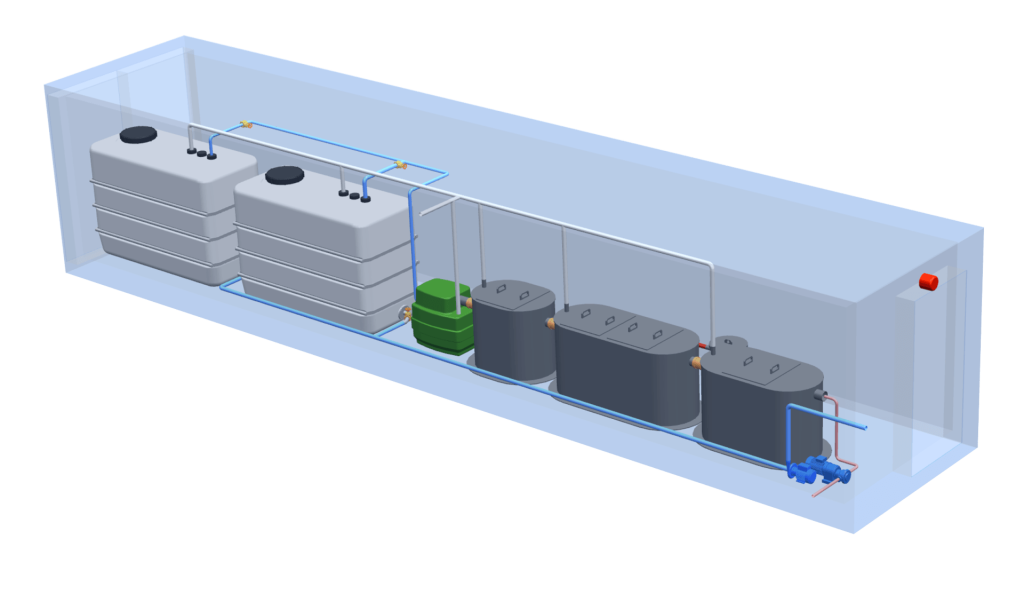

An oil water separator (OWS) is key in treating wastewater. It’s made to remove oils and hydrocarbons from water. Above ground OWS are easier to maintain and monitor than those below ground. They are great for industries that need to follow environmental rules.

What is an Oil Water Separator?

An oil water separator’s main job is to remove oils, greases, and contaminants from wastewater. This is important for keeping water clean and following laws. The Clean Water Act requires industries to use these systems to stop oil from getting into waterways.

Benefits of Above Ground OWS

Using above ground OWS has many advantages. They are simpler to keep up with, making it easier to do maintenance and checks. This can save money and help the environment, making them a smart choice for companies dealing with wastewater.

Common Types of Above Ground OWS

There are many types of oil water separators for different needs. Gravity separators use oil’s natural buoyancy to separate it. Coalescing plate separators increase the surface area for oil droplets. Centrifugal separators use fast rotation to separate oil and water. Each type is designed to work best for specific industries.

Key Issues with Above Ground OWS

Above ground Oil Water Separators (OWS) face many challenges. These issues can greatly affect their performance. It’s important to understand these problems to fix them and keep systems running well.

Inefficient Separation Capabilities

One big problem is when OWS can’t separate oil and water well. This can lead to water that has too much oil, which is bad for the environment and can cause legal issues. It’s key to check these systems often to avoid these problems.

Maintenance Challenges

Keeping above ground OWS in good shape is hard. They need regular checks to work right. If these checks don’t happen, the systems can get worse. Fixing these issues takes a lot of effort and time to keep them running smoothly.

Environmental Compliance Issues

It’s very important for facilities with OWS to follow environmental rules. Not following these rules can cause big fines and harm the environment. Companies need to stay on top of these rules by updating their technology and following best practices.

Impact of Poor Separation Efficiency

Poor separation efficiency in oil-water separators can have big effects on industries and the environment. One major issue is the risk of exceeding hydrocarbon discharge limits. Regulatory bodies set strict standards, like the 10 PPM standards, for industrial operations.

When these limits are broken, facilities might face big fines and even shutdowns.

Consequences of Exceeding Hydrocarbon Limits

When industries don’t keep up with separation efficiency, they risk higher hydrocarbon discharge levels. This can lead to big problems with regulations and increase the chance of environmental disasters like oil spills.

Such incidents can harm aquatic ecosystems a lot. This adds to the legal and financial troubles for the companies involved.

Importance of Meeting 10 PPM Standards

Following the 10 PPM standards is key for any facility using oil-water separators. Keeping up with regular checks and maintenance helps keep separation working well. Companies that focus on these standards avoid big fines and show they care about the environment.

This approach helps them stay sustainable and responsible. It shows they are committed to following rules and protecting the planet.

Selecting an Effective Oil Water Separator

Choosing the right oil water separator is key. You need to look at how well it separates oil from water. A good separator keeps oil levels low, which is better for the environment.

It’s also important to think about how easy it is to maintain. Easy access and service help keep things running smoothly.

Criteria for Choosing an OWS

When picking an OWS, look at its efficiency and how it meets standards. For example, it should handle oil levels below 10 PPM. Some separators, like those from Freytech, can get levels as low as 0.1 PPM.

The right choice should match your needs and follow environmental rules.

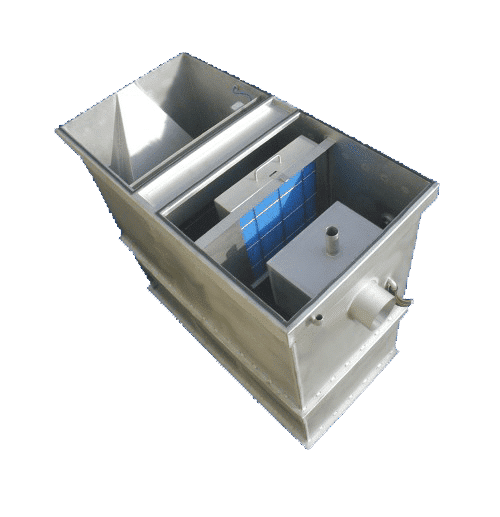

The Role of Coalescing Technology

Coalescing technology is a big help in oil water separation. It uses special media to make oil droplets bigger. This makes the separation process more effective.

Using this technology means cleaner water discharge. Freytech’s separators can get oil purity up to 99.7%, showing how good coalescing can be. For more info, check out Freytech Inc..

Freytech Solutions for Common Issues

Freytech Inc. offers advanced solutions for common problems with above-ground oil water separators (OWS). Their systems use enhanced coalescing technology for better separation. This technology helps businesses meet environmental regulations by achieving 5 PPM separation efficiency.

Enhanced Coalescing Technology Overview

The enhanced coalescing technology in Freytech OWS solutions tackles tough emulsified oils. It improves the separation process, catching trace hydrocarbons that others miss. This means businesses can stay within legal limits and reduce their environmental impact.

Achieving 5 PPM Separation Efficiency

Freytech OWS solutions aim for 5 PPM separation efficiency, going beyond the usual standards. This is key in places where strict discharge limits, like MARPOL Annex I, apply. Their advanced systems ensure oily water meets or exceeds regulations before it’s released.

Reusable Coalescing Media Benefits

Using reusable coalescing media in oil-water separators boosts efficiency. It offers a big advantage in how long it lasts. This means you don’t have to replace it as often.

This leads to less downtime. You need to do maintenance less often because the media lasts longer.

Performance Longevity

Reusable coalescing media makes separation more efficient. It also lasts longer with each use. This is thanks to regular cleaning and upkeep.

It keeps costs low. This is great for places that need to handle oily wastewater from vehicles and machinery.

Cost-Effectiveness of Reusable Media

Reusable coalescing media is cost-effective. It saves money by reducing the need to buy new media. This lets businesses spend on other important things.

It’s also good for places that have to follow strict wastewater rules. Not following these rules can cost up to $100,000. Choosing reusable media is a smart move for saving money and being green.

The Value of Efficient Oil Skimming

Efficient oil skimming is key in managing oily water and following environmental rules. Using advanced tech, like Freytech’s patented oil skimmer, makes collecting oil easier. This tech helps achieve a purity level of 99.7%, greatly reducing water pollution.

Integrating Patented Oil Skimmer

The oil skimmer’s benefits include easier operations and better oil removal. It makes the skimming process simpler and captures more oil. This automation saves time and labor, letting facilities use resources better.

Environmental and Economic Benefits of Skimming

The economic gains from oil skimming are huge. It turns waste into a valuable resource that can be recycled for free. This supports green initiatives and helps companies meet tough environmental standards. It shows how important good oily water management is.

Proper Maintenance Practices for OWS

Effective OWS maintenance is key for their long-term performance. Regular checks help spot problems early, like clogs and operational issues. It’s also important to clean them regularly to keep them working well.

Routine Inspection and Cleaning

Regular inspections should look at how well the system separates, its mechanical parts, and overall health. Cleaning schedules should include deep cleans to remove sludge. This keeps the system running smoothly and avoids environmental problems.

Importance of Regularly Scheduled Maintenance

Regular maintenance is vital for OWS systems. It helps catch small issues before they get big. This keeps the system in line with environmental rules and makes it more efficient, saving costs.

Conclusion: Improving OWS Performance

Improving the efficiency of above ground oil water separators (OWS) is key for good oily water management. Upgrading to Freytech solutions can greatly boost OWS performance. They use the latest technology for better separation, cutting down on maintenance costs and meeting strict environmental rules.

The Case for Upgrading to Freytech Solutions

Freytech’s new solutions improve separation and make maintenance cheaper. By going with Freytech, facilities see big gains in efficiency and lower environmental harm. This move shows a smart way to handle oily water, helping companies follow rules without losing effectiveness.

Contact Freytech Inc. for Expert Advice

For custom solutions and expert advice on oily water treatment, contact Freytech Inc. at +1 (305) 372-1104. The team at Freytech is ready to help with any questions. They’ll give you tips to make your oily water management systems better, helping you reach your sustainability goals and improve OWS performance.