Did you know What Regulations Apply to Oil Water Separators? or ignoring oil water separator rules could cost your business up to $100,000 daily? Managing oily wastewater from industries like cars and planes is key. Following oil water separator rules is not just legal—it’s also a must for your wallet.

From the EPA’s federal rules to state laws, knowing and following oil water separator rules is vital. This is true for any place that deals with oily waste. Ignoring these rules can lead to big fines and even shut down your business.

The cost of not using the right technology can hurt your business’s bottom line. Not following the rules can also mean big fines. This article will dive into the main rules for oil water separators. We’ll look at what they are, why following them is important, and what happens if you don’t.

Key Takeaways

- Compliance with oil water separator regulations is critical to avoid hefty fines.

- Federal regulations set by the EPA impose strict limits on oil discharges.

- States may have additional requirements beyond federal standards.

- Effective maintenance practices are essential to prevent costly failures in oil-water separator systems.

- Non-compliance can lead to operational shutdowns and increased insurance premiums.

- Facilities must continuously inspect their oil-water separators to ensure adherence to regulations.

Understanding Oil Water Separators

An Oil Water Separator (OWS) is key in industries like mining and automotive. It uses gravity to separate oil from water. Oil floats on top, making it easy to separate.

What is an Oil Water Separator?

An oil water separator keeps oil and grease out of water. It’s important for keeping our environment safe. It uses tanks and special media to clean the water.

This makes sure the water meets legal standards. It also makes operations more efficient.

Key Components of an OWS

An OWS works well because of its parts. It has tanks to catch oil, plates to gather oil droplets, and filters to purify water. Oil skimmers remove floating oil, making the water cleaner.

These systems help industries protect the environment.

How OWS Works to Clean Water

The process starts with contaminated water going into the separator tank. Lighter hydrocarbons rise, while heavier particles fall. This is thanks to gravity.

Coalescing plate separators help catch small oil droplets. Regular upkeep keeps it working well. This protects the environment and ensures compliance.

Importance of Regulatory Compliance

Regulatory compliance is key to keeping our environment safe. It helps prevent harmful substances from getting into our land and water. By following these rules, businesses can avoid big problems and keep people healthy.

Why Regulations Matter

Following oil water separator rules is important for keeping things running smoothly. Industries like oil and gas, manufacturing, and cars make a lot of wastewater. Good separation systems help avoid big environmental problems.

If companies don’t follow these rules, they face big fines. They might also have to stop working and spend more on fixing things. This can hurt their reputation and how well they can operate.

Consequences of Non-Compliance

Not following the rules can lead to big fines, from $10,000 to $50,000. If oil water separators don’t work right, they can’t meet standards. This means wastewater can’t be clean enough, leading to legal trouble.

Ignoring maintenance can make things worse, with up to 60% of businesses facing penalties. Not following the rules costs money and can harm a company’s image and ability to work well.

Federal Regulations Governing OWS

The rules for oil water separators come from federal standards. These rules help keep our water clean. They are important for places that use a lot of oil and make products.

Overview of EPA Standards

The EPA sets rules for treating wastewater with oil. The Clean Water Act says no more than 100 ppm oil can be in water. But, local rules might be even stricter.

Many places struggle to follow these rules. This shows how important it is to keep systems working right and clean.

Clean Water Act Provisions

The Clean Water Act helps keep our water safe. It makes sure oil water separators don’t harm our water. It also encourages using water again and again.

Places have to check if they follow the law. This helps keep our water and air clean. These rules are key to keeping us and our planet healthy.

State-Level Regulations

Oil water separator rules vary by state in the U.S. Each state has its own rules for these systems. These rules help protect the environment and guide how businesses use OWS systems.

Variability Across States

Some states follow federal rules closely, while others have stricter standards. For instance, California has tough rules for oil water separators that handle hazardous materials. Knowing these rules is key for businesses to follow the law.

Examples of State Regulations on OWS

In Texas, the Title 30 Texas Administrative Code sets rules for air and water pollution. Facilities that meet certain criteria can get Permits by Rule. Others need a Standard Permit or a Title V Operating Permit for major pollutants. These rules show how states regulate oil water separators to ensure compliance.

North American Hydrocarbon Discharge Limits

Following North American hydrocarbon discharge limits is key for any oil wastewater operation. These limits, set at 10 Parts per Million (PPM), protect the environment. They also ensure that operations follow discharge regulations. Facilities must use the right technologies to meet these standards, stopping harmful pollutants from getting into water systems.

Understanding 10 PPM Limits

The 10 PPM limit is a must to avoid legal trouble and harm to the environment. Many separators, like those certified to the CAN/ULC-S656 standard in Quebec, show top-notch performance. Some models can separate contaminants below 5 PPM, far exceeding North American standards.

This high performance keeps treated water safe for the environment. It also lowers the chance of groundwater pollution.

Importance of Meeting Discharge Standards

Following discharge regulations is not just good for the environment. It also boosts a company’s reputation. Not meeting these standards can cause big financial losses, disrupt operations, and damage a company’s image. Good wastewater management is essential, more so for industries that handle a lot of hydrocarbons. It fights pollution and supports sustainability.

Freytech Inc. Technology Overview

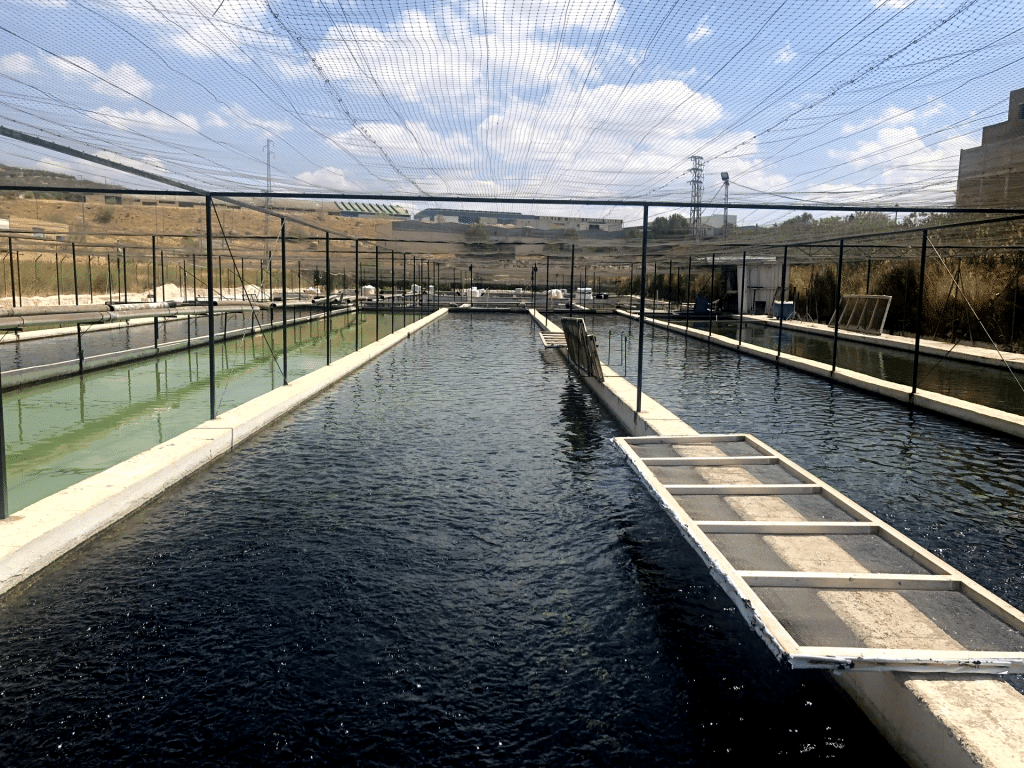

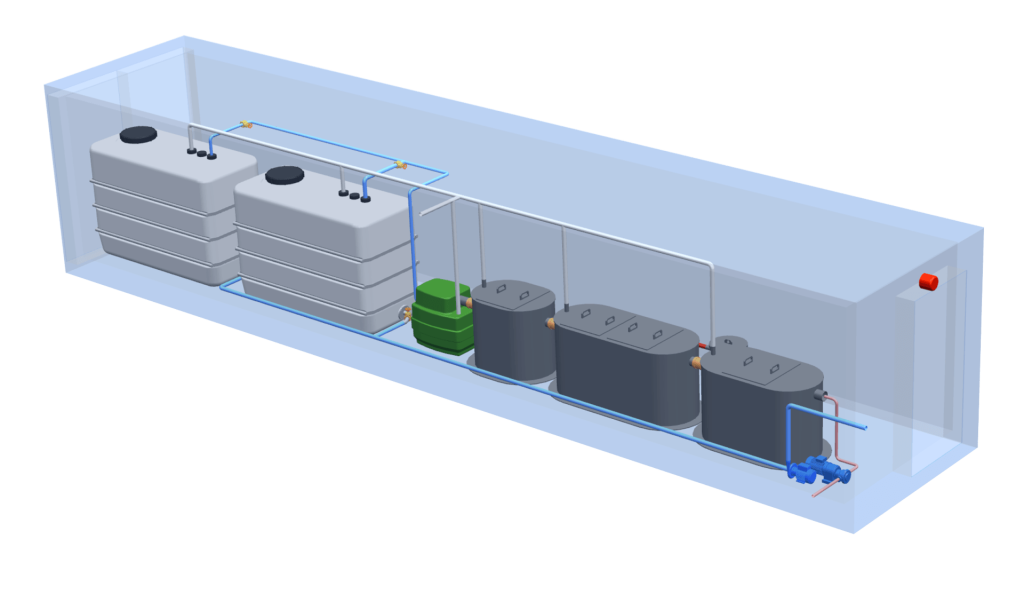

Freytech Inc. leads in oil water separation tech, using advanced coalescing tech for top-notch separation. This method is key for industries like mining and food processing. It helps remove oil from water, a big deal for clean water.

Enhanced Coalescing Technology Explained

Freytech’s oil water separators use special coalescing tech. This tech grabs oil droplets and makes them bigger. It also uses baffles to calm water, helping solid stuff settle at the bottom.

Because of this, oil droplets go up faster. This makes the separation process better.

Separation Efficiency and Performance

Freytech’s separators are the best in the business. They can get oil levels down to 5 PPM from 2000 PPM. This meets Canada’s CAN/ULC-S656 standards.

They can even get oil levels to 0.1 PPM. This meets the US EPA’s Clean Water Act for environmental safety.

Advanced Separation Efficiency Achieved

Freytech’s oil water separators are top-notch. They can separate oil down to 5 PPM under different conditions. The secret is in the coalescing plates. They increase the surface area and help oil droplets form and rise faster.

This makes the separators great for meeting environmental rules. It ensures they follow discharge standards.

Achieving 5 PPM with Freytech OWS

Freytech’s OWS systems go beyond the 15 ppm limit set by law. They use advanced methods and adjust retention times to hit 5 PPM. This shows how efficient they are, even with tough emulsions.

Businesses can keep their operations green with these systems. Keeping them well-maintained and running smoothly is key. This includes avoiding too much turbulence and ensuring good fluid flow.

Case Study: Trace Oil Separation at 0.1 PPM

A case study shows the separator’s power. It removed trace emulsified oil down to 0.1 ppm. This shows off the advanced tech in these separators.

The success in this case study highlights the system’s design and operation. Companies using these systems can reduce environmental harm. They also meet legal standards and see big operational gains. For more info, check out the Freytech Oil Water Separators website.

Types of Hydrocarbons Separated

Oil water separators (OWS) are key in treating different hydrocarbons found in many industries. They use specific methods to handle these substances, following environmental rules. By removing oil from water, OWS helps reduce harm to the environment.

Common Fuels and Oils Treated

OWS deal with motor oil, diesel, gasoline, and jet fuel. These are common in industrial areas where a lot of wastewater is made. To meet environmental rules, oil levels in water must be low, often below 10 ppm.

Using OWS, up to 90% of oily waste can be cut down. This is a big help for waste management.

The Role of Coalescing Media

Coalescing media are vital for oil water separation. They help oil droplets stick together, making them easier to separate from water. This increases the efficiency of the process.

For example, coalescing plate separators can remove up to 95% of oil droplets. This makes them very useful in many industrial settings.

Maintenance and Durability

Keeping oil water separators in good shape is key. Regular upkeep helps them work well and last longer. It also lets industries follow rules and avoid long breaks.

By following maintenance tips, you can spot problems early. This keeps your system running smoothly.

Reusable Coalescing Media

Using reusable coalescing media is a big plus. Freytech’s media can be cleaned and used again, saving money. It also keeps the system running well.

Regular checks and cleanings are important. They make sure the media works right, keeping the environment safe.

Spray-Washing for Optimal Performance

Spray-washing is a great way to clean the media. It gets rid of dirt and sludge, keeping the system reliable. Doing this regularly helps the system last longer.

It’s best to spray-wash every 3-6 months. This depends on how much oil and dirt you have. Sticking to this schedule keeps your system in top shape.

The Role of Oil Skimmers

Oil skimmers play a key role in improving the oil water separation process. They help manage waste more efficiently. By capturing floating oil, they significantly reduce water content in waste oil.

This method supports sustainable practices in many industries. It’s a step towards a cleaner future.

Benefits of Patented Oil Skimmer Technology

Oil skimmers offer more than just efficiency. Freytech’s patented technology can purify oil to 99.7%. This high purity makes recycling oil more profitable.

It also helps companies follow environmental rules better. This reduces the risk of fines for not disposing of oily wastewater properly.

Results of Efficient Skimming

Using oil skimmers leads to big improvements in managing wastewater. Different types of skimmers work for various oils, showing their flexibility. This technology helps reduce waste and makes operations cleaner and greener.

Environmental Impact and Benefits

Oil water separators are key to environmental sustainability. They help reduce the harm industrial activities do to waterways. This leads to big environmental wins.

These systems remove oil from wastewater. This makes the water cleaner, which is good for treatment plants. Industries like steel, food, and oil refining benefit a lot.

Reducing Oil Pollution in Waterways

Oil water separators improve wastewater treatment. They are vital for meeting environmental rules in many fields. The systems can handle high flow rates well.

This helps businesses avoid fines. It also keeps operations running smoothly. The technology is designed to prevent clogs, ensuring efficiency.

Recycling Used Oil and Its Value

Recycling used oil is good for the planet and saves money. Oil from these systems can be reused in factories. This makes operations cheaper.

Using systems like the Filter Pac III modules helps. It makes sure the water is good enough to be reused. This approach is both green and cost-effective.

Conclusion and Contact Information

Oil water separators are key in managing wastewater well and following environmental rules. They help treat oily wastewater, reduce harm to the environment, and meet MARPOL Annex I standards. For big vessels, keeping oil content under 15 PPM is critical. Regular checks and upkeep of OWS systems are also important to avoid leaks and keep them working right.

Choosing advanced oil water separator technologies from Freytech Inc. can improve separation, even in tough places like Antarctica. There, oily discharge is not allowed. Keeping your equipment in good shape through regular maintenance and inspections is vital. It ensures you follow the rules and makes your equipment last longer.

Contact Freytech Inc. for More Information

Want to know more about how Freytech Inc.’s solutions can improve your wastewater management? Call Freytech Inc. at +1 (305) 372-1104. Their knowledge in oil water separator technologies will help you meet all rules and protect our waterways.