Ever thought about What Are the Environmental Benefits of Above Ground OWS? or how industries can reduce their environmental impact? Above ground oil-water separators (OWS) offer a great solution.

Above ground OWS are key in cutting down on pollution from hydrocarbon discharges. They remove oil, grease, and other harmful stuff from wastewater. This is vital for keeping soil and groundwater clean.

Freytech Inc. leads in this field, with separators that can separate contaminants as low as 0.1 Parts per Million (PPM). These systems help industries meet and even beat the North American limit of 10 PPM for hydrocarbon discharge. This means cleaner water goes back into our ecosystems, helping wildlife and ensuring sustainability.

In this article, we’ll look at the environmental perks of above ground OWS. We’ll see why these green solutions are a must for today’s industries.

Key Takeaways

- Above ground OWS is vital for reducing hydrocarbon pollution.

- Freytech’s technologies achieve separation efficiency as low as 0.1 PPM.

- Proper maintenance of OWS prevents sewer discharge violations.

- Ecosystem health improves with cleaner water discharge.

- These systems offer economic advantages through reduced sludge cleanup frequency.

Introduction to Above Ground OWS

Oil-water separators (OWS) are key in protecting our environment. They help manage water pollution from industrial activities. These systems remove hydrocarbons from water, making sure they meet strict discharge rules.

Many industries, like mechanical workshops and gas stations, use OWS. They do this to keep water quality high in their operations.

Definition and Purpose of OWS

An above ground OWS separates oil and water using gravity and coalescing methods. It removes oil from wastewater, helping it meet standards like MARPOL Annex I. This standard limits oil in bilge water to less than 15 parts per million (ppm).

The success of these separators in reaching such low levels shows their vital role. They are essential for the purpose of OWS.

Importance of Water Quality

Water quality is critical in today’s industrial world. The right operation of an above ground OWS ensures effluent discharge quality. This prevents pollutants from harming our water bodies.

By following environmental rules, companies help our ecosystem and protect public health. Keeping these systems well-maintained is key to their performance and reducing harm to the environment.

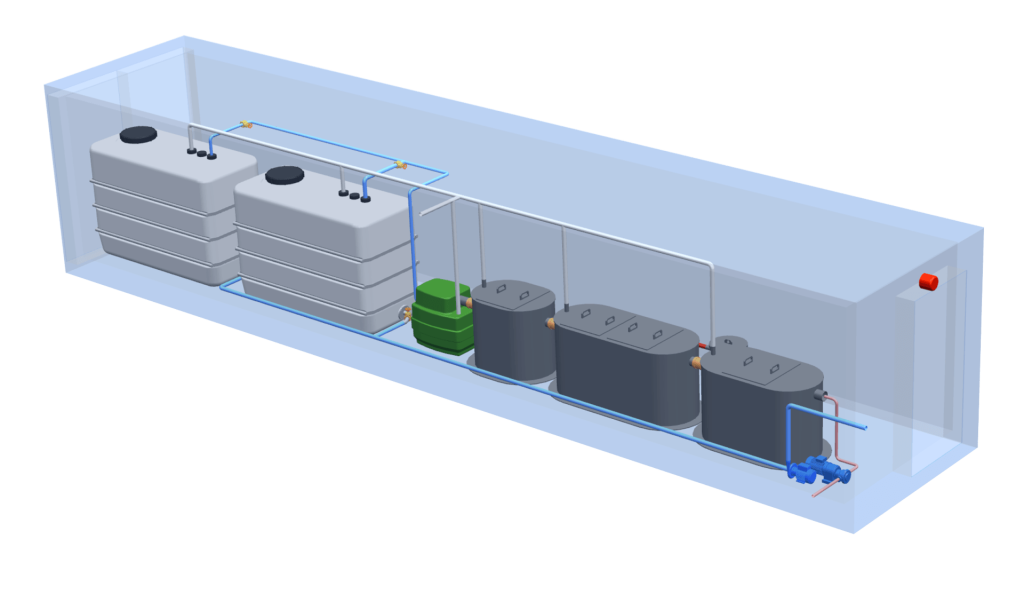

Overview of Freytech Inc.

Freytech Inc. is a leader in oil-water separator design and manufacturing. They focus on making above ground OWS that go beyond compliance standards. Their goal is to offer eco-friendly solutions and innovative products.

With advanced technology, Freytech Inc. ensures efficient oil recovery and water treatment. This helps industries maintain the importance of water quality.

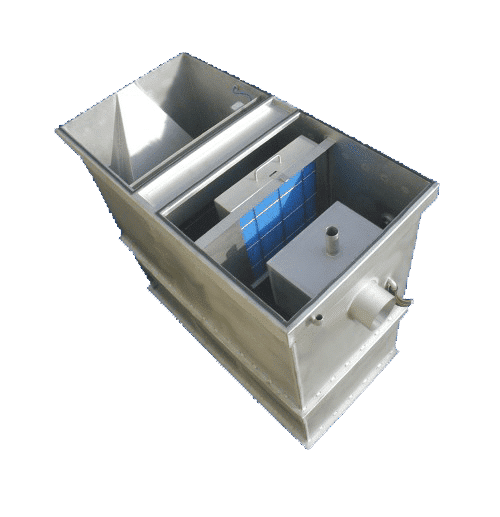

Enhanced Coalescing Technology

In the world of wastewater management, enhanced coalescing technology is key. It helps improve how oil is separated from water. This tech works by merging oil droplets into bigger ones, making them easier to separate.

How Coalescing Works

Coalescing technology uses special media to join small oil droplets into bigger ones. This makes it simpler to separate oil from water. It makes oil-water separators work better, leading to cleaner water and less harm to the environment.

Separation Efficiency Explained

The success of enhanced coalescing technology shows in its separation efficiency. It can reach up to 5 PPM, beating many old methods. These old ways struggle to meet standards, but this tech does it faster and more reliably.

Comparison with Traditional Methods

Old methods often just use gravity, which is slow and not very effective. They might not remove enough oil to meet environmental rules. But, enhanced coalescing technology is better. It offers higher efficiency and cuts down oil in water, protecting our water and nature.

Meeting Environmental Regulations

Following environmental rules is key for industries that work with hydrocarbons. Knowing the North American hydrocarbon discharge limits is vital. These limits set the maximum amount of hydrocarbons allowed in water, often as low as 10 PPM.

Companies using Freytech’s OWS technology can do even better. They usually cut discharge levels to just 5 PPM. This greatly reduces the harm to the environment.

Understanding North American Hydrocarbon Discharge Limits

North American hydrocarbon discharge limits are set to keep water quality high and protect nature. Different areas have their own rules for how much hydrocarbon is allowed in wastewater. Following these rules is critical, as breaking them can cost around $100,000.

Big industries like mining and automotive need to watch these limits closely. They handle a lot of wastewater and can face big fines if they don’t meet the rules.

The Role of OWS in Compliance

Oil-water separators (OWS) are key to following OWS rules. They clean wastewater, making sure it meets or goes beyond what’s required. Using automated tech helps businesses work better and spend less time checking things manually.

It’s important to check OWS systems often. If you don’t, you might have to stop work and spend a lot of money on repairs.

Benefits of Exceeding Regulatory Standards

Going beyond what’s required can really help a company. It shows you care about the environment and are responsible. This can make people trust your brand more and improve how others see you.

By adding recycling and saving water, you can also save money. This can make your business more efficient and cut down on costs.

Separation of Various Hydrocarbons

Technology for oil water separators (OWS) has improved a lot. These systems can now separate different types of hydrocarbons well. They help keep our environment safe and protect water quality.

Types of Hydrocarbons Detected

Advanced separators, like those from Freytech Inc., can spot many hydrocarbons. They can find motor oil, diesel, gasoline, jet fuel, and more. It’s key to manage these hydrocarbons well in many industries.

Being able to find specific hydrocarbons is vital. It helps with waste management and keeps our environment safe.

Specifics on Oil Separation Capabilities

Freytech’s OWS can separate oil levels to below 5 PPM. This is way under the 15 PPM limit set by regulations. They can handle up to 2000 PPM of oil and can even get levels as low as 0.1 PPM.

This high performance is very important. It’s needed in places like car repair shops and factories. These places have to manage oily wastewater very carefully.

Importance for Industries

It’s very important for industries to use good oil separation systems. Using these advanced separators helps companies follow the US EPA’s Clean Water Act. This way, they avoid big fines for not following environmental rules.

Also, keeping hydrocarbons separated right helps prevent pollution. It keeps our soil and groundwater clean. This is good for the environment and helps industries be more sustainable.

Contact Freytech Inc. at +1 (305) 372-1104 for solutions. Start your journey to a greener future.

Reusable Coalescing Media

Reusable coalescing media is changing how we handle oil-water separation. It makes systems more sustainable and cost-effective. This technology extends the life of separation systems, reducing the need for frequent replacements.

Environmental Impact of Reusability

Using reusable coalescing media cuts down on waste. This approach helps the environment by reducing the amount of waste we generate. It also means these systems can work well for years, needing only occasional cleaning.

Maintenance and Longevity

Maintaining reusable coalescing media is easy, which means systems last longer. These media have a large surface area and a high void volume. This setup optimizes flow and reduces the need for upkeep.

Economic Benefits for Businesses

Businesses save money by using reusable coalescing media. It lowers the cost of managing wastewater. This allows companies to use their resources more wisely, helping both the environment and their bottom line.

Automatic Oil Skimmer Features

The automatic oil skimmer is key in modern water treatment systems. It’s designed to remove oils from water efficiently. This technology helps solve big environmental problems.

Functionality of the Patented Oil Skimmer

This skimmer uses new designs to make oil removal easier. It works all the time, cutting down on breaks and keeping oil separation strong. It also needs less human help, making it more efficient.

Purity Levels Achieved with Skimming

The skimmer’s success means water can be very clean. It can get up to 99.9% clean, making oil good for recycling. This is great for companies that want to follow strict environmental rules and be more sustainable.

Impacts on Waste Management

Using an automatic oil skimmer changes how companies manage waste. It cuts down on oil in water, saving money and reducing harm to the environment. This helps companies use resources better and follow green waste management plans.

Recycling and Reusing Separated Oil

Oil separated from wastewater is more than waste; it’s a valuable resource. Recycling this oil turns it into something useful. Companies can use it in production or sell it to make money.

Value of Efficiently Skimmed Oil

Skimmed oil is very valuable for businesses. It helps them use less raw materials. This supports sustainability and the circular economy.

Turning waste into reusable material is good for business. It shows the benefits of recycling.

Recycling Processes and Benefits

Recycling oil lowers production costs and helps the environment. It reduces the need for raw materials. This is good for the planet.

Using these recycling methods makes operations cleaner. It also cuts down on hazardous waste. This shows a company’s commitment to being green.

Cost Implications for Companies

Recycling oil is good for a company’s wallet. It lowers treatment costs and avoids fines. Using technology like the oil water separator makes things more efficient. This saves money and helps the environment.

Contact Freytech Inc. at +1 (305) 372-1104 for solutions. Start your journey to a greener future.

Contribution to Wildlife and Ecosystems

Oil pollution is a big threat to ecosystems. It blocks sunlight from reaching plants in water, stopping photosynthesis. This is key for life in these places. Also, oil pollution builds up in food chains, harming biodiversity and upsetting the balance of ecosystems.

Impact of Oil Pollution on Ecosystems

Oil pollution has many bad effects on ecosystems. It harms fish and other sea creatures, making it hard for them to reproduce and survive. This damage affects not just species but the whole ecosystem. It can also hurt food security and the services ecosystems give us.

Benefits of Cleaner Water for Wildlife

Clean water is essential for healthy wildlife. Solutions like Freytech’s Oil Water Separators help remove pollutants. This makes water better for fish and other sea creatures.

Good water quality helps wildlife deal with environmental changes. It also supports more species. Healthy places mean more fish, birds, and other animals.

Long-term Environmental Sustainability

Working towards sustainability means tackling oil pollution early. Businesses can use technology to stop pollutants. This helps keep the environment healthy for future generations.

By focusing on clean water and sustainability, we protect wildlife. We also make ecosystems strong and diverse. This is good for the planet.

Case Studies and Success Stories

Freytech OWS has made big strides in many industries. It has shown its worth through detailed case studies. Automotive repair shops, gas stations, and manufacturing facilities have all used Freytech’s solutions.

These oil-water separators have made water quality better. They also help meet environmental standards.

Industries Using Freytech OWS

Many industries have chosen Freytech OWS to solve their environmental problems. Automotive repair shops now have cleaner wastewater. Gas stations have less hydrocarbon in their runoff.

Manufacturing facilities have also seen improvements. They’ve adopted this new technology to better their environmental scores.

Measurable Environmental Benefits Achieved

Case studies show the big environmental wins with Freytech OWS. These units have cut down hydrocarbon levels a lot. This makes water quality better overall.

The good effects go beyond just meeting rules. They help make ecosystems healthier and support sustainable practices.

Testimonials from Stakeholders

People who use Freytech OWS share their positive experiences. They talk about how reliable and effective these systems are. They help reach sustainability goals.

Feedback shows a strong commitment to being responsible. It also proves that oil-water separation works well. For more info, visit their website.

Conclusion: The Future of OWS Technology

OWS technology is key to better environmental protection. New systems will make water cleaner. Freytech Inc. leads in this area, pushing for top environmental standards.

Innovations on the Horizon

Businesses are now seeing the value of green practices. OWS tech will get better, fitting into current systems. This move supports Freytech Inc.’s environmental goals.

Commitment to Environmental Protection

Companies must act to protect the environment. Freytech Inc. is leading with green tech. This shows a strong need for better water solutions.

Call to Action: Contact Freytech Inc. for More Information

More companies want to treat water better and care for the environment. Freytech’s tech can help. Contact Freytech Inc. at +1 (305) 372-1104 for solutions. Start your journey to a greener future.