What if the systems meant to protect our environment were not understood? What Does ‘OWS’ Stand for in Below Ground OWS? The term ‘OWS’ means Oil Water Separator. It’s a key technology used in below-ground systems. It helps keep our ecosystems safe by separating oil from water.

Knowing what ‘OWS’ means is key for following rules and managing resources well. This article will dive into what ‘OWS’ is and why it’s important. It will show how it helps keep our water clean for the future.

Key Takeaways

- ‘OWS’ means Oil Water Separator, vital for environmental compliance.

- Advanced OWS systems can achieve up to 95% efficiency in separating oil from water.

- Corrosion-resistant materials enhance system longevity by 30% compared to standard options.

- Real-time monitoring with smart sensors can improve leak detection by 50%.

- Effective drainage solutions reduce environmental contamination risk by 70%.

- Implementing OWS systems can cut operational costs by up to 15%.

Understanding ‘OWS’ and Its Importance

The term ‘OWS’ stands for oil water separator. It’s a key device for removing oil and hydrocarbons from water. Knowing about OWS is vital in many industries where water disposal rules apply.

Businesses must treat oils and greases before discharging into sewers. This is a must for those handling hydrocarbons.

Definition of OWS

An oil water separator separates oil from water. This reduces harmful hydrocarbon levels in wastewater. It’s a way for industries to treat water well and protect the environment.

Companies like Cleanawater provide different oil separator systems. For example, Coalescing Plate Separators can remove up to 10 ppm of oil. Vertical Gravity Separators handle flow rates from 700 to 3,000 litres.

Role in Hydrocarbon Management

The oil water separator is key in managing hydrocarbons. It makes sure oily wastewater meets standards. In industrial settings, it targets hydrocarbon pollution well.

Following local rules means regular maintenance of these separators. This ensures they work well and safely dispose of treated water.

The Functionality of Below Ground OWS

Below ground OWS systems are great at handling wastewater. They use gravity and coalescing to remove oil from water. This is key in many places, like mining truck washing.

Mechanism of Operation

Wastewater goes into the OWS system first. It has a special design for solids to settle and oils to float. The system uses special media to make oil droplets bigger.

This makes it easier to collect the oil. It’s much better than old methods that don’t work as well.

Advantages Over Other Separation Methods

Below ground OWS systems need little upkeep. They last longer and need less help than other systems. Their small size fits in tight spots, like mining areas.

They also separate oil and water very well. This is important for places that have to follow strict rules. So, they’re the best choice for many industries.

Regulatory Standards for Hydrocarbon Discharge

In North America, keeping hydrocarbon discharge limits is key for industries with oily wastewater. They must treat discharges to have less than 10 Parts per Million (PPM) of hydrocarbons. Following these rules helps companies avoid big fines and keeps the environment safe.

North American Hydrocarbon Limits

Meeting these limits can be tough, but it’s essential. Companies face challenges, like dealing with emulsified oils. Freytech Inc. offers solutions like oil-water separators that can separate hydrocarbons down to 0.1 PPM.

This technology ensures discharges are clean and meets strict rules. It also boosts the efficiency of wastewater treatment.

Importance of Compliance

Following environmental rules is vital for companies in the Clean Water Act area. It brings many benefits and helps a company’s image. Keeping records and reports is important to show you’re following the rules.

If you don’t comply, your actions could be made public. This can harm your reputation a lot. It shows how important it is to follow hydrocarbon discharge limits for a sustainable future. For more on how to meet these standards, check out Freytech’s offerings.

Enhanced Coalescing Technology Explained

Enhanced coalescing technology is key in improving oil-water separation. It helps gather small oil droplets for better removal. Freytech separators use this tech to reach separation levels as low as 0.1 PPM.

This is much better than old methods, which can’t match this level of efficiency.

How It Improves Separation Efficiency

This technology uses a reusable coalescing media. It makes oil-water separation more effective and easier to maintain. This leads to long-term savings for users.

It also makes it easier to get high-efficiency separation. This is a big help in overcoming common separation challenges.

Comparison with Traditional Methods

Enhanced coalescing technology is far better than old methods. Traditional methods often can’t get the same separation results. They leave more hydrocarbons in treated water.

This new technology helps meet environmental standards. It ensures the water discharged is very clean. It’s a big step forward in managing hydrocarbons.

Freytech Inc. Solutions

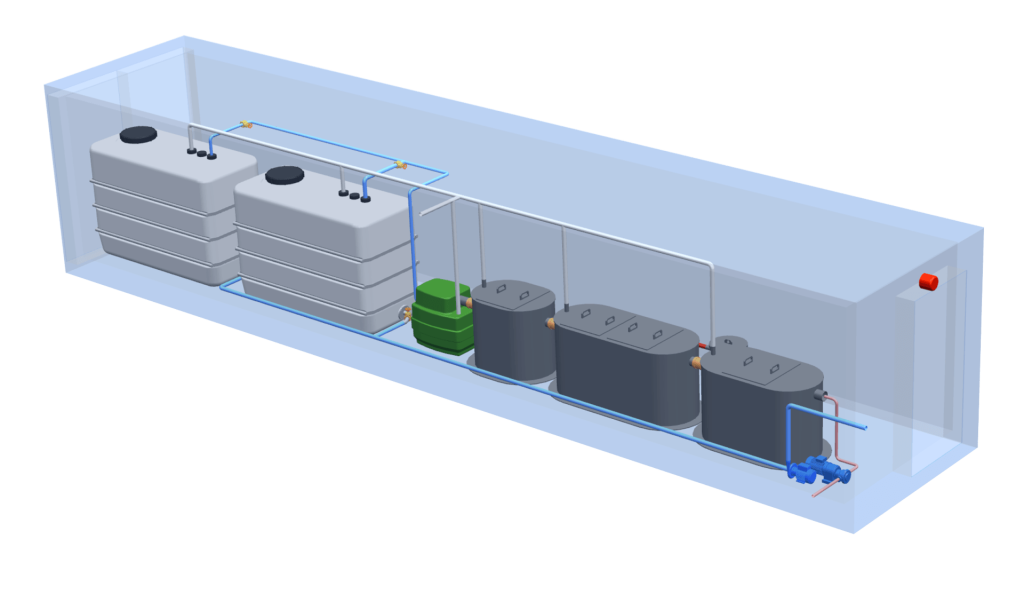

Freytech Inc. offers a wide range of oil water separator packages for different needs. These packages use the latest OWS technologies. They include advanced coalescing systems and special oil skimmers to remove hydrocarbons from water.

These products aim for high separation efficiency. They always meet the standard of less than 10 Parts per Million (PPM) for hydrocarbon discharge.

Overview of Freytech Separator Packages

The Freytech separator packages are made to fit various industries. This includes automotive repair shops and petrochemical facilities. Their below-ground systems handle free non-emulsified oils well.

They also remove trace amounts of emulsified oil up to 0.1 PPM. This meets strict regulatory standards and shows Freytech’s dedication to protecting the environment. For more information, visit Freytech’s website.

Key Technologies Used

Freytech Inc. uses the latest OWS technologies in their packages. Their patented oil skimmers remove 99.7% of oil from water. They can handle oils with specific gravity between 0.82 and 0.88.

These technologies are key for meeting today’s wastewater treatment needs. Many Freytech separators also save money by reducing the need for expensive septic truck services.

Separation Efficiency Metrics

Separation efficiency metrics are key to judging oil-water separators’ performance. They show how well these systems keep water clean from oil. Freytech’s advanced coalescing tech leads to top-notch results.

Understanding 5 PPM Performance

In North America, oil-water separation must meet 10 Parts per Million (PPM) discharge limits. Freytech’s systems go beyond this, hitting a 5 PPM separation mark. This high standard not only meets rules but also helps protect the environment.

Achieving 0.1 PPM Separation

Freytech aims even higher, reaching a 0.1 PPM separation. This shows the company’s dedication to setting high standards. Such high efficiency boosts compliance and supports environmental care.

Types of Hydrocarbons Managed

Freytech’s Oil Water Separator (OWS) systems handle different hydrocarbons important for industries. Types like motor oil and diesel fuel are found in places like car washes and gas stations. It’s key to remove these hydrocarbons well to keep our environment safe and water clean.

Common Variants Like Motor Oil and Diesel

Motor oil and diesel can pollute water when they flow into waterways through stormwater. Freytech’s systems manage these hydrocarbons to protect our water. The rules for handling these substances are strict to keep our environment safe.

Effects of Hydrocarbons on Water Quality

Hydrocarbons like motor oil and diesel harm water quality. The Environmental Management Act warns about the dangers of untreated sewage and industrial waste. Freytech’s technology helps industries meet strict limits on hydrocarbon discharge.

By using advanced separators, Freytech helps achieve very low levels of oil in water. This is good for our planet and helps keep our water safe.

The Role of Coalescing Media

The coalescing media is key in Freytech’s OWS systems. It greatly improves how oil and water mixtures are separated. This special media helps oil droplets stick together, making the separated liquids better in quality.

Reusability and Maintenance

This coalescing media can be reused, saving costs and keeping performance high. It’s easy to maintain with simple checks and cleanings. This means less downtime and more efficiency.

Spray Washing Process

The coalescing media is cleaned through a spray washing process. This removes dirt and keeps it working well for years. It’s a key part of keeping the system running efficiently and reducing the need for replacements.

Optional Features: Patented Oil Skimmer

Freytech’s oil-water separation systems include a patented oil skimmer. This feature works automatically, pulling oil from the separation chamber into a container. It makes the oil very clean, 99.7% pure, ready for recycling.

Functionality of the Oil Skimmer

The oil skimmer works well with the oil-water separator system. It helps remove unwanted hydrocarbons from wastewater. This technology cuts down on manual work, saving money and making the process smoother.

It helps facilities meet North American hydrocarbon discharge limits. They can keep their discharge under 10 Parts per Million (PPM).

Benefits of Mechanically Draining Separated Oil

The patented oil skimmer brings many benefits. It makes the work area cleaner by reducing the need for expensive septic truck services. These services often charge by the gallon for oil removal.

It also helps facilities manage oily wastewater better. This reduces downtime and supports sustainability. The skimmer can even separate oil as low as 0.1 PPM, making it key for modern wastewater management.

Recycling and Environmental Impact

Industries are now using better oil-water separation technologies. This helps recover skimmed oil from systems like those from Freytech. It turns waste into a valuable resource.

This recycling process brings big economic benefits. Companies can use waste as materials, making their operations more efficient. It’s key for reducing environmental impact and following oil waste rules.

The Value of Skimmed Oil

Recycling skimmed oil helps the environment by saving resources. It also cuts down on the need for new oils, helping the economy go full circle. This saves money and shows a company cares about the planet.

Using the right oil waste solutions is important for companies. They can use systems like Freytech’s to reduce their environmental impact. This makes their operations more sustainable and gives them an edge in the market.

Recycling skimmed oil shows how industries can change for the better. It’s all about using resources wisely and caring for the planet.