Ever wondered What Are The Types of Oil Skimmers? or how industries keep our water clean from oil spills? What makes oil skimmers work? These devices are key in many fields, from making things to working on the sea. They help remove oil from water surfaces.

Knowing about the different oil skimmers helps us understand how they work. It also shows us their important role in keeping our environment safe. In this article, we’ll explore the various types of oil skimmers. We’ll see what makes them special and why they’re important for a greener future.

Key Takeaways

- Oil skimmers are essential for effective oil removal in multiple industries.

- The effectiveness of skimmers can vary widely based on their type and operational design.

- Weir skimmers generally have higher oil and water removal rates compared to oleophilic skimmers.

- Common oil skimmer types include mechanical, floating, and vacuum skimmers.

- Oil skimmers contribute to environmental protection by preventing harmful spills in marine environments.

- Different applications greatly influence the choice of oil skimmer technology.

- An informed choice of oil skimmer can significantly enhance oil recovery efficiency and compliance with regulations.

Introduction to Oil Skimmers

Oil skimmers are key to keeping industrial areas clean and meeting environmental rules. Knowing what an oil skimmer is helps us see how they work. They remove oil from water, which is important for places like factories, oil fields, and water treatment plants.

Definition and Purpose

An oil skimmer is a tool made to pull oil off the surface of water. They make work areas cleaner and help machines last longer. This is good for places like CNC coolant systems. Using oil skimmers also helps companies follow rules about how to handle oil.

Importance of Oil Skimming

Oil skimming is very important. It helps machines last longer and saves money. It also means less need to replace coolants, which saves money too. Using oil skimmers can also prevent big fines for not following environmental rules.

Applications in Industry

Oil skimmers are used in many ways across different industries. In factories, they keep coolant and cutting fluids clean, helping machines work better. They also improve washing systems and keep quenching fluids in heat treatment processes working right. Putting oil skimmers in the right places makes them more effective.

Types of Oil Skimmers

It’s key to know the different oil skimmer types for effective oil recovery. Each type has its own purpose and works in unique ways. They are designed for different environments and types of oil.

Mechanical Oil Skimmers

Mechanical oil skimmers use physical methods to remove oil from water. There are many designs, like belt, drum, and disc skimmers. Belt skimmers are good for thick oils but need regular upkeep.

Drum skimmers are great for medium-viscosity oils and are often used in industries. Disc skimmers are durable and reliable for medium viscosity oils. But, they work best in shallower tanks. Tube skimmers cover more area but struggle in deep water.

Floating Oil Skimmers

Floating oil skimmers are essential for cleaning oil from the surface of oceans. They use gravity to attract and skim off oil, taking in less water. For example, floating weir skimmers are good at removing contaminants but need complex setups.

Suction skimmers are portable and work well in calm waters during spills. They collect both oil and water, making them good for small-scale operations.

Vacuum Oil Skimmers

Vacuum oil skimmers use suction to remove both heavy and light oils. They are versatile and work well in tough conditions. For example, centrifuge skimmers are great at separating emulsified oils and are used in many industries.

Brush and sponge skimmers are efficient for medium viscosity oils. They can be adjusted for different sizes or minimal solvents. Choosing the right oil skimmer depends on the operation’s size, oil type, and environment.

Features of Effective Oil Skimmers

Effective oil skimmers are key in keeping industries running smoothly. They focus on three main areas: how well they separate oil, how easy they are to maintain, and their impact on the environment.

Separation Efficiency

How well an oil skimmer separates oil from water is critical. Top models can remove up to 99% of oil. This keeps coolant clean and prevents harmful bacteria growth, which can cause machine corrosion.

By removing oil continuously, these skimmers boost manufacturing efficiency. They help keep production running at its best by avoiding slowdowns.

Maintenance Requirements

Maintaining oil skimmers is vital for their long-term performance. Easy-to-maintain models can cut maintenance costs by 20-30% compared to older methods. Regular upkeep stops clogs and protects machines, ensuring safety and efficiency.

Automating oil skimming also cuts downtime. This lets workers focus on other important tasks.

Environmental Impact

The environmental benefits of oil skimmers are significant. They help meet strict water discharge standards, keeping oil pollution low. This protects water and air quality, and reduces health risks for workers.

Advantages of Using Oil Skimmers

Oil skimmers offer many benefits for industrial use. They help meet environmental standards by following oil skimmer regulations. This way, companies can avoid big fines, which can be up to $50,000.

Compliance with Regulations

Oil skimmers help businesses follow strict environmental laws. These laws limit how much oil can be released into the environment. By using oil skimmers, companies can meet these standards and protect the environment.

Cost-Effectiveness

Oil skimmers are also good for the wallet. They can cut down on maintenance costs by up to 30%. This is because they prevent equipment problems and keep things running smoothly. Companies also save on chemical treatments, with savings of 20% to 50%.

These savings can pay off in just 6-12 months. This makes oil skimmers a smart choice for those watching their budget.

Resource Recovery

Oil skimmers do more than just save money and follow rules. They also help recover valuable resources. By removing up to 95% of surface oil, they make it possible to recycle and reuse oils.

This recycling supports sustainability goals. It turns waste into something useful. To learn more about how oil skimmers can change your operations, check out oil extraction solutions.

Freytech’s Enhanced Coalescing Technology

Freytech Inc. has made a big leap with its new coalescing technology. It’s designed to improve the oil-water separation process. This innovation is key for industries that must follow strict environmental rules.

Overview of Technology

The Freytech oil skimming tech uses advanced coalescing media. It catches tiny oil droplets in water. This tech makes sure wastewater meets hydrocarbon discharge limits.

It helps facilities reduce their environmental impact. At the same time, it boosts their operational efficiency. This is thanks to Freytech’s cutting-edge solution.

Separation Performance

Freytech’s system can separate up to 0.1 PPM of emulsified oil. This is a big improvement over older methods that often can’t meet strict standards. It also reliably separates non-emulsified oils below 5 PPM.

This makes it a top choice for many applications. It offers effective solutions for different needs.

Comparison with Traditional Methods

Freytech’s technology beats traditional oil skimming in many ways. Older methods might not catch oil droplets as well. This can lead to more contamination in discharge.

Using Freytech’s tech, facilities can cut down their ecological footprint. They can also improve their oil separation performance a lot.

The Role of Oil Water Separators

In industries where oil and grease in water is a problem, oil water separators are key. They help remove hydrocarbons from wastewater before it’s released or treated. Knowing how they work is important for managing hydrocarbons well.

How They Work

Oil water separators use gravity and coalescence to work. When oil and water mix enters the separator, oil floats up and water goes down. This makes it easy to take out the oil, leaving cleaner water to go into the environment.

Types of Oil Water Separators

There are many types of oil separators for different needs. Gravity separators use oil’s natural buoyancy for separation. Coalescing separators help oil droplets merge, making them easier to remove. Each type is designed for specific industries, ensuring they follow strict rules.

Importance in Hydrocarbon Management

Managing hydrocarbons well is vital in many industries. Following regulations is not just a suggestion but a law in many places. Not following rules can lead to big fines and legal trouble. Oil water separators help avoid these problems, keeping operations running smoothly and protecting water sources.

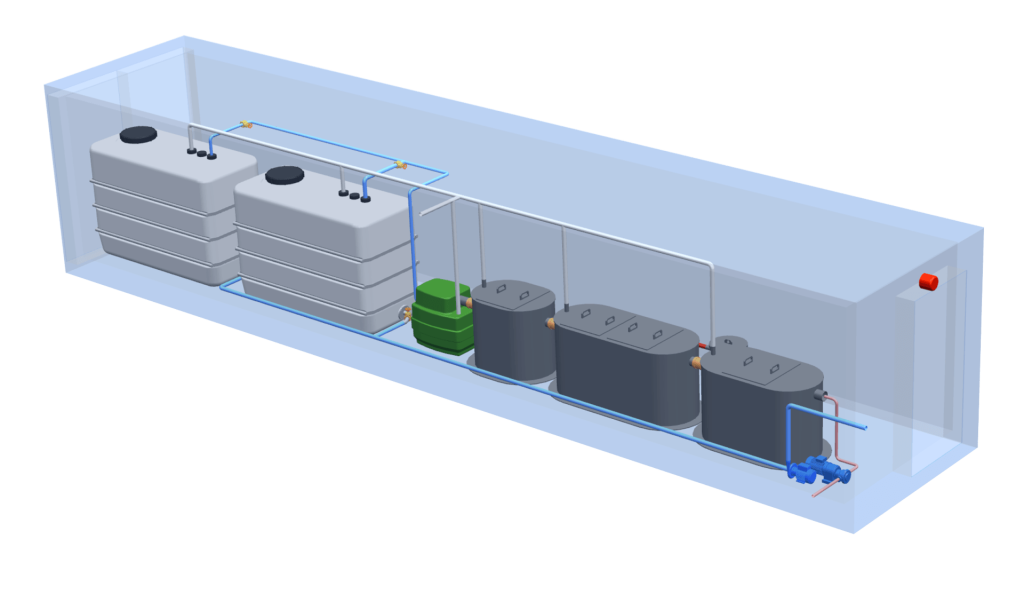

Freytech’s Oil Skimmer Package

The Freytech skimmer package is a complete solution for removing oil in many industrial settings. It comes with advanced components made to handle tough environments. This ensures top-notch oil recovery.

Key Components

At the heart of the Freytech skimmer package are its unique technologies. These use oleophilic materials to grab oil well. This means the system can quickly pull oil from water, boosting its performance.

The parts are built to last and work well in both above and below ground setups.

Mechanism of Action

The system works by collecting oil that sticks to oleophilic media. This quick process pulls out oil fast, keeping water intake low. It also makes the oil very pure.

Freytech’s systems can separate oil from water down to 0.1 PPM. This beats the industry standard for oil skimming.

Performance Metrics

The Freytech skimmer package shows its worth in real-world use. The skimmed oil is 99.7% pure and free of water. This is key for industries like auto, petrochemical, and marine, where following environmental rules is essential.

The system keeps discharge levels under 10 PPM, meeting North American standards. This shows Freytech’s dedication to top oil skimming solutions.

Performance Metrics of Freytech Equipment

Freytech skimmers show their strength in real-world use. They have high separation efficiency, which is great for many industries. They can handle oils from different sources well, improving how things work.

Separation Efficiency in Real-World Applications

Freytech’s fixed disc oil skimmers are top-notch at separating oil from water. They can remove oil down to 0.1 PPM, meeting tough standards. Plus, they work without chemicals, making them good for the environment and following rules.

Cost Savings from Efficient Oil Recovery

Freytech skimmers save money by being cheap to run and good at oil removal. They cut down on the need for expensive septic truck services. The oil they skim is very pure, at 99.7%, showing they’re cost-effective.

Comparison with Industry Standards

Freytech skimmers beat industry standards by removing oils below 5 PPM. Their design also meets North American hydrocarbon discharge limits of 10 PPM. This shows they’re not just up to par but often better than what’s expected.

Ready to talk about your needs and get expert advice? Call us at +1 (305) 372-1104. Our team is ready to share detailed information about our products. They achieve high efficiency levels, often surpassing industry standards.

Applications of Freytech Skimmers

Freytech skimmers are used in many places where separating oil and water is key. They help keep operations running smoothly and meet environmental rules. In many industries, oil and water mixtures are common. Skimmers help manage these, making work more efficient.

Industrial Processes

Industrial oil skimmers are vital for dealing with tramp oils in machining and making things. They make coolants work better, which means less damage to machines. These skimmers are reliable for mining, steel making, and food processing. They offer wastewater treatment solutions that follow environmental laws.

Wastewater Treatment

In wastewater systems, Freytech skimmers help meet North American hydrocarbon discharge limits of 10 PPM. They use advanced technology to separate oils from water, achieving less than 5 PPM. This not only avoids fines but also makes waste management cheaper.

Marine Applications

Marine areas face special challenges with oil spills and pollution. Freytech skimmers are key in handling these issues. They prevent harm to marine life and support green practices in the sea. These skimmers keep oil off the water, protecting sea creatures and following marine environmental rules.

Environmental Regulations and Standards

Keeping water clean is key for industries in North America. They must follow strict rules to avoid pollution. These rules, known as hydrocarbon limits, set the bar for what’s allowed in wastewater.

Industries must make sure their actions meet the 10 PPM discharge standards. This is to protect our environment.

Overview of North American Hydrocarbon Limits

North America has rules to control how industries affect water. These rules help keep our waterways safe for fish and plants. Companies must follow these limits closely.

Oil skimmers are important in this effort. They help remove oil from water before it’s released.

Compliance with 10 PPM Discharge Limits

The 10 PPM discharge standards are a big deal for oil skimmers. They need the right technology to meet these standards. This technology helps separate oil from water, even in tough conditions.

Choosing the right oil skimming solution is important. It helps businesses meet these discharge limits.

The Importance of 0.1 PPM Separation Efficiency

To really meet these standards, achieving a 0.1 PPM separation efficiency is needed. This ensures water is clean enough for marine life. It also helps protect our ecosystems.

Advanced oil skimmers, like those from Freytech, show it’s possible to reach such high efficiencies. This makes them key to sustainable industrial practices.

Contact Freytech Inc.

Looking for effective oil skimming and separation solutions? The team at Freytech Inc. is here to help. We welcome all inquiries about oil separators, whether you need product details or custom solutions for your operations.

How to Reach Us

Our team is dedicated to providing top-notch oil skimmer support. We know each industry faces different challenges in managing hydrocarbons. To learn more about our technology and how it can help your business, contact us anytime.

Inquiry for Oil Separator Solutions

Ready to talk about your needs and get expert advice? Call us at +1 (305) 372-1104. Our team is ready to share detailed information about our products. They achieve high efficiency levels, often surpassing industry standards.