Ever wondered how industries keep water clean and safe? or What Does ‘OWS’ Stand for in Above Ground OWS? They follow strict environmental rules. The secret is in understanding ‘OWS’ in above ground OWS systems. OWS stands for “Oil Water Separator,” a key tool to remove oil and grease from water.

These systems are vital in many fields. They make sure water released meets environmental standards. Knowing about OWS helps us see its role in keeping our water clean today.

Key Takeaways

- OWS stands for “Oil Water Separator,” central to environmental compliance.

- Above ground OWS systems effectively remove hydrocarbons from wastewater.

- Understanding OWS is essential for industries needing to meet regulations.

- OWS technology contributes to improved water quality and ecosystem protection.

- Mastering the role of OWS is key in various applications across multiple sectors.

Understanding OWS Terminology

It’s key for those in industries dealing with contaminated water to know OWS terms. OWS stands for Oil Water Separator, a tool to separate oil from water. Knowing what OWS means helps us understand its vital role in keeping our environment clean.

Definition of OWS

An OWS is a device that separates oil and hydrocarbons from water. It uses gravity and coalescence to do this. The term OWS is used a lot in industries that handle oil-contaminated waste.

OWS systems are critical for making sure industrial waste is clean. They help meet legal standards, which is important.

Importance in Environmental Protection

OWS systems do more than just follow the law. They help keep our water clean by removing harmful substances. Companies that use OWS technology are working towards a cleaner future.

By using OWS solutions, industries can reduce their impact on the environment. This helps protect our water and ecosystems for generations to come.

The Role of Oil Water Separators

Oil water separators are key in managing wastewater across different sectors. They efficiently separate oils from water. This makes them vital for following regulations and protecting the environment.

Functionality of OWS Systems

OWS systems work on gravity and coalescence. These methods help remove free oil and emulsified hydrocarbons from wastewater. They let oil rise to the surface, making it easier to collect and either reuse or dispose of safely.

This process is critical for industries aiming to keep pollution at bay and save water.

Applications in Various Industries

Oil water separators are used in many industries. Places like mechanical workshops, gas stations, manufacturing facilities, and petrochemical sectors use them. They handle oily wastewater from vehicle maintenance, industrial cleaning, and stormwater runoff.

Using these systems helps industries follow environmental rules. It also keeps local water bodies clean from pollution.

Enhanced Coalescing Technology Explained

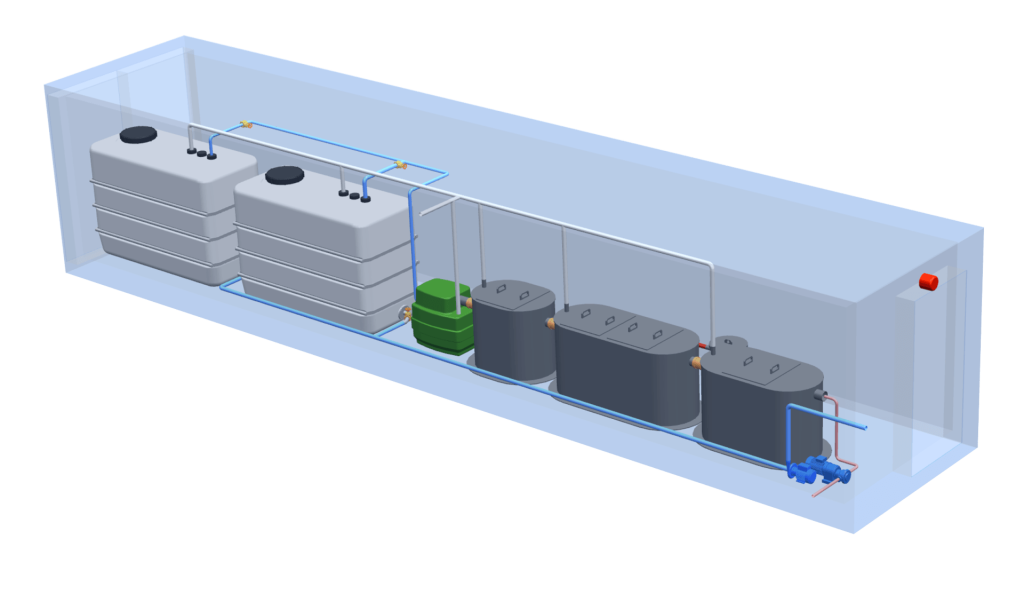

Enhanced coalescing technology is key to Freytech Inc.’s oil water separators working well. It helps separate oil from water, even in places where oil risks are high. Freytech’s tech can remove oils from water down to 5 PPM, leading the industry.

How Freytech Inc. Implements This Technology

Freytech Inc. uses the latest coalescing tech in their oil water separators. This tech uses special media for better separation. It turns small oil droplets into big ones, making oil removal more efficient and meeting tough environmental rules.

Benefits of Enhanced Coalescing

Using enhanced coalescing tech brings many advantages. Freytech’s separators not only handle emulsified oils but also make water very clean. The media can be reused, cutting down on waste and costs. This shows Freytech’s dedication to innovation and protecting the environment in oil water separation.

Regulatory Standards for Hydrocarbon Discharge

Hydrocarbon discharge rules are key to keeping our environment safe, mainly in North America. These rules make sure that water pollution doesn’t harm nature. The limit for hydrocarbons in water is 10 parts per million (PPM).

This rule is very important for oil and gas companies. They need to handle dangerous fluids carefully.

North American Hydrocarbon Discharge Limits

Companies must follow strict rules to avoid harming the environment. These rules help keep pollution low. They also push companies to use better technology to protect the planet.

Meeting and Exceeding Standards with Freytech

Freytech goes beyond what’s required to protect the environment. They achieve a separation efficiency of 5 PPM, leading the industry. For some oil components, they can get levels down to 0.1 PPM.

This shows Freytech’s strong commitment to keeping the environment safe. They make sure to follow and even go beyond all rules.

Freytech’s Separation Efficiency

Freytech is all about keeping water clean. Their advanced oil water separators work wonders. They make sure water meets strict environmental standards.

Separation Capabilities at 5 PPM

Freytech’s oil separation is top-notch, hitting 5 PPM. This is key for industries that must follow environmental rules. Their tech keeps oil levels low in wastewater, helping meet strict standards.

Achieving 0.1 PPM with Trace Oil Separation

Freytech also shines with trace oil separation, hitting 0.1 PPM. This shows their tech is cutting-edge and their commitment to the environment. They go beyond the usual, setting a high bar in water treatment.

Types of Hydrocarbons Treated by Freytech OWS

Freytech Oil Water Separators are great at handling many types of hydrocarbons. They use advanced technology to separate oil and water well. This is important for many industries that need to manage oil and water mixtures effectively.

Effectiveness Against Motor Oil and Diesel

Freytech OWS is very good at dealing with common hydrocarbons like motor oil and diesel. These separators use special technology to pull out a lot of oil from water. This is key for car and industrial uses.

They do such a good job that they meet and even beat the rules. This helps the environment and keeps things running smoothly.

Handling Jet Fuel and Other Refined Hydrocarbons

Freytech systems can also handle jet fuel and other refined hydrocarbons. This makes them useful in many different places. They help manage different fuels well and follow the rules.

The design of Freytech separators is key. It helps treat hydrocarbons effectively. This means less harm to the environment.

Advantages of Reusable Coalescing Media

Reusable coalescing media in oil water separators bring big benefits to many industries. They improve how well oil and water are separated. This also saves money and makes operations smoother for companies using them.

Cost-Effectiveness and Longevity

One key benefit is how cost-effective and durable these media are. Freytech’s separators use these long-lasting solutions. This means less money spent on maintenance and fewer replacements needed.

Companies save a lot without losing performance quality. These systems last long, making them a smart choice for businesses. They help use resources better and keep operations running smoothly.

Maintenance and Cleaning of Coalescing Media

Keeping things running at their best is important. Freytech’s reusable media is easy to clean with a spray wash. This makes maintenance simple and keeps the system efficient.

This easy upkeep extends the media’s life and keeps it working well. It’s a big plus for businesses, making Freytech’s solutions a top pick for many industries.

The Importance of Optional Oil Skimmers

Optional oil skimmers are key to making oil water separators work better. They use mechanical oil separation to drain oil into special containers with little human help. Freytech’s patented skimmer system is a great example, bringing big benefits to managing contaminants in different settings.

Benefits of Mechanical Oil Draining

This advanced method keeps the system running all the time, cutting down on maintenance stops. It automatically pulls out oil, making the process more efficient and safer for the environment. This helps businesses run smoother, leading to better productivity and less risk of breaking rules.

Impact on Oil Purity and Recycling Value

The oil collected by Freytech’s skimmers is incredibly pure, at 99.7%. This high-quality oil is more sought after and increases its value for recycling. Companies using this system can make money from recycled oil and reduce their environmental footprint. It also supports sustainable practices and boosts corporate responsibility.

Contact Freytech Inc. for Your OWS Needs

Businesses looking to improve their oil water separation should contact Freytech Inc. They offer innovative solutions tailored for different industries. Their team helps clients meet hydrocarbon discharge limits while keeping operations smooth.

Call Us Today: +1 (305) 372-1104

Reaching out to Freytech for oil water separator advice can be very helpful. They offer insights into achieving top separation efficiency. Their experts support you in making sure your facilities meet North American standards. Call Freytech today to start improving your efficiency.

Get Expert Guidance on Oil Water Separation Solutions

Leaders wanting to better manage wastewater should look at Freytech’s advanced products and services. Their solutions can keep discharge levels as low as 0.1 PPM. This meets standards like the CAN/ULC-S656. For more information, visit Freytech’s website. See how their technology can meet your needs.