Ever thought about What Industries Use Air Compressor Oil Water Separators? or how industries deal with oil contamination? With tighter environmental rules and a focus on sustainability, oil-water separation is key. Air compressor oil water separators are essential in many fields, helping meet standards and improve processes. They play a big role in keeping air clean and operations running smoothly.

Key Takeaways

- Air compressor oil water separators are vital for industries such as manufacturing, automotive, food processing, pharmaceuticals, and oil and gas.

- About 70% of industrial air compressor systems incorporate some form of water separator to enhance air quality.

- Effective oil-water separation can lead to maintenance cost reductions of up to 30%.

- Compliance with regulations such as the EPA’s Clean Water Act is a driving force for the adoption of oil-water separators.

- Proper drainage and disposal practices help companies avoid hefty fines, ranging from $1,000 to $10,000.

- Installation of advanced oil-water separator systems can improve overall operational efficiency by up to 15%.

Introduction to Air Compressor Oil Water Separators

Air compressor oil water separators are key to better air quality and system efficiency. They remove moisture and contaminants like oil and grease from the air. This helps solve problems caused by humidity in compressed air.

Systems can get moist at rates of about 1% to 3%. This moisture can cause corrosion and damage. But, using an air compressor oil water separator can cut these risks by up to 90%. This offers big protection for your equipment and saves on maintenance costs.

Importance of Oil Water Separation

Using an air compressor oil water separator does more than just keep things clean. It boosts system efficiency by 15% by reducing wear and improving air quality. Industries like food and beverage need very clean air, often less than 10 ppm of water vapor.

Coalescing filters can take out 99% of water and particles from compressed air. This makes the air much cleaner and meets important standards.

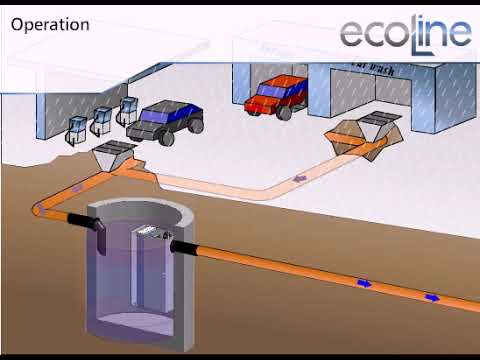

Overview of Separation Technology

There are many ways to separate oil and water, like gravity, coalescing filters, and membranes. These methods clean water well and are good for the environment. For example, desiccant dryers can make air very dry, down to -40°F.

Refrigerated dryers keep dew points between 35°F and 50°F. By choosing good air compressor oil water separators, industries can see big benefits. They also meet environmental rules.

Manufacturing Industry Applications

In the manufacturing world, managing oils and contaminants is key to success. Air compressor oil water separators are vital in metalworking and the oil and gas sectors. They help manage waste, preventing damage to equipment and ensuring environmental safety.

Use in Metalworking

Metalworking uses cutting fluids and lubricants that can pollute water. Air compressor oil water separators help remove these contaminants efficiently. They use coalescing filters to remove up to 99% of water and oil aerosols.

This improves air quality and protects machinery from rust and corrosion. Rust is a big problem for compressed air systems, affecting nearly 90% of them.

Oil and Gas Sector Requirements

The oil and gas sector has strict waste management rules. Effective oil-water separation technologies are needed to prevent oil spills and ensure safe runoff. Systems like the QWIK-PURE® separate oils from condensate, promoting responsible waste disposal.

By using these separators, companies can cut maintenance costs by up to 50%. This leads to better performance and less downtime.

Automotive Sector Needs

The automotive industry has big challenges with oil-laden wastewater from vehicle maintenance. Air compressor oil water separators are key for treating this water. They help workshops recycle oil, following environmental rules and saving resources.

Oil Recycling for Workshops

Oil recycling is critical for workshops in the automotive field. It helps manage wastewater from tasks like washing engines and draining fluids. Oil-water separators separate oils from water, making oil recycling possible. This cuts down pollution and saves money on disposal.

Environmental Compliance

Following environmental rules is vital for the automotive sector. Laws about oil-contaminated water discharge need effective treatment. Air compressor oil water separators help workshops meet these standards, keeping water sources clean. This shows the industry cares about the environment and boosts its image.

Construction and Heavy Equipment

In construction, managing fuel and oil is key to staying efficient and protecting the environment. Sites often deal with oil-contaminated water from washdowns and spills. Air compressor oil water separators are vital to handle these issues well.

They help meet regulations and keep local ecosystems safe from pollutants.

Fuel and Oil Management

Construction projects use a lot of heavy machinery, leading to oil and sediment in water. Air compressor oil water separators are essential for managing these contaminants. They separate oil from water efficiently.

These separators cut down oil content to less than 3 PPM, helping keep water clean on job sites. They use advanced coalescing technology for better separation. This reduces the chance of equipment failures and problems.

Benefits of Enhanced Coalescing

Enhanced coalescing technology makes air compressor oil water separators more effective. They can catch even tiny amounts of oil, down to 0.01 microns. This results in cleaner air and better performance for construction tools.

Using top-notch oil water separators also extends compressor life and cuts down on maintenance costs. This leads to more reliable equipment. Keeping air quality consistent is vital for construction equipment to work well and meet environmental standards.

Marine and Offshore Industries

The marine and offshore industries rely on good separation systems. These systems help manage the challenges of fueling and lubricant use. Air compressor oil water separators play a key role here.

They help reduce pollution from oil spills. This protects marine ecosystems and ensures the industries follow international standards.

Separation of Fuels and Lubricants

Air compressor oil water separators keep marine environments clean. Over 7,000 units have been installed worldwide. They meet strict standards of 15 parts per million (ppm) oil content before discharge.

Modern separators can even achieve discharges below 5 ppm. This meets the marine industry’s needs. The CS Lite model, for example, is 30% lighter than standard models. It’s a great choice for many vessels.

Importance of Clean Water Discharge

Clean water discharge is essential in marine operations. It shows the industry’s commitment to the environment. The smallest unit, the CS0500, supports vessels up to 1,600 Gross Tonnage (GWT).

As vessels get bigger, so do the needs. Models like the CS1000, CS2000, and C3000 meet these needs. They have capacities up to 3 m³/hr (792 US gal/hr) for larger vessels. This shows the marine sector’s dedication to environmental standards and operational needs.

Chemical and Petrochemical Industries

In the chemical and petrochemical industries, a lot of oily wastewater is produced. It’s important to manage this water well to follow environmental rules and protect water bodies. Air compressor oil water separators are key in this effort, helping to keep oily discharges low and meet strict environmental standards.

Handling of Refined Hydrocarbons

Coalescers are used a lot in the petrochemical sector to clean effluent water. They can remove up to 99% of water and contaminants from hydrocarbon streams. This cleaning is important to keep products pure and protect equipment.

Using air compressor oil water separators can also save money. It reduces the need for extra treatment, making operations more cost-effective.

Regulatory Standards for Discharge

Following rules is very important in the petrochemical sector. Air compressor oil water separators help meet these rules. They ensure that pollutants don’t get into water sources, helping the environment.

Companies like Freytech offer solutions for these needs. They provide air compressor oil water separators designed for the chemical and petrochemical industries.

Aerospace Applications

The aerospace industry faces unique challenges in waste management. It must follow strict rules to keep wastewater clean. Air compressor oil water separators are key in keeping operations green.

Compliance with Aviation Regulations

Aerospace needs strict rules to follow. These rules demand that wastewater is clean. Air compressor oil water separators help meet these standards, protecting water and the environment.

Separation of Jet Fuel and Oil

Aircraft maintenance often mixes jet fuel and oil with wastewater. It’s vital to separate these to avoid water pollution. Air compressor oil water separators are made for this job, keeping water safe. This shows the industry’s dedication to safety and the environment.

Food and Beverage Processing

In the food and beverage industry, keeping things clean and following rules is key. Plants often have wastewater with oils and fats, which can harm products and the environment. Air compressor oil water separators help treat this wastewater, making sure everything meets health and safety standards.

Cleanliness Standards in Production

Cleanliness is a must in food processing. Air compressors are used for tasks like moving materials and cleaning. They help keep production smooth and safe.

High-pressure air is used for cleaning, which is vital to avoid contamination. Moisture or oil in air can ruin flavors and smells, affecting product quality and increasing costs.

Oil Management Systems

Food processing needs good oil management systems. Dryers, aftercoolers, and air compressor oil water separators help manage moisture in air systems. Regular air compressor checks help find and fix contamination risks.

Companies use Class 0 certified air systems to ensure oil-free air. This makes sure products are of high quality. Adding nitrogen generators also boosts production efficiency and safety.

For more on oil management, check out air compressor oil water separators. It’s important to have strict filtration and moisture control to keep standards high in food and beverage processing.

Environmental Protection Practices

In North America, companies must follow strict rules about hydrocarbon discharge. These rules are set at 10 Parts per Million (10 PPM). Air compressor oil water separators help meet these standards by greatly reducing oil carryover.

Advanced technologies from companies like Freytech Inc. can achieve separation efficiencies as low as 5 PPM. Even 0.1 PPM for emulsified oils is possible. This leads to big benefits, like better compliance with environmental laws.

North American Hydrocarbon Discharge Limits

Discharge regulations set strict limits on oil content in wastewater. Air compressor oil water separators help industries manage oily wastewater well. This aligns their operations with environmental protection.

By using these systems, companies not only follow the law but also reduce their ecological impact. This is a big step towards a cleaner environment.

The Role of OWS in Sustainability

Oil water separators play a key role in sustainability efforts. They help manage wastewater and cut down pollution. Companies that use these technologies show their dedication to protecting the environment.

As industries work to meet environmental standards, using air compressor oil water separators is essential. It’s not just about following rules; it’s about creating a better future for all.

Why Choose Freytech Inc. for Your OWS Needs

Freytech Inc. is known for its focus on efficiency and top-notch separation in the air compressor oil water separator market. Their Enhanced Coalescing technology removes a wide range of hydrocarbons, like motor oil and jet fuel. This ensures they meet strict regulations.

Using reusable coalescing media makes maintenance simpler. This also extends the equipment’s life, saving costs over time.

Efficiency and Separation Performance

Following environmental standards is critical, as breaking them can lead to big fines from the EPA. Freytech Inc. makes sure their oil-water separators keep oil levels under 40 ppm. This meets legal standards and protects operations in many industries.

They offer systems that can handle up to 60 gallons and work in various conditions. This means they can manage condensate well, helping businesses follow the Clean Water Act.

Contact Information and Support

If you need help with oil-water separation, Freytech Inc. is ready to assist. Call them at +1 (305) 372-1104 to learn about their custom solutions. They have a strong history of improving processes in different fields, making them a reliable choice for air compressor oil water separator systems.